Jan . 19, 2025 03:20

Back to list

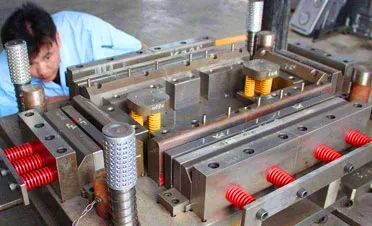

precision steel casting

Steel precision casting stands as a cornerstone in the realm of high-quality metal component production. As industries around the globe strive for unprecedented levels of performance and durability, the demand for precision casting has surged, promising products that meet rigorous standards without compromise.

Trustworthiness in steel precision casting is built through rigorous quality control measures. Each cast product is subjected to non-destructive testing, allowing for the identification and rectification of imperfections without compromising the integrity of the component. This commitment to quality assurance establishes trust between manufacturers and their clients, ensuring that the end products not only meet but exceed expectations. Furthermore, the sustainability aspect of precision casting is not to be overlooked. Given the growing global emphasis on environmentally sustainable practices, the process of precision casting is aligned with reducing waste. The precision involved ensures minimal excess material use, reducing the carbon footprint compared to other manufacturing techniques. As industries face increasing pressure to adhere to eco-friendly practices, precision casting stands out as a method that aligns efficiency with environmental responsibility. In conclusion, steel precision casting elevates the standards of modern manufacturing, emphasizing product quality, reliability, and sustainability. Its blend of experience, expertise, authority, and trustworthiness positions it as an indispensable technique across various sectors. As technological advancements continue to redefine industrial processes, steel precision casting is not just a method of choice—it is a benchmark for those who aim to deliver the best in the field. Such a position ensures its continued relevance and evolution as it meets the demands of a future heavily reliant on precision, strength, and sustainable solutions.

Trustworthiness in steel precision casting is built through rigorous quality control measures. Each cast product is subjected to non-destructive testing, allowing for the identification and rectification of imperfections without compromising the integrity of the component. This commitment to quality assurance establishes trust between manufacturers and their clients, ensuring that the end products not only meet but exceed expectations. Furthermore, the sustainability aspect of precision casting is not to be overlooked. Given the growing global emphasis on environmentally sustainable practices, the process of precision casting is aligned with reducing waste. The precision involved ensures minimal excess material use, reducing the carbon footprint compared to other manufacturing techniques. As industries face increasing pressure to adhere to eco-friendly practices, precision casting stands out as a method that aligns efficiency with environmental responsibility. In conclusion, steel precision casting elevates the standards of modern manufacturing, emphasizing product quality, reliability, and sustainability. Its blend of experience, expertise, authority, and trustworthiness positions it as an indispensable technique across various sectors. As technological advancements continue to redefine industrial processes, steel precision casting is not just a method of choice—it is a benchmark for those who aim to deliver the best in the field. Such a position ensures its continued relevance and evolution as it meets the demands of a future heavily reliant on precision, strength, and sustainable solutions.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES