supply high end professional hardware stamping parts

Supply of High-End Professional Hardware Stamping Parts

In today's rapidly advancing industrial landscape, the demand for high-quality components has reached unprecedented levels. Among these components, hardware stamping parts play a pivotal role, particularly in sectors that require precision and durability. This article explores the significance of high-end professional hardware stamping parts, the intricacies of their manufacturing, and their applications across various industries.

Understanding Hardware Stamping Parts

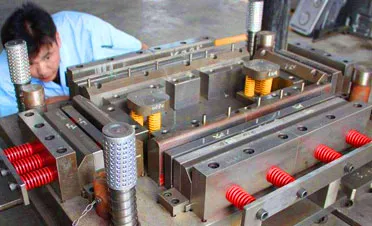

Hardware stamping is a manufacturing process that involves bending and cutting sheet metal into desired shapes using dies and presses. This method is highly favored for its ability to produce large volumes of parts with exceptional precision. High-end professional hardware stamping parts are typically made from materials such as stainless steel, aluminum, and high-carbon steel. These materials are chosen for their strength, resistance to corrosion, and suitable for various environmental conditions.

The stamping process can involve several techniques, including blanking, piercing, bending, and forming. Each method is tailored to meet specific design requirements, ensuring that the final product not only fits perfectly but also adheres to stringent quality standards. As industries increasingly move toward automation and mass production, the need for finely crafted stamping parts has escalated, underscoring the importance of advanced manufacturing techniques and technology.

Applications of High-End Stamping Parts

High-end hardware stamping parts find applications across a myriad of industries. In the automotive sector, for instance, these parts are critical for manufacturing components like brackets, chassis, and various other structural elements. The automotive industry prioritizes safety and performance, making the reliability of stamped parts paramount. Stamped parts for cars must meet rigorous testing standards to ensure they can withstand extreme conditions, thereby protecting passengers and enhancing vehicle integrity.

In the electronics industry, precision stamped parts are crucial for the assembly of devices such as smartphones, computers, and home appliances. Connectors, switches, and housing components all require precise measurements to function correctly. High-end stamping ensures that these components fit seamlessly, minimizing the risk of malfunctions and enhancing product longevity.

supply high end professional hardware stamping parts

Additionally, the aerospace industry demands the highest quality in stamped parts, given the enormous pressures and stresses that aircraft components undergo. Every stamped part, from brackets to support structures, must meet stringent regulatory standards. Manufacturers of high-end hardware stamping parts often obtain certifications such as ISO 9001 and AS9100, which reflect their commitment to quality and safety in aerospace applications.

Technological Advancements in Stamping

As technology evolves, so does the hardware stamping industry. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the way manufacturers approach the stamping process. These technologies enable precise simulations and optimizations before physical production begins, reducing waste and production costs.

Moreover, advancements in die-making technology have significantly improved the efficiency of the stamping process. Modern die designs allow for quicker changeovers and production runs, enabling manufacturers to switch between different part designs with minimal downtime. This flexibility is crucial in today’s fast-paced market, where customization and rapid delivery times are often key determinants of success.

The Future of Hardware Stamping Parts

Looking ahead, the future of high-end professional hardware stamping parts appears promising. As industries continue to evolve towards increased automation, the demand for precision-engineered components will only grow. Manufacturers who invest in advanced technologies, focus on research and development, and prioritize quality assurance will likely lead the market.

Sustainability is also becoming a core focus, with manufacturers looking to minimize waste and energy consumption during the stamping process. The adoption of eco-friendly materials and processes aligns well with the global movement towards sustainable manufacturing, allowing companies to not only enhance their competitive edge but also fulfill their corporate social responsibility.

In conclusion, high-end professional hardware stamping parts are an integral component of modern manufacturing, playing a vital role in various industries. Through the application of advanced technologies and a relentless commitment to quality, manufacturers are positioned to meet ongoing demands while paving the way for future innovations. As we move forward, the focus on precision, efficiency, and sustainability will define the landscape of hardware stamping for years to come.

-

Pros & Cons of Sand Casting: Products & ApplicationsNewsAug.19,2025

-

Advanced Crawler Drilling Rig for Confined Spaces-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.18,2025

-

Crawler Drilling Rig- Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Pneumatic Power,Frame-Supported DesignNewsAug.18,2025

-

Precision OEM Valve Body Castings for Superior PerformanceNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun Machinery | Underground Drilling SolutionsNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun | Pneumatic Safety, Mining EfficiencyNewsAug.17,2025