Leading Provider of High-Quality Aluminum Die Casting Solutions for Various Industries

The Role of Aluminum Die Casting Manufacturers in Modern Manufacturing

Aluminum die casting has emerged as a critical process in the manufacturing industry, providing a unique combination of durability, precision, and cost-effectiveness. The aluminum die casting manufacturers play a significant role in various sectors, from automotive to consumer electronics, ensuring that products meet the highest standards of quality and performance. This article explores the functions of aluminum die casting manufacturers, the advantages of aluminum die casting, and the factors to consider when choosing the right manufacturer for your needs.

Understanding Aluminum Die Casting

Aluminum die casting is a metal casting process characterized by forcing molten aluminum under high pressure into a mold cavity. The molds, usually made of steel, are designed to create complex shapes with high dimensional accuracy. This process allows for the production of intricate parts that can be used in various applications, making it a favored choice among manufacturers.

Advantages of Aluminum Die Casting

1. High Strength-to-Weight Ratio Aluminum is known for its remarkable strength and lightweight properties. Aluminum die casting components can keep weight low while maintaining strength, which is crucial for industries such as automotive and aerospace where reducing weight can enhance fuel efficiency.

2. Complex Geometries The die casting process allows for the creation of intricate designs that would be difficult or impossible with other manufacturing methods. This flexibility in design empowers manufacturers to innovate and bring new products to market faster.

3. Uniformity and Reproducibility Once the die is created, a manufacturer can produce thousands of components with consistent quality. This uniformity is essential for large-scale operations where part interchangeability is critical.

4. Cost-Effectiveness Although the initial costs for tooling can be high, die casting proves to be more cost-effective in the long run due to reduced material waste and faster production times. The ability to produce high volumes of parts efficiently makes it an attractive option for many manufacturers.

5. Excellent Surface Finish Parts produced through aluminum die casting generally have a good surface finish, minimizing the need for post-casting machining. This quality reduces production time and further enhances the overall aesthetic of the components.

The Role of Manufacturers

Aluminum die casting manufacturers are responsible for several key functions that ensure the success of the casting process

- Design and Engineering Many manufacturers offer design assistance to optimize part geometry for die casting. This collaboration can significantly enhance manufacturability while reducing costs.

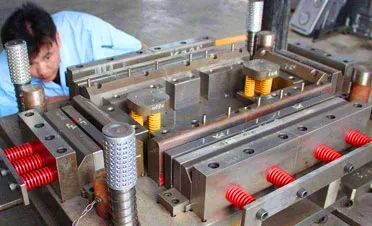

aluminum die casting manufacturer

- Tooling Development Manufacturers invest heavily in creating high-quality dies that will withstand the pressures of die casting. Durable molds are essential for producing parts with high precision and reliability.

- Production and Quality Control Effective manufacturers implement rigorous quality control measures throughout production. From material selection to final inspection, maintaining high standards is crucial in fulfilling customer requirements.

- Post-Casting Services Some manufacturers provide additional services such as machining, surface treatment, and assembly. This capability enables clients to receive a more comprehensive service, streamlining their supply chain.

Choosing the Right Manufacturer

When selecting an aluminum die casting manufacturer, several factors must be considered

1. Experience and Expertise Look for manufacturers with a proven track record in die casting. Their experience can greatly influence the quality of the final product.

2. Technology and Equipment Advanced technology and modern equipment can enhance production efficiency and product quality. It is beneficial to partner with manufacturers who stay current with industry advancements.

3. Customization A good manufacturer should be able to accommodate custom designs and specifications, ensuring that the final product meets your unique requirements.

4. Customer Support Strong customer service is crucial for a successful partnership. Effective communication and support can help troubleshoot issues and ensure timely delivery.

5. Sustainability Practices With increasing emphasis on sustainability, consider manufacturers that implement environmentally friendly practices in their production processes.

Conclusion

Aluminum die casting manufacturers play a pivotal role in modern manufacturing by producing high-quality, efficient, and cost-effective components for a myriad of applications. Their expertise and technological advancements enable industries to innovate and meet the evolving demands of the market. By carefully selecting a reliable aluminum die casting manufacturer, businesses can ensure that they receive top-notch parts that contribute to their success. As industries continue to grow and adapt, the importance of these manufacturers will only increase, driving innovation and quality in the components that shape our world.

-

crawler mounted drill rig-Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Underground Drilling Solutions, Confined Space EfficiencyNewsAug.16,2025

-

Custom OEM Couplings | Precision Machining & ManufacturingNewsAug.16,2025

-

Advanced Drilling Solutions for Confined Spaces - Baoding Hairun Machinery | Crawler Mounted Drill Rig&Confined Space ApplicationsNewsAug.16,2025

-

Drill For Confined Spaces-Crawler Drill Rig for Mining Applications|Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.16,2025

-

Crawler Mounted Drill Rig-Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Compressed Air Power&Frame SupportNewsAug.15,2025

-

Crawler Drilling Rig - Baoding Hairun|Confined Space Drilling&Mine SafetyNewsAug.15,2025