Custom Stamped Parts Manufacturing for Quality Industrial Applications and Solutions

The Importance of Stamping Parts Factories in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, stamping parts factories play a crucial role. These establishments are responsible for producing high-precision components that are integral to various industries, including automotive, aerospace, electronics, and machinery. The process of metal stamping involves various techniques to shape, cut, and form metal sheets into specific designs and specifications that meet the demands of modern product manufacturing.

Understanding the Stamping Process

Stamping is a manufacturing process that employs a range of tools and machinery to create parts from metal sheets. This process typically includes methods such as blanking, punching, bending, and embossing. Metal stamping can be performed using progressive dies, transfer dies, or single-station dies, each suited for different production requirements.

The stamping process begins with the raw material, usually in the form of a flat sheet of metal. The sheet is fed into the stamping machine, where a die presses down to cut and shape the metal into the desired part. This high-speed operation can produce thousands of components in a single day, making it an efficient choice for mass production.

Applications Across Industries

One of the primary benefits of stamping parts factories is their versatility in producing components for various industries. In the automotive industry, for example, stamping is essential for creating parts such as brackets, frames, and body panels. These components must meet stringent quality and safety standards, and stamping processes are capable of delivering the precision and reliability required.

In the electronics sector, metal stamping is used to manufacture connectors, switches, and housings that ensure the proper functioning of electronic devices. The aerospace industry also relies on stamping for producing lightweight yet durable components that withstand extreme conditions and contribute to overall aircraft performance.

The construction industry benefits from metal stamping as well, with factories producing parts for structural applications, roofing, and fasteners that enhance the safety and integrity of buildings

.stamping parts factory

Advantages of Stamping Parts Factories

One of the key advantages of stamping parts factories is their ability to provide high-volume production with consistent quality. The automated stamping process minimizes human error and allows for tighter tolerances, ensuring that each piece meets the required specifications. This consistency is crucial in industries where even the smallest deviation can lead to significant issues, such as safety concerns in automotive manufacturing.

Additionally, stamping is a cost-effective solution for producing large quantities of parts. The initial setup costs for dies and machines can be high, but once the tooling is in place, the cost per unit significantly decreases. This makes metal stamping an attractive option for manufacturers looking to scale their production without sacrificing quality.

Moreover, advancements in technology have led to the development of more sophisticated stamping techniques, including the incorporation of computer numerical control (CNC) technology. This innovation allows for even greater precision, complex shapes, and more efficient production processes, ultimately leading to reduced waste and increased sustainability in manufacturing.

Future Trends in Stamping Parts Factories

As industries continue to evolve, stamping parts factories must adapt to new challenges and opportunities. One notable trend is the increasing demand for lightweight materials that enhance fuel efficiency in automotive and aerospace applications. Stamping technology is evolving to accommodate these materials, such as aluminum and advanced alloys, ensuring that factories remain competitive.

Furthermore, the shift towards Industry 4.0 and smart manufacturing is influencing stamping operations. Factories are integrating IoT devices, data analytics, and automation to streamline processes, enhance product quality, and reduce downtime.

Conclusion

In conclusion, stamping parts factories are an indispensable part of modern manufacturing. Their ability to produce high-quality, precise components efficiently serves a wide range of industries and is essential for meeting the demands of today’s fast-paced market. As technology advances, these factories will continue to innovate, ensuring they remain at the forefront of manufacturing excellence. With the increasing focus on sustainability and efficiency, stamping parts factories will undoubtedly play a critical role in shaping the future of manufacturing.

-

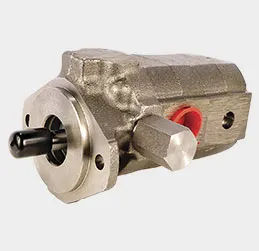

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025