DIY Aluminum Sand Casting Techniques for Home Metalworking Enthusiasts

Sand Casting Aluminum at Home A Beginner's Guide

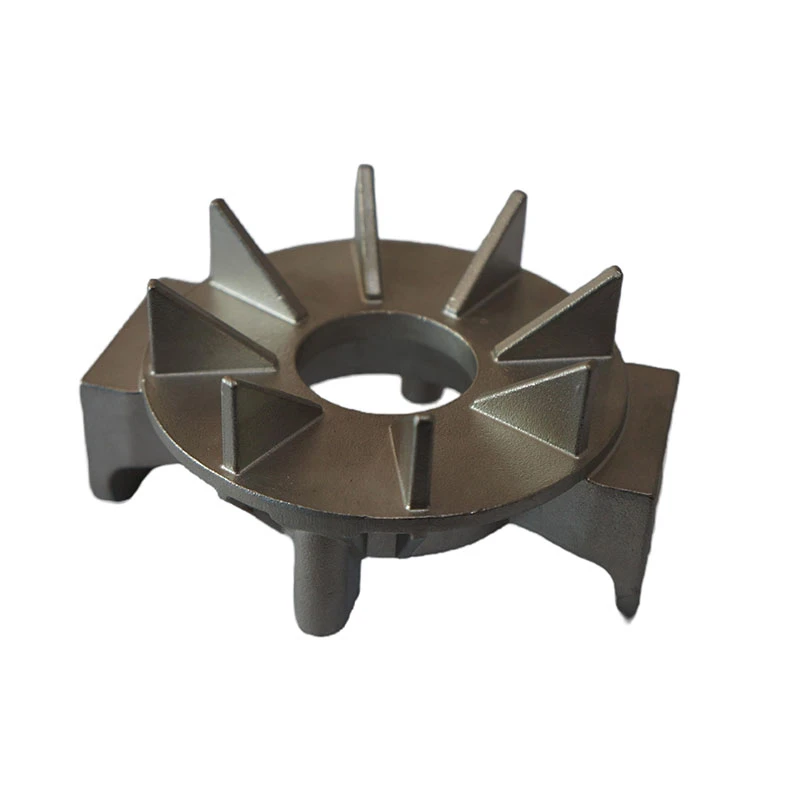

Sand casting is an ancient technique that has stood the test of time, favored for its simplicity and versatility. If you're interested in exploring the fascinating world of metalworking, aluminum sand casting at home is a perfect entry point. This article will guide you through the steps, materials, and safety tips to get you started on this rewarding hobby.

What You Need to Get Started

Before diving into the casting process, gather the essential materials and tools

1. Mold Sand This is a mixture of sand and a binding agent like clay. Make sure to choose a fine, dry sand for the best results. 2. Aluminum You can use various aluminum scraps, from old cookware to dedicated casting alloys. Make sure to clean the pieces well to remove any contaminants.

3. Melting Furnace You can build a simple furnace using a steel container and a propane torch or purchase a dedicated aluminum melting furnace.

4. Casting Flask This holds the sand mold in place. You can DIY this using wood or metal frames.

5. Pattern Material Use a durable material like wood or plastic to create the shape of the object you want to cast. The pattern should be slightly larger than the final piece due to shrinkage during cooling.

6. Handle and Safety Gear High-temperature gloves, face shield, and protective clothing are essential to protect yourself from heat and molten metal.

Steps for Sand Casting Aluminum

1. Create the Pattern Start by crafting your pattern. If you’re new, it's advisable to start small—perhaps a simple block or a decorative item. Take your time to ensure accuracy, as the quality of your pattern directly influences the final product.

2. Prepare the Sand Mold Mix your sand with a small amount of water and clay to give it binding properties. Fill your casting flask with sand, packing it tightly around the pattern. Once the top of the pattern is covered, carefully remove it to create a cavity.

3. Add Sprue and Vent Holes To allow molten aluminum to flow in and air to escape, you’ll need to create a sprue (entry point) and vent holes in your mold.

sand casting aluminum at home

4. Melt the Aluminum Using your melting furnace, heat the aluminum until it reaches a temperature of about 1200°F (650°C). Monitor the process closely and use a thermometer for accuracy. Once melted, skimming the dross (impurities that rise to the surface) will help to ensure a cleaner casting.

5. Pour into the Mold Carefully pour the molten aluminum into the sprue of your sand mold. Do this slowly to minimize turbulence, which can create defects.

6. Cool and Remove the Casting Allow the aluminum to cool and solidify for several hours, depending on the size of the casting. Once set, gently break apart the sand mold to reveal your casting.

7. Finish the Surface After removing the casting, you may need to grind or sand the surface to smooth out any imperfections or rough edges.

Safety Considerations

Safety is paramount when working with molten metal. Always work in a well-ventilated area, wear your protective gear, and have a fire extinguisher nearby. Familiarize yourself with the properties of aluminum, especially its temperature and handling requirements.

Tips for Successful Castings

- Experiment Don’t be afraid to try different designs and patterns as you gain confidence and skill. The more you practice, the better your results will be.

- Optimize Your Mold You may need to adjust your sand mixture or packing method to improve your molds. Different sands have different properties, so find what works best for you.

- Learn from Mistakes Not every attempt will be successful, and that’s part of the learning process. Analyze your results to determine what went wrong, and use it as a lesson for your next casting.

Conclusion

Sand casting aluminum at home is an enriching hobby that can yield impressive results. With the right materials, tools, and a commitment to safety, you can create custom items limited only by your imagination. So gather your supplies, ignite your passion for metalworking, and start your journey into the world of sand casting!

-

Precision Casting Prototypes and Engineering Inc – Innovating Global Manufacturing SolutionsNewsNov.24,2025

-

Precision Casting Facility: Advanced Manufacturing for Global Industries | Hairun SourcingNewsNov.23,2025

-

Leading Precision Casting Corporation: Quality Metal Components for Global IndustryNewsNov.23,2025

-

Precision Cast Rods: Definition, Applications & Future Trends in ManufacturingNewsNov.22,2025

-

Precision Cast Iron Surface Plate: The Backbone of Industrial Accuracy and QualityNewsNov.21,2025

-

Precision Aluminum Investment Casting: High-Accuracy Manufacturing for Modern IndustriesNewsNov.20,2025