Feb . 19, 2025 05:35

Back to list

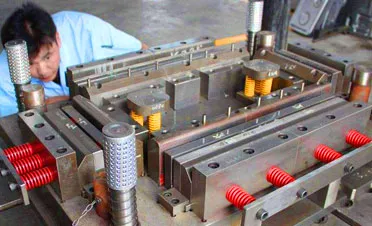

deep draw metal stamping manufacturers

Progressive die metal stamping represents a sophisticated manufacturing technique that plays a critical role in mass-producing intricate components with exceptional precision and efficiency. Known for its multifaceted capabilities, this process brings unmatched benefits to industries such as automotive, electronics, aerospace, and medical devices, ultimately setting a benchmark for modern manufacturing prowess.

Authoritativeness in progressive die metal stamping is often exhibited by industry-leading manufacturers who invest substantially in the latest technology and training. They continuously update their tools and processes to align with industry trends and evolving client requirements. Companies renowned for their progressive die stamping capabilities often have a rich portfolio showcasing a wide array of successful projects and partnerships with major industry players. These manufacturers are usually certified by international standards organizations, further solidifying their credibility and commitment to quality. Trust is cultivated through a track record of delivering products that meet or surpass client expectations. This is achieved by maintaining stringent quality control measures throughout the production cycle. Processes such as real-time monitoring, regular inspection schedules, and comprehensive testing all serve to ensure that each component adheres to specified dimensions and functions as intended. Furthermore, transparent communication with clients about project timelines, costs, and any potential challenges reinforces the reliability and integrity of the manufacturing entity. In an industry where precision and efficiency are paramount, progressive die metal stamping stands out for its effectiveness in producing high-quality components at scale. Its combination of high productivity, material efficiency, and superior accuracy makes it a preferred choice for complex manufacturing needs. As technologies advance and industries demand ever more intricate parts, the role of progressive die metal stamping will continue to evolve, driven by the accumulated experience, expertise, authority, and trustworthiness of its practitioners. Ultimately, for businesses seeking to enhance their production capabilities, progressive die metal stamping is a strategic investment. Partnering with a seasoned manufacturer not only ensures access to state-of-the-art technology and processes but also provides the assurance of quality, reliability, and innovation that are vital in today's competitive market landscape. As client demands grow and diversify, the ability of progressive die stamping to adapt and deliver remains unmatched, securing its place as a cornerstone of modern manufacturing.

Authoritativeness in progressive die metal stamping is often exhibited by industry-leading manufacturers who invest substantially in the latest technology and training. They continuously update their tools and processes to align with industry trends and evolving client requirements. Companies renowned for their progressive die stamping capabilities often have a rich portfolio showcasing a wide array of successful projects and partnerships with major industry players. These manufacturers are usually certified by international standards organizations, further solidifying their credibility and commitment to quality. Trust is cultivated through a track record of delivering products that meet or surpass client expectations. This is achieved by maintaining stringent quality control measures throughout the production cycle. Processes such as real-time monitoring, regular inspection schedules, and comprehensive testing all serve to ensure that each component adheres to specified dimensions and functions as intended. Furthermore, transparent communication with clients about project timelines, costs, and any potential challenges reinforces the reliability and integrity of the manufacturing entity. In an industry where precision and efficiency are paramount, progressive die metal stamping stands out for its effectiveness in producing high-quality components at scale. Its combination of high productivity, material efficiency, and superior accuracy makes it a preferred choice for complex manufacturing needs. As technologies advance and industries demand ever more intricate parts, the role of progressive die metal stamping will continue to evolve, driven by the accumulated experience, expertise, authority, and trustworthiness of its practitioners. Ultimately, for businesses seeking to enhance their production capabilities, progressive die metal stamping is a strategic investment. Partnering with a seasoned manufacturer not only ensures access to state-of-the-art technology and processes but also provides the assurance of quality, reliability, and innovation that are vital in today's competitive market landscape. As client demands grow and diversify, the ability of progressive die stamping to adapt and deliver remains unmatched, securing its place as a cornerstone of modern manufacturing.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES