Precision Valve Solutions for Optimal Service Efficiency and Reliability in Industrial Applications

Precision Valve Services Ensuring Quality and Reliability in Fluid Control

In today's industrial landscape, where efficiency and reliability are paramount, precision valve services play a critical role in maintaining the integrity of fluid control systems. These services are essential across various sectors, including oil and gas, chemical processing, water treatment, and many others, where the management of flow, pressure, and temperature is vital. This article explores the importance of precision valve services, the technology involved, and the benefits they provide to businesses.

Understanding Precision Valves

Precision valves are specialized devices designed to regulate the flow of liquids and gases with utmost accuracy. Unlike standard valves, precision valves are engineered to deliver consistent performance even under challenging conditions. These valves are often utilized in applications where the margin for error is minimal, such as in pharmaceutical manufacturing, semiconductor fabrication, and aerospace systems. The functionality of these valves can mean the difference between operational success and costly failures.

The Role of Precision Valve Services

Precision valve services encompass a wide range of activities aimed at maintaining and enhancing the performance of these critical components. Key service offerings typically include

1. Inspection and Testing Regular inspection and testing of precision valves ensure that they operate correctly and safely. Technicians use advanced diagnostic tools to assess valve performance, identify leaks or malfunctions, and determine whether a valve meets industry standards.

2. Repair and Maintenance Over time, valves can experience wear and tear that affects their performance. Precision valve services include comprehensive repair options, from replacing seals and gaskets to overhauling entire valve assemblies. Preventive maintenance programs can also be established to extend the lifespan of valves and prevent unplanned downtime.

3. Calibration and Optimization For applications requiring exact control of flow and pressure, calibration is essential. Precision valve services include adjusting valves to ensure they function within specified parameters, optimizing their performance to reduce energy consumption, and improving system efficiency.

precision valves services

4. Replacement and Upgrading When repairs are no longer feasible, precision valve services provide options for valve replacement. Upgrading to more advanced technology can lead to significant improvements in performance and reliability. Service providers often offer consultations to help clients select the best valve solutions for their specific needs.

The Benefits of Precision Valve Services

Investing in precision valve services offers numerous advantages for businesses

- Enhanced Reliability Regular servicing and maintenance reduce the likelihood of unexpected failures, leading to more reliable operations. This reliability translates to less downtime and increased productivity.

- Cost Savings By preventing failures through routine maintenance, businesses can avoid costly repairs and interruptions. Moreover, precision valves that operate efficiently can contribute to lower energy costs.

- Regulatory Compliance Many industries are subject to stringent regulations regarding the handling and control of fluids. Precision valve services help ensure compliance with these regulations, minimizing the risk of legal issues and associated fines.

- Expertise and Knowledge Professional valve service providers bring knowledge and expertise that internal teams may lack. Their experience allows them to identify potential issues early and recommend the most effective solutions.

Conclusion

In summary, precision valve services are a vital aspect of maintaining the efficiency and reliability of fluid control systems across various industries. With a focus on inspection, maintenance, calibration, and replacement, these services help businesses minimize risks, enhance performance, and achieve long-term success. As industries continue to evolve, embracing precision valve services will remain essential for organizations aiming to uphold high standards of quality and reliability in their operations. By prioritizing the upkeep of precision valves, companies can ensure they are prepared to meet the challenges of the future with confidence.

-

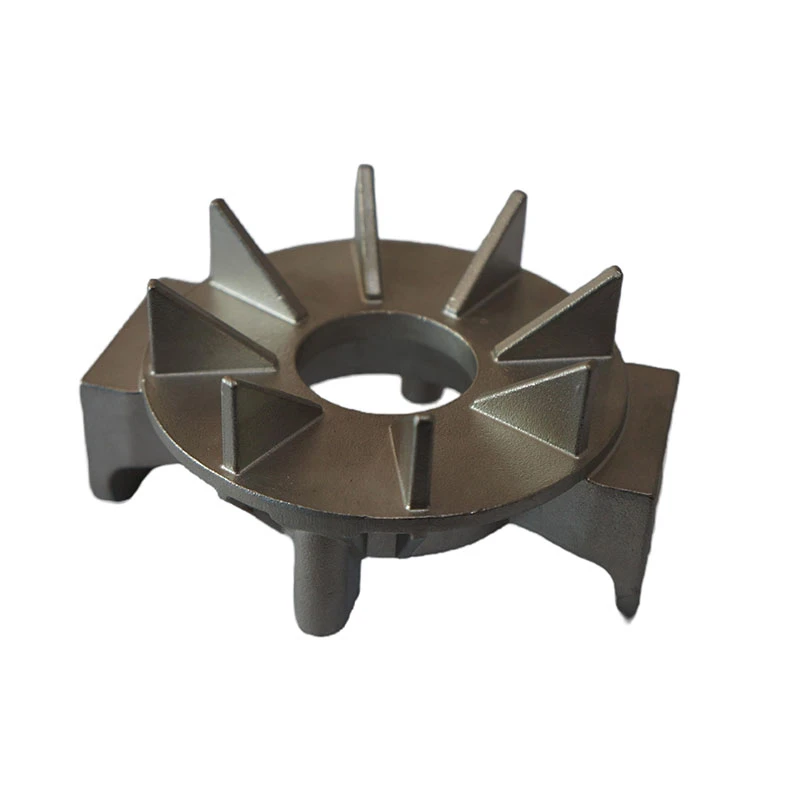

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025