Feb . 15, 2025 01:22

Back to list

precifine die and casting

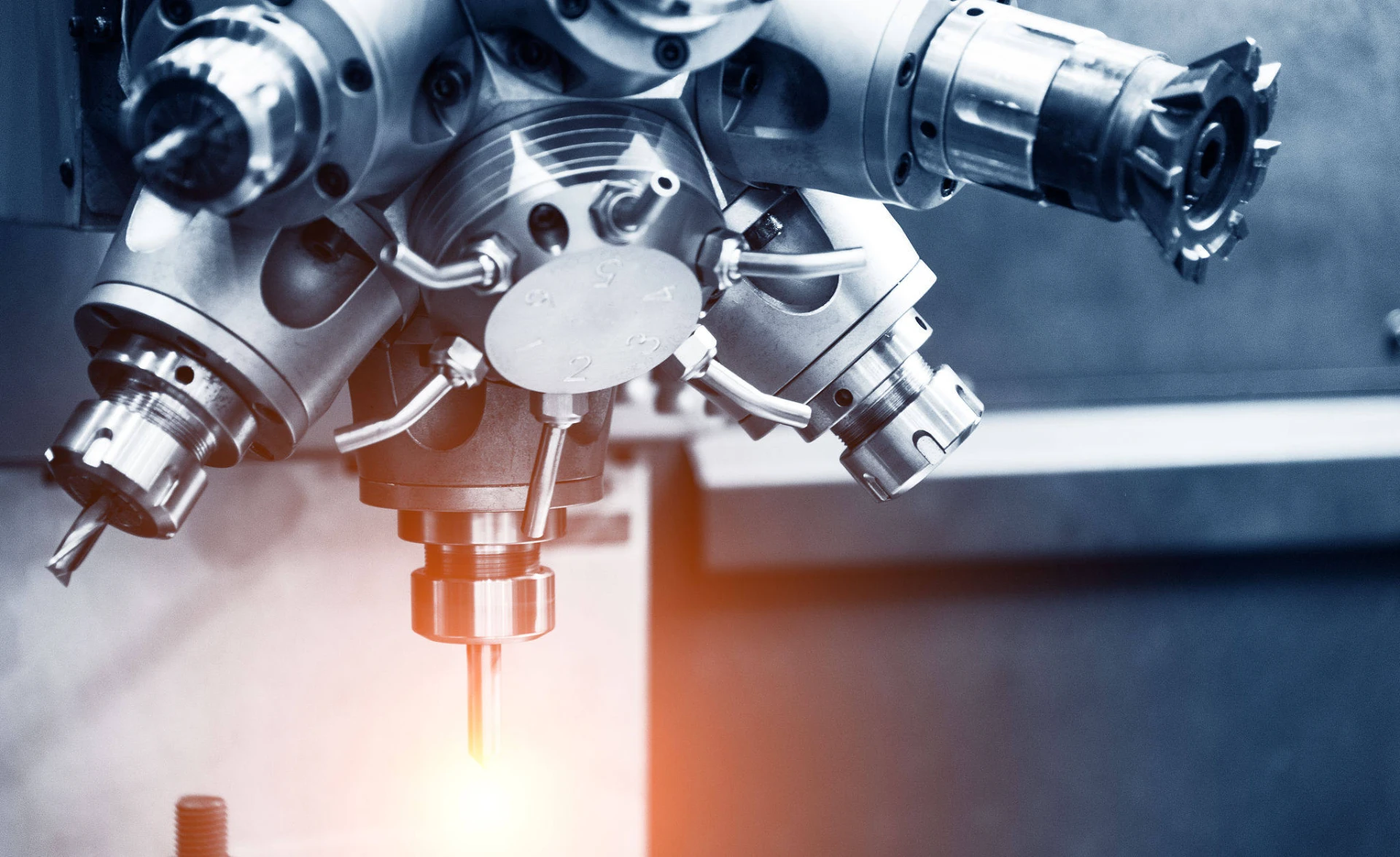

In the rapidly evolving world of manufacturing, precision and efficiency are paramount. The quest for superior die and casting processes has led industry experts to seek innovations that combine cutting-edge technology with unparalleled expertise. At the forefront of this pursuit lies precifine die and casting, a term synonymous with excellence in modern manufacturing.

Furthermore, environmental consciousness plays a pivotal role in modern die and casting processes. Eco-friendly practices, such as recycling excess material and using sustainable resources, not only reduce waste but also enhance the corporate responsibility profile of precifine die and casting enterprises. By reducing their carbon footprint and embracing sustainable methodologies, these companies demonstrate their commitment to protecting the environment, appealing to an increasingly eco-conscious market. Looking to the future, the evolution of precifine die and casting will be driven by continuous innovation and adaptation. The integration of Artificial Intelligence (AI) and machine learning in design and production processes promises to further enhance precision while minimizing waste. Predictive maintenance, powered by AI, can foresee equipment failures, reducing downtime and prolonging the lifespan of machinery. This evolution signifies a move towards a smarter, more efficient, and more sustainable industry standard. Additionally, as industries such as automotive, aerospace, and consumer electronics demand more complex and lightweight components, the role of precifine die and casting becomes even more critical. Companies that specialize in this field are actively engaged in research and development to push boundaries and offer customized solutions even for the most demanding applications. By investing in R&D, these companies not only stay ahead of technological advancements but also provide unmatched solutions that cater to specific customer needs, thus amplifying their market appeal. In conclusion, the realm of precifine die and casting is characterized by a commitment to precision, informed expertise, recognized authority, and unwavering trustworthiness. Through relentless innovation and adherence to quality, companies in this space are not just meeting the demands of modern manufacturing—they are setting new standards that shape the future of the industry. As they continue to evolve, their contributions will undoubtedly lead to new opportunities and advancements in the manufacturing landscape.

Furthermore, environmental consciousness plays a pivotal role in modern die and casting processes. Eco-friendly practices, such as recycling excess material and using sustainable resources, not only reduce waste but also enhance the corporate responsibility profile of precifine die and casting enterprises. By reducing their carbon footprint and embracing sustainable methodologies, these companies demonstrate their commitment to protecting the environment, appealing to an increasingly eco-conscious market. Looking to the future, the evolution of precifine die and casting will be driven by continuous innovation and adaptation. The integration of Artificial Intelligence (AI) and machine learning in design and production processes promises to further enhance precision while minimizing waste. Predictive maintenance, powered by AI, can foresee equipment failures, reducing downtime and prolonging the lifespan of machinery. This evolution signifies a move towards a smarter, more efficient, and more sustainable industry standard. Additionally, as industries such as automotive, aerospace, and consumer electronics demand more complex and lightweight components, the role of precifine die and casting becomes even more critical. Companies that specialize in this field are actively engaged in research and development to push boundaries and offer customized solutions even for the most demanding applications. By investing in R&D, these companies not only stay ahead of technological advancements but also provide unmatched solutions that cater to specific customer needs, thus amplifying their market appeal. In conclusion, the realm of precifine die and casting is characterized by a commitment to precision, informed expertise, recognized authority, and unwavering trustworthiness. Through relentless innovation and adherence to quality, companies in this space are not just meeting the demands of modern manufacturing—they are setting new standards that shape the future of the industry. As they continue to evolve, their contributions will undoubtedly lead to new opportunities and advancements in the manufacturing landscape.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES