Top Manufacturers of Precision Investment Casting for Quality Parts Production

The Rise of Precision Investment Casting Manufacturers

In today's rapidly evolving manufacturing landscape, precision investment casting has emerged as a key player across various industries. This method provides a combination of high accuracy, intricate detail, and excellent surface finish, making it a preferred choice for producing complex components. As the demand for precision components increases, so does the significance of precision investment casting manufacturers. This article delves into the world of precision investment casting, its advantages, and the emerging trends shaping its future.

Understanding Precision Investment Casting

Precision investment casting, also known as lost-wax casting, is a sophisticated manufacturing process that involves creating a wax model of the desired component. This model is then coated in a ceramic material and heated to remove the wax, forming a mold. Molten metal is poured into this mold to create the final product. This technique is prized for its ability to produce parts with exceptional dimensional accuracy and intricate geometries that would be challenging to achieve with traditional casting methods.

Advantages of Precision Investment Casting

One of the primary advantages of precision investment casting is its ability to produce components with tight tolerances. Manufacturers often require parts that meet stringent specifications, and investment casting can achieve tolerances as tight as ±0.005 inches. This level of precision reduces the need for extensive machining, which not only saves time but also minimizes material waste.

Another significant benefit is the ability to cast complex shapes. Many industries, such as aerospace, automotive, and medical, require components that possess intricate details. Precision investment casting enables manufacturers to create complex geometries that are not feasible with other methods. This capability expands the design possibilities for engineers and designers, fostering innovation and efficiency.

Moreover, investment casting is compatible with a wide range of metals and alloys, including stainless steel, aluminum, and titanium. This versatility allows manufacturers to tailor materials to specific applications, enhancing the performance and longevity of the parts produced.

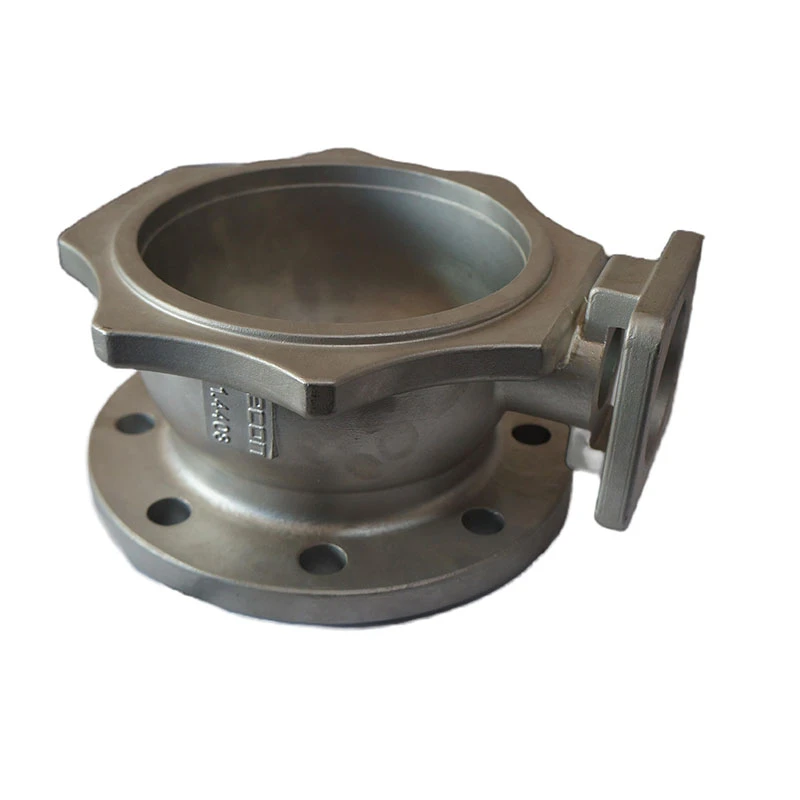

precision investment casting manufacturers

Market Trends and Innovations

As industries continue to push for higher efficiency and sustainability, precision investment casting manufacturers are embracing various trends and innovations. One notable trend is the integration of advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies enable manufacturers to simulate the casting process, optimize designs, and improve production efficiency.

Another critical development is the adoption of additive manufacturing techniques in conjunction with investment casting. This hybrid approach allows manufacturers to produce complex patterns using 3D printing, streamlining the mold-making process. By leveraging additive manufacturing, precision investment casting can further reduce lead times and costs while enhancing the overall quality of the final product.

Sustainability is also becoming an increasingly important focus within the industry. Manufacturers are exploring eco-friendly materials and processes to minimize environmental impact. Efforts to recycle scrap metal and reduce energy consumption during the casting process are gaining traction, as companies aim to improve their sustainability profiles and comply with stricter regulations.

The Future of Precision Investment Casting Manufacturers

The future of precision investment casting manufacturers looks promising, with ongoing advancements shaping the industry landscape. As technology continues to evolve, manufacturers are expected to enhance their capabilities, optimize production processes, and improve the quality of their products.

In conclusion, precision investment casting is a crucial manufacturing method that offers numerous advantages, including high precision, the ability to create complex shapes, and material versatility. As industries demand more efficient and sustainable solutions, precision investment casting manufacturers are poised to lead the way in innovation and quality. By embracing new technologies and sustainable practices, these manufacturers will not only meet current market demands but also pave the way for a more efficient and environmentally friendly future in manufacturing. The journey is just beginning, and the potential for growth and innovation in precision investment casting is limitless.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025