Precision Pressure Casting | Aluminum & Vacuum Die Casting Products

Understanding Pressure Casting in Modern Manufacturing

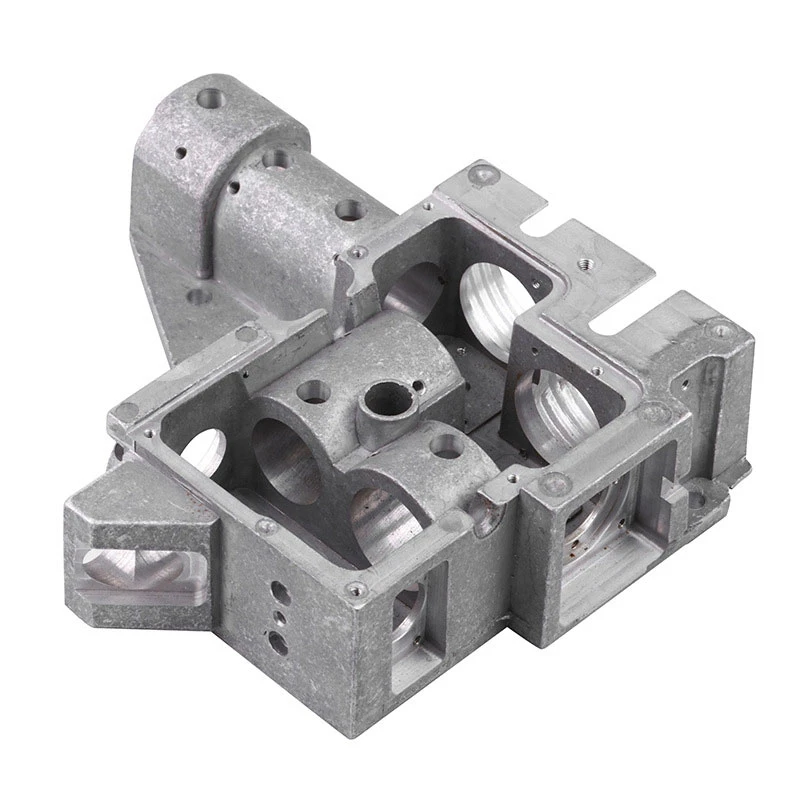

The landscape of high-volume metal component manufacturing is continually evolving, with pressure casting standing out as a pivotal technology for producing intricate parts with exceptional precision and surface finish. This advanced die casting method involves forcing molten metal, typically non-ferrous alloys such as aluminum, zinc, or magnesium, into a mold cavity under high pressure. The rapid solidification under pressure minimizes porosity and enhances the mechanical properties of the finished product, making it indispensable across diverse industrial sectors. Our focus, Oem Die Casting Piston Fittings, exemplifies the capabilities of this process, providing robust and dimensionally stable components crucial for demanding applications. Its efficiency in producing net-shape components significantly reduces the need for extensive post-processing, offering substantial cost savings and faster time-to-market.

Beyond conventional approaches, innovations like vacuum die casting are pushing the boundaries of what's possible, enabling the production of even higher quality parts with fewer defects. This variant specifically removes air from the die cavity before injection, further reducing trapped gas porosity and improving the mechanical integrity, weldability, and heat treatability of castings. This advancement is particularly beneficial for safety-critical components or those requiring superior structural integrity. The precision offered by these methods ensures that components like piston fittings can operate reliably under extreme conditions, embodying the core advantages of high-pressure manufacturing techniques.

The Pressure Casting Process: A Technical Deep Dive

Detailed Manufacturing Flow and Parameters

The manufacturing process of pressure casting begins with the preparation of the molten metal, which is heated to a precise temperature to ensure optimal flow characteristics. For Oem Die Casting Piston Fittings, a high-quality aluminum alloy is typically used, renowned for its excellent strength-to-weight ratio and corrosion resistance. The molten aluminum is then transferred to a shot chamber, where a hydraulic piston rapidly injects it into a steel die cavity under intense pressure, typically ranging from 70 to 140 MPa (10,000 to 20,000 psi). This high injection velocity ensures that the mold cavity is filled completely and uniformly before solidification.

Upon injection, the metal rapidly cools and solidifies within the water-cooled die. This rapid solidification, coupled with the applied pressure, minimizes shrinkage defects and enhances the part's dimensional stability. Ejection pins then push the solidified casting from the die. Post-casting, processes like trimming, deburring, and CNC machining are often applied to achieve the final required tolerances and surface finishes. For specialized components, heat treatment may be employed to further enhance mechanical properties. Our products adhere to stringent quality control, including ISO 9001 and ANSI standards, ensuring consistent performance and an extended service life in critical applications.

Key Technical Parameters for Pressure Casting

| Parameter | Typical Range (Aluminum Die Casting) | Impact on Product |

|---|---|---|

| Injection Pressure | 70 - 140 MPa (10,000 - 20,000 psi) | Reduces porosity, enhances density and mechanical properties. |

| Molten Metal Temperature | 650 - 750 °C (1200 - 1380 °F) | Affects fluidity, die erosion, and final microstructure. |

| Cycle Time | 10 - 90 seconds (part size dependent) | Influences production rate and cost-efficiency. |

| Dimensional Tolerance | ±0.05 mm to ±0.2 mm | Ensures precise fit and function, minimizes post-machining. |

| Surface Finish | Ra 0.8 - 3.2 µm | High aesthetic quality and reduced friction in applications. |

| Typical Wall Thickness | 1.5 mm - 6 mm | Achievable for lightweight yet strong designs. |

Applications and Advantages in Key Industries

Industry Applications of Pressure Castings

The versatility and high performance of components manufactured through pressure casting make them indispensable across a wide spectrum of industries. In the petrochemical sector, precision-engineered components like our Oem Die Casting Piston Fittings are crucial for maintaining system integrity and preventing leaks, directly contributing to operational safety and efficiency. Their inherent resistance to corrosion, especially when fabricated from specific aluminum alloys, ensures long-term reliability in harsh chemical environments. Similarly, the metallurgy industry relies on the dimensional accuracy and robustness of these castings for machinery parts that endure high temperatures and mechanical stresses.

For the water supply and drainage sectors, components requiring excellent sealing properties and resistance to water-borne corrosive elements benefit immensely from aluminium die casting products. Unlike aluminium gravity die casting, which typically offers slower production rates and coarser grain structures, high-pressure methods yield components with superior strength and finer finishes, critical for leak-proof and durable piping systems. Furthermore, the automotive, electronics, and aerospace industries frequently utilize imperial die casting techniques for lightweight, high-strength parts, where reducing overall weight without compromising structural integrity is paramount for fuel efficiency and performance.

Core Advantages for End Users

- Energy Efficiency: By enabling lighter-weight designs, especially in transportation, pressure casting contributes directly to reduced fuel consumption and lower carbon emissions. Our piston fittings, designed for optimal flow dynamics, can further enhance system efficiency.

- Corrosion Resistance: Utilizing specialized alloys and surface treatments, die cast components offer superior protection against environmental degradation, extending product lifespan significantly in corrosive environments.

- Dimensional Accuracy: The high-pressure injection ensures components are cast to near-net shape, reducing the need for costly secondary machining operations and ensuring precise fitment in complex assemblies.

- High Strength-to-Weight Ratio: Ideal for applications where weight reduction is critical, such as automotive or aerospace, providing robust performance without adding unnecessary mass.

- Complex Geometries: The ability to produce intricate designs with thin walls and complex internal features in a single casting, which would be challenging or impossible with other manufacturing methods.

Choosing the Right Partner: Customization and Assurance

Tailored Solutions and Our Commitment

Selecting a manufacturing partner for pressure casting components requires careful consideration of their technical capabilities, experience, and commitment to quality. Our expertise spans over two decades in delivering precision die-cast solutions, including the sophisticated Oem Die Casting Piston Fittings. We excel in offering customized solutions, collaborating closely with clients from concept design through to mass production. This includes material selection, mold design optimization, and post-processing, ensuring the final product meets exact specifications and performance requirements. Whether it's unique alloy compositions, specific surface finishes, or complex integrated features, our team leverages advanced simulation tools and engineering prowess to deliver optimal results.

Ensuring Trust and Reliability ( Focus)

- Authoritativeness & Expertise: With ISO 9001 and ISO/TS 16949 certifications, our manufacturing processes are rigorously controlled. We maintain a team of metallurgical engineers and CAD/CAM specialists, ensuring every project benefits from deep technical knowledge and extensive practical experience in pressure casting.

- Experience: Our portfolio includes successful partnerships with leading companies in the automotive, marine, and industrial equipment sectors. We have consistently provided components that withstand extreme operational demands, validated by extensive in-house and third-party testing.

- Trustworthiness: We offer a transparent delivery cycle, typically ranging from 4-6 weeks for tooling and initial samples, followed by efficient mass production schedules. All products come with a comprehensive quality assurance warranty, backed by dedicated customer support for any technical inquiries or after-sales service. Our commitment to client satisfaction is paramount.

Frequently Asked Questions (FAQ)

Common Inquiries Regarding Pressure Casting and Our Services

To further enhance transparency and address common concerns, we've compiled a list of frequently asked questions regarding pressure casting and our manufacturing capabilities.

- What materials can be used in your pressure casting process?

We primarily work with a range of aluminum alloys (e.g., A380, A356, ADC12), zinc alloys (e.g., Zamak 3, Zamak 5), and magnesium alloys. Our engineering team can assist in selecting the optimal material for your specific application and performance requirements. - What are the typical lead times for custom Oem Die Casting Piston Fittings?

Lead times for custom projects vary depending on complexity. Tooling and initial sample production typically take 4-6 weeks, with subsequent mass production runs having a lead time of 2-4 weeks, depending on order volume and current production queue. - How do you ensure the quality of your pressure cast products?

Our quality assurance process is multi-faceted, including material certification, in-process inspections, dimensional checks using CMMs (Coordinate Measuring Machines), X-ray inspection for internal defects, and comprehensive final inspections. We adhere strictly to ISO 9001 and industry-specific standards to guarantee product integrity. - Can you assist with design optimization for pressure casting?

Absolutely. Our engineering team provides Design for Manufacturability (DFM) analysis. We work closely with clients to optimize designs for the pressure casting process, ensuring cost-effectiveness, manufacturability, and superior performance of the final component. This includes recommendations on wall thickness, draft angles, and gating systems.

Authoritative References

The information presented herein is underpinned by established metallurgical principles and industry best practices. For further technical depth, please refer to the following authoritative sources:

- ASM Handbook, Volume 15: Casting. ASM International, 2008.

- Campbell, J. The Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann, 2011.

- Kalpakjian, S., & Schmid, S. R. Manufacturing Engineering and Technology. Pearson Education, 2014.

- Davis, J. R. (Ed.). Aluminum and Aluminum Alloys. ASM International, 1993.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering, CustomizationNewsAug.14,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.14,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery & Equipment Trading Co., Ltd.NewsAug.13,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Fluid Control&Custom SolutionsNewsAug.13,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Customizable SolutionsNewsAug.13,2025