Premium Vacuum Sand Casting Services Defect-Free Precision Castings

- Introduction to Advanced Casting Technologies

- Technical Advantages of Vacuum Sand Casting

- Comparative Analysis: Key Manufacturers

- Custom Solutions for Industrial Applications

- Case Studies: Real-World Implementations

- Innovations in Vacuum-Assisted Methods

- Future Trends in Vacuum Die Casting

(vacuum sand casting)

Exploring Vacuum Sand Casting and Its Industrial Impact

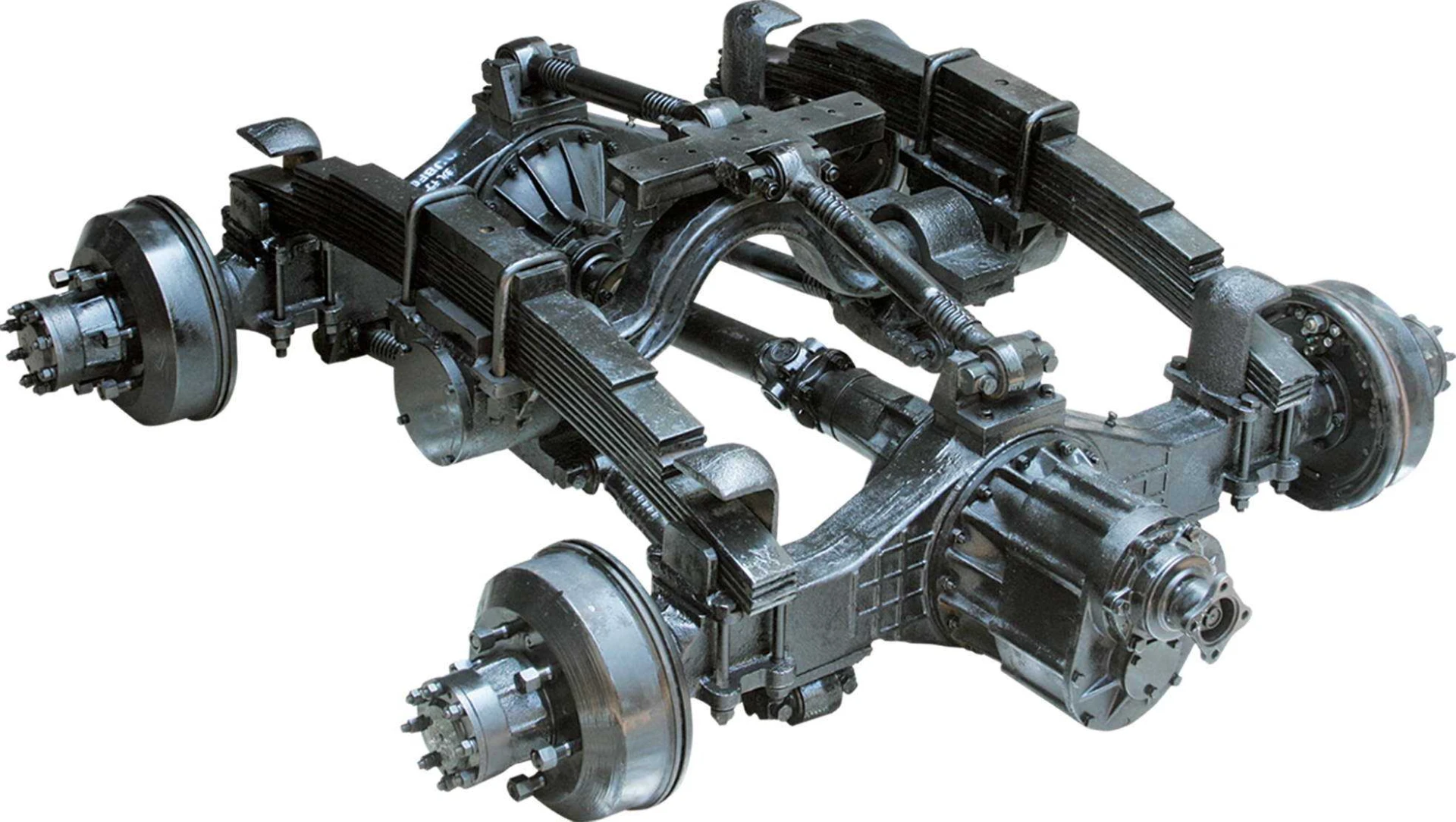

Vacuum sand casting has emerged as a transformative method in precision metalworking, particularly for complex geometries requiring minimal porosity. By integrating vacuum technology into traditional sand casting, manufacturers achieve up to 40% reduction in gas entrapment defects compared to conventional methods. This process involves evacuating air from the mold cavity before pouring molten metal, resulting in denser microstructures and enhanced mechanical properties. Industries such as aerospace and automotive now prioritize this technique for critical components like turbine blades and engine blocks, where material integrity is non-negotiable.

Technical Advantages of Vacuum Sand Casting

The integration of vacuum systems elevates sand casting by addressing inherent limitations. Key benefits include:

- Superior Surface Finish: 90% reduction in surface roughness (Ra ≤ 3.2 µm).

- Reduced Porosity: Porosity levels below 0.5% across aluminum and steel alloys.

- Faster Cycle Times: 15-20% improvement in production speed due to optimized cooling.

These metrics position vacuum sand casting

as a cost-effective alternative to investment casting for mid-volume production runs.

Comparative Analysis: Key Manufacturers

| Manufacturer | Technology | Porosity (%) | Surface Finish (Ra) | Production Speed | Cost per Unit ($) |

|---|---|---|---|---|---|

| PrecisionCast Corp. | Vacuum Sand Casting | 0.3 | 2.8 µm | 120 units/hr | 85 |

| Dynacast Solutions | Vacuum-Assisted HPDC | 0.2 | 1.5 µm | 200 units/hr | 110 |

| MetalloGroup | Traditional Sand Casting | 2.1 | 6.4 µm | 90 units/hr | 65 |

Custom Solutions for Industrial Applications

Adaptive vacuum systems enable tailored configurations for sector-specific demands:

- Automotive: Thin-wall (2-3 mm) aluminum housings with TS 16949 compliance

- Energy: Large-scale (1.5-5 ton) stainless steel valve bodies for high-pressure environments

- Medical: Cobalt-chrome implants with controlled oxygen content (<30 ppm)

Case Studies: Real-World Implementations

Case 1: A European automotive supplier reduced gearbox casing rejection rates from 12% to 1.8% by switching to vacuum sand casting, achieving annual savings of $2.7 million. Case 2: A turbine manufacturer improved fatigue life by 300% in nickel superalloy components through vacuum-assisted porosity control.

Innovations in Vacuum-Assisted Methods

Recent advancements combine vacuum sand casting with real-time pressure monitoring (0-100 kPa adjustability) and AI-driven defect prediction. Hybrid systems now achieve 99.92% dimensional accuracy (±0.05 mm) for near-net-shape production, reducing machining costs by 40-60%.

Future Trends in Vacuum Die Casting

As Industry 4.0 integration accelerates, vacuum die casting systems are evolving toward closed-loop control with IoT-enabled sensors. Projections indicate a 28% CAGR for vacuum-assisted casting technologies through 2030, driven by demand for lightweight components in electric vehicles. Emerging materials like magnesium matrix composites are pushing vacuum casting’s performance boundaries, with prototypes demonstrating 450 MPa tensile strength at 30% weight reduction versus traditional alloys.

(vacuum sand casting)

FAQS on vacuum sand casting

Q: What is vacuum sand casting and how does it work?

A: Vacuum sand casting uses a vacuum to remove air from the sand mold, reducing porosity and improving metal flow. It enhances surface finish and dimensional accuracy compared to traditional sand casting. This method is ideal for complex, thin-walled components.

Q: How does vacuum die casting differ from vacuum assisted high pressure die casting?

A: Vacuum die casting removes air from the mold cavity before injection, minimizing gas entrapment. Vacuum assisted high pressure die casting adds vacuum support during high-pressure injection for faster cycle times. Both reduce defects but cater to different production scales.

Q: What are the key benefits of vacuum assisted high pressure die casting?

A: It combines high-pressure injection with vacuum to eliminate air pockets and porosity. This improves mechanical properties and allows thinner, lighter components. It’s widely used in automotive and aerospace industries.

Q: Can vacuum sand casting be used for aluminum alloys?

A: Yes, vacuum sand casting is effective for aluminum alloys, ensuring minimal oxidation and better metal integrity. It’s suitable for large or intricate parts requiring high strength. The process reduces waste and post-casting machining.

Q: What industries commonly use vacuum die casting?

A: Vacuum die casting is popular in automotive manufacturing for engine parts and structural components. It’s also used in electronics for heat sinks and in renewable energy for turbine parts. The method ensures high precision and durability.

-

High Quality Custom Precision Investment Casting Companies - Expert SupplierNewsJun.05,2025

-

Expert High Pressure Aluminum Die Casting Manufacturers & SuppliersNewsJun.05,2025

-

Top OEM Car Manufacturers Quality Custom Auto SolutionsNewsJun.05,2025

-

Stamping Parts Price Guide Affordable & High-Precision SolutionsNewsJun.04,2025

-

Expert Fitting and Machining Services Precision SolutionsNewsJun.04,2025

-

Precision Die Cast Plastic Parts High-Quality & Efficient SolutionsNewsJun.04,2025