small part metal stamping

Small Part Metal Stamping An Essential Process for Precision Manufacturing

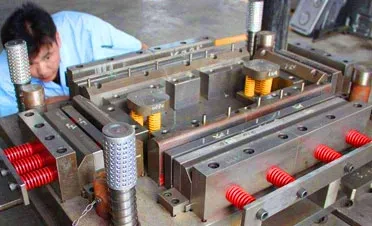

In modern manufacturing, precision and efficiency are key drivers of success. One critical process that fulfills these requirements is metal stamping, particularly when it comes to small parts. Metal stamping is a manufacturing process that involves placing flat sheets of metal into a stamping press where they can be shaped, cut, or formed into specific geometries. The method is widely used across various industries, including automotive, aerospace, electronics, and medical devices.

Understanding Metal Stamping

Metal stamping involves several techniques, including punching, blanking, bending, and embossing, each tailored to create complex designs and achieve exact specifications. These techniques are beneficial when manufacturing small parts, as they allow for high levels of precision and repeatability. Small part metal stamping is ideal for producing intricate components that require tight tolerances and consistent quality.

Advantages of Small Part Metal Stamping

1. High Precision and Consistency One of the primary benefits of small part metal stamping is the ability to produce components with high precision. This is particularly important in industries where even minor deviations can lead to significant issues, such as in the aerospace or automotive sectors. Metal stamping can achieve tolerances as tight as ±0.001 inches, ensuring that parts fit and function as intended.

2. Cost-Effectiveness Once the initial setup costs are covered, the per-unit price of small stamped parts can be remarkably low. This is due to the speed at which a stamping press can operate, producing large quantities of parts in a relatively short amount of time. Additionally, metal stamping generates minimal waste, further enhancing its cost-effectiveness.

3. Material Versatility Small part metal stamping can be performed on a variety of materials, including stainless steel, aluminum, brass, and even specialized alloys. This versatility allows manufacturers to select materials best suited for the specific requirements of their product, including factors like weight, strength, and corrosion resistance.

4. Complex Geometries and Designs Stamping allows for the creation of complex designs that would be difficult or impossible to achieve using traditional machining techniques. Features such as holes, slots, and intricate bends can be incorporated into small parts, enhancing their functionality and performance.

small part metal stamping

Applications of Small Part Metal Stamping

Small part metal stamping is utilized in many applications across different industries. In the automotive industry, it is used to produce components like brackets, clips, and housings that must withstand rigorous stress and environmental conditions. In electronics, small stamped parts are integral to devices, serving as connectors, switches, and circuit components.

In the medical field, precision stamped components are critical for instruments and devices where accuracy can impact patient safety. The aerospace industry also relies on stamped metal parts for their lightweight, strength, and reliability, as components must often meet stringent regulations and performance standards.

The Future of Small Part Metal Stamping

As technology continues to advance, the realm of small part metal stamping is evolving. Innovations in automation, such as the use of robotics and advanced software for design and production, are streamlining the stamping process, further increasing efficiency and reducing costs. Additionally, the growing trend towards additive manufacturing and hybrid techniques—which combine stamping with other methods—promises to expand the capabilities of traditional stamping technologies.

Sustainability is another critical factor shaping the future of metal stamping. Manufacturers are now looking for ways to minimize their ecological footprint, adopting practices that reduce waste and improve energy efficiency. Companies that embrace sustainable practices not only contribute to the environment but can also appeal to a more eco-conscious consumer base.

Conclusion

Small part metal stamping is an indispensable process in modern manufacturing, playing a crucial role in the production of precision components for a wide range of applications. Its advantages, including high precision, cost-effectiveness, material versatility, and ability to produce complex geometries, make it a preferred choice for many industries. As technology progresses and the focus on sustainability grows, small part metal stamping will remain at the forefront of efficient and innovative manufacturing solutions.

-

Aluminium Pressure Die Casting High-Precision & Durable Solutions for Complex PartsNewsJul.08,2025

-

Top Aluminum Sand Castings Manufacturer – Precision Green Sand Castings for Industrial NeedsNewsJul.08,2025

-

Precision Lost Wax Casting Quotes – High Accuracy Custom Parts Lost Wax Precision Casting ServicesNewsJul.07,2025

-

High-Quality Sand Used for Casting - Superior Sand for Sand Casting ProcessesNewsJul.07,2025

-

China Supply High End Metal Stamping Parts Sino - Precision Manufacturing FactoryNewsJul.06,2025

-

High-Quality Automotive Investment Casting Services Precision & Sand Casting SolutionsNewsJul.06,2025