Brass Stamping Components for Precision Engineering Applications and Custom Solutions

Brass Stamping Parts Precision Engineering for Diverse Industries

Brass stamping parts are vital components used in various industries, showcasing the versatility and efficiency of metal stamping technology. This process involves shaping brass sheets into specific forms through the application of pressure, creating components that meet stringent specifications and high standards of quality. The process is renowned for its precision, repeatability, and cost-effectiveness, making it a preferred method of production in fields ranging from automotive to electronics.

The Stamping Process Explained

The brass stamping process begins with the selection of high-quality brass sheets, chosen for their physical properties such as strength, ductility, and resistance to corrosion. These sheets are then fed into a stamping machine, where they undergo a series of operations including cutting, bending, and forming. Using dies, which are custom-made to fit the specifications of the desired parts, manufacturers can produce complex shapes and intricate designs with great accuracy.

Once the brass sheets are stamped, the components undergo secondary processes if needed. These can include deburring, plating, or surface finishing, which enhance the durability and appearance of the parts. Throughout the entire process, quality control measures are essential to ensure that the final output meets the required standards. Techniques such as visual inspection and precise measurement play a crucial role in the quality assurance of brass stamping parts.

Applications of Brass Stamping Parts

Brass stamping parts are used across a myriad of applications due to their favorable properties. In the automotive industry, they are used for connectors, brackets, and various fasteners that withstand high temperatures and mechanical stress. In electronics, brass stamping is prevalent for components such as terminals, housings, and switches, where electrical conductivity and durability are paramount.

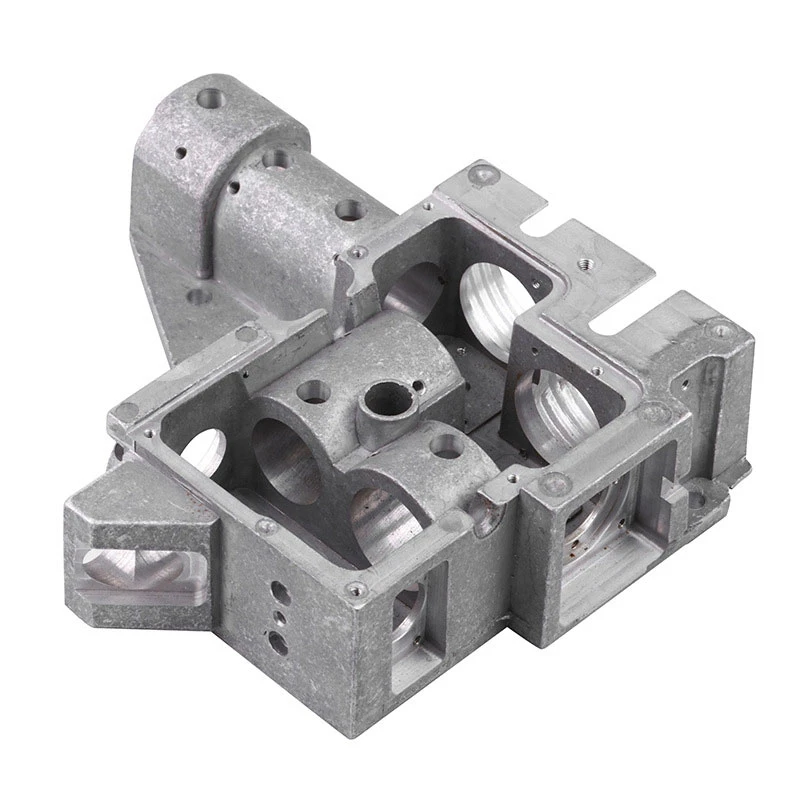

brass stamping parts

Moreover, brass’s aesthetic appeal coupled with its durability makes it an excellent choice for decorative applications. From door hardware to lighting fixtures, brass components enhance the visual appeal of products while providing the robustness needed for daily use. The plumbing industry also utilizes brass stamping parts for fittings and valves due to brass’s resistance to corrosion and its ability to seal tightly, ensuring the longevity and reliability of plumbing systems.

Advantages of Brass Stamping

One of the primary advantages of brass stamping is its ability to produce high volumes of parts with consistent quality. The automated nature of the stamping process minimizes human error and accelerates production rates, making it ideal for large-scale manufacturing. Additionally, brass is recyclable, contributing to sustainability efforts in manufacturing.

Another significant benefit is the ability to create complex geometries that are often challenging to achieve with other manufacturing methods. The precision of brass stamping not only reduces waste but also leads to significant cost savings as it eliminates the need for extensive machining or additional processing.

Conclusion

In summary, brass stamping parts are integral to numerous industries, offering a combination of strength, aesthetic appeal, and precision. The stamping process allows manufacturers to produce high-quality components that meet the demanding requirements of modern applications. As technology continues to evolve, the methods and materials used in brass stamping will undoubtedly advance, enhancing the capabilities and applications of these essential components even further. For businesses looking to incorporate high-quality brass parts into their products, understanding the advantages and applications of brass stamping is crucial for making informed decisions in production and design.

-

Precision Casting Prototypes and Engineering Inc – Innovating Global Manufacturing SolutionsNewsNov.24,2025

-

Precision Casting Facility: Advanced Manufacturing for Global Industries | Hairun SourcingNewsNov.23,2025

-

Leading Precision Casting Corporation: Quality Metal Components for Global IndustryNewsNov.23,2025

-

Precision Cast Rods: Definition, Applications & Future Trends in ManufacturingNewsNov.22,2025

-

Precision Cast Iron Surface Plate: The Backbone of Industrial Accuracy and QualityNewsNov.21,2025

-

Precision Aluminum Investment Casting: High-Accuracy Manufacturing for Modern IndustriesNewsNov.20,2025