Precision Machining Processes: Modern Manufacturing

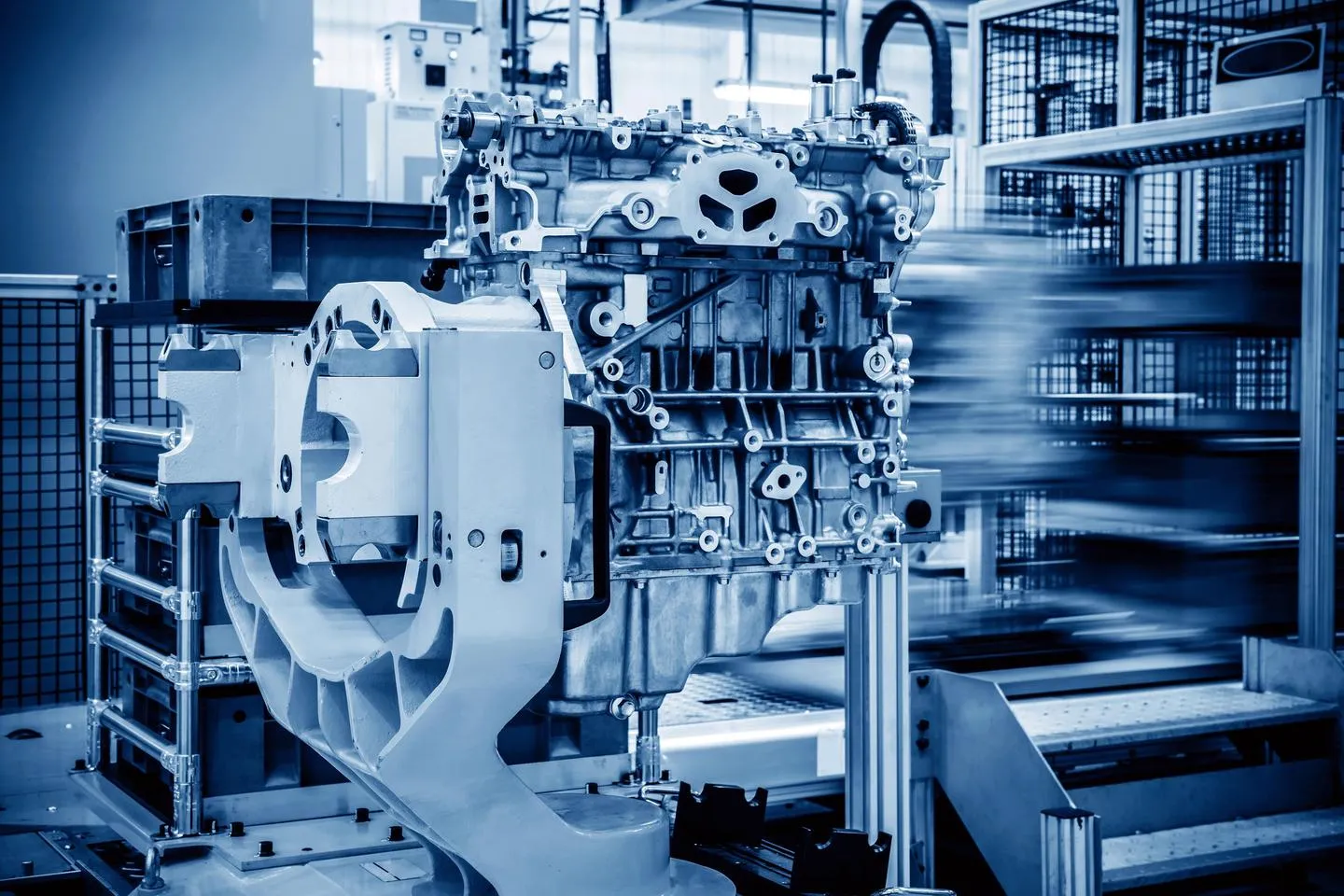

The manufacturing industry continues to evolve through innovative material removal technologies, with machining manufacturer capabilities driving precision and efficiency. Alongside machining design, machining process, additive machining, and machining types, these techniques enable the production of complex, high-tolerance components. This article explores their technical specifications, industrial applications, and answers key manufacturing questions.

Innovations in Machining Manufacturer Capabilities

Modern machining manufacturer facilities integrate multi-axis CNC systems with advanced automation for uninterrupted production. These operations utilize adaptive control technologies that automatically adjust cutting parameters based on real-time tool wear monitoring. The most sophisticated machining manufacturer operations now incorporate machine learning algorithms that optimize tool paths and predict maintenance needs before quality deviations occur. Automated inspection systems using laser scanning and vision technology verify dimensional accuracy, while robotic work handling ensures consistent throughput for high-volume production.

Critical Considerations in Machining Design

Effective machining design requires a comprehensive understanding of material behavior, tooling capabilities, and production workflows. Modern CAD/CAM systems play a crucial role in simulating cutting forces and thermal effects to prevent tool deflection and maintain dimensional accuracy throughout the manufacturing process. The strategic selection of datums and reference surfaces establishes a reliable foundation for precision machining operations, while optimized wall thicknesses help mitigate vibration issues that could compromise part quality. Proper allowances must be incorporated to accommodate secondary finishing operations, ensuring final components meet stringent specifications. Additionally, careful consideration of chip evacuation pathways becomes particularly important when machining deep cavity features, as efficient chip removal directly impacts tool life and surface finish quality. These fundamental machining design principles collectively enable manufacturers to achieve tight tolerances while optimizing production efficiency and reducing lead times.

Optimizing the Machining Process

The contemporary machining process has evolved significantly through technological advancements that enhance both precision and productivity. High-speed machining techniques now leverage advanced tool coatings and sophisticated coolant delivery systems to maintain optimal cutting conditions throughout extended production runs. Trochoidal milling strategies have emerged as an efficient method for material removal, reducing cutting forces while improving tool life. Intelligent tool condition monitoring systems provide real-time feedback on tool wear, enabling proactive maintenance before quality issues arise. Dynamic fixture technologies offer adaptive solutions that compensate for part variations, ensuring consistent positioning accuracy across production batches. Integrated metrology systems further enhance process control by providing in-process verification of critical dimensions, allowing for immediate adjustments when necessary. These innovations in the machining process enable manufacturers to successfully machine complex geometries from challenging materials while consistently achieving superior surface finishes that meet the most demanding industry standards. The combination of these advanced techniques represents a significant leap forward in machining capabilities, offering manufacturers unprecedented levels of control over the production environment.

Exploring Additive Machining Hybrid Techniques

Additive machining combines deposition technologies with subtractive processes to create components impossible through traditional methods. Advanced additive machining systems feature:Integrated powder bed fusion and milling stations,Hybrid manufacturing cells with automatic tool changers,Real-time thermal compensation for distortion control and Multi-material deposition capabilities.

These systems enable the production of complex internal cooling channels, functionally graded materials, and lightweight structural components with superior mechanical properties.

FAQs About Advanced Machining Manufacturing

What quality certifications distinguish leading machining manufacturer operations?

Top-tier machining manufacturer facilities maintain multiple industry certifications including ISO 9001 for quality management systems and AS9100 for aerospace applications. NADCAP accreditation is essential for special processes like chemical processing and nondestructive testing in critical components. Medical device manufacturers require ISO 13485 certification, while automotive suppliers typically need IATF 16949 compliance. These credentials demonstrate a machining manufacturer's commitment to maintaining rigorous process controls, traceability systems, and continuous improvement protocols across all production operations.

How does material selection impact machining design decisions?

Material characteristics profoundly influence machining design considerations throughout the development process. Hardness and machinability ratings determine appropriate cutting tool selections and parameter ranges. Thermal conductivity affects heat dissipation strategies and may require special coolant delivery systems. Material grain structure influences optimal cutting directions to achieve desired surface finishes. The machining design for aluminum differs significantly from titanium or hardened steels, requiring specific considerations for chip control, tool engagement, and vibration damping. Modern simulation software allows designers to predict machining behavior based on material properties, enabling optimized process plans before physical production begins.

What technological advancements have transformed modern machining process capabilities?

Contemporary machining process innovations include several groundbreaking developments. Machine tool builders now incorporate linear motor drives that eliminate mechanical backlash while achieving positioning accuracy within sub-micron ranges. Intelligent process monitoring systems analyze spindle power consumption, vibration patterns, and acoustic emissions to detect tool wear or potential collisions in real-time. Advanced CAM software generates optimized tool paths that minimize air cutting while maintaining constant chip loads. Some systems now feature augmented reality interfaces that overlay setup instructions and inspection criteria directly onto workpieces. These technological advancements collectively enable machining process operations to achieve unprecedented levels of precision, efficiency, and repeatability across production runs.

What are the primary advantages of additive machining compared to traditional methods?

Additive machining offers several distinct benefits that complement conventional manufacturing approaches. The technology enables production of complex internal geometries that would be impossible to machine through subtractive methods alone. Additive machining significantly reduces material waste compared to traditional machining, particularly for near-net-shape components. The process allows for localized material property control through precise deposition parameters, enabling functionally graded materials in single components. Modern additive machining systems reduce lead times by combining multiple manufacturing steps into a single automated workflow. These advantages make the technology particularly valuable for aerospace, medical, and energy applications where complex, lightweight components with optimized mechanical properties are required.

How do different machining types affect surface integrity and part performance?

The selection among various machining types significantly influences the metallurgical and functional characteristics of finished components. Conventional milling may induce work hardening in certain alloys, while grinding can create beneficial compressive surface stresses that improve fatigue life. Electrical discharge machining preserves material properties in hardened tool steels but may leave a recast layer requiring secondary finishing. Ultrasonic machining produces minimal thermal damage in brittle materials but has limitations in feature resolution. The machining types chosen for critical applications must balance surface finish requirements, dimensional tolerances, and subsurface material condition to ensure optimal component performance in service. Advanced metrology techniques like white light interferometry and X-ray diffraction help manufacturers verify these critical surface integrity parameters.

This technical examination demonstrates how machining manufacturer capabilities, machining design principles, machining process innovations, additive machining technologies, and machining types collectively advance modern manufacturing. These interconnected disciplines continue to push the boundaries of what's possible in precision component production across industries.

-

Why Choose OEM Spark Plugs for Optimal Engine PerformanceNewsJul.16,2025

-

Unlock the Power of Die CastingNewsJul.16,2025

-

The Power of Sand Casting for Your Manufacturing NeedsNewsJul.16,2025

-

The Excellence of Precision CastingsNewsJul.16,2025

-

Maximize Efficiency with High-Quality Stamping PartsNewsJul.16,2025

-

Enhance Your Manufacturing with Aluminium Die CastingsNewsJul.16,2025