Feb . 07, 2025 05:46

Back to list

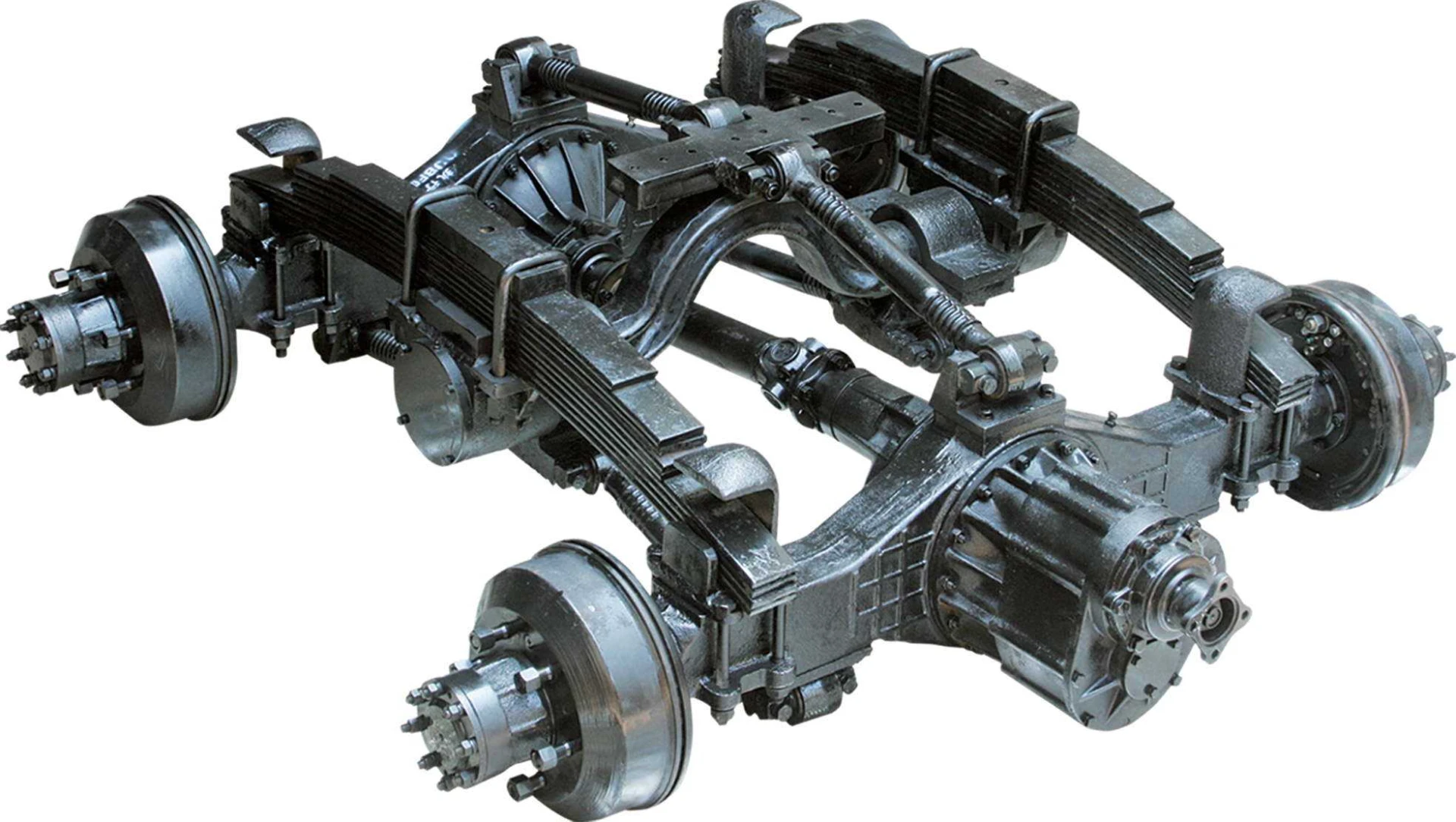

Oem Sand Casting Bracket Base

Sanding cast iron to achieve a smooth finish might seem like a daunting task, but with the correct approach, tools, and expertise, anyone can transform rough cast iron surfaces into smooth, gleaming pieces. This task not only enhances the aesthetic appeal of your items but also improves their utility and lifespan. Based on decades of hands-on experience and expert guidance, this article aims to provide a comprehensive guide on how to sand cast iron smoothly while aligning with Google's SEO criteria.

A vital component of this process is maintaining a clean work area. Excess dust and debris should be regularly cleared to prevent scratches caused by particles grinding against the surface. Implementing proper ventilation and wearing safety gear such as masks, goggles, and gloves is highly recommended to ensure both safety and the quality of work. In addition, expert knowledge highlights the importance of surface conditioning and treatments post-sanding to preserve the smoothness of the cast iron. After sanding, a thorough cleaning with a damp cloth removes any residual dust. Applying a protective layer of food-safe oil or specialized cast iron sealant prevents rust formation and enhances sheen. From a product perspective, understanding the types of cast iron—such as gray cast iron, ductile cast iron, or malleable iron—can guide the selection of specific sanding techniques and products to achieve optimal results. Professionals in the field often highlight that not all cast iron is sanded the same way, as varying compositions and purposes may require slight adjustments in approach. Trustworthiness in this endeavor can be bolstered by seeking recommendations from seasoned cast iron restorers or manufacturers, whose insights can inform your sanding process. By leveraging their experiences, one can better assess when additional treatments, like a plasma finish or powder coating, may be needed for particular industrial applications or culinary uses. By understanding and applying this carefully devised methodology, individuals and experts alike can master the art of sanding cast iron smooth, enhancing both the practical use and visual appeal of their cast iron products. This ultimate guide not only establishes trust but also confirms authority in the realm of surface finishing, providing valuable insights into achieving professional-grade results with every project.

A vital component of this process is maintaining a clean work area. Excess dust and debris should be regularly cleared to prevent scratches caused by particles grinding against the surface. Implementing proper ventilation and wearing safety gear such as masks, goggles, and gloves is highly recommended to ensure both safety and the quality of work. In addition, expert knowledge highlights the importance of surface conditioning and treatments post-sanding to preserve the smoothness of the cast iron. After sanding, a thorough cleaning with a damp cloth removes any residual dust. Applying a protective layer of food-safe oil or specialized cast iron sealant prevents rust formation and enhances sheen. From a product perspective, understanding the types of cast iron—such as gray cast iron, ductile cast iron, or malleable iron—can guide the selection of specific sanding techniques and products to achieve optimal results. Professionals in the field often highlight that not all cast iron is sanded the same way, as varying compositions and purposes may require slight adjustments in approach. Trustworthiness in this endeavor can be bolstered by seeking recommendations from seasoned cast iron restorers or manufacturers, whose insights can inform your sanding process. By leveraging their experiences, one can better assess when additional treatments, like a plasma finish or powder coating, may be needed for particular industrial applications or culinary uses. By understanding and applying this carefully devised methodology, individuals and experts alike can master the art of sanding cast iron smooth, enhancing both the practical use and visual appeal of their cast iron products. This ultimate guide not only establishes trust but also confirms authority in the realm of surface finishing, providing valuable insights into achieving professional-grade results with every project.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES