Mar . 04, 2025 11:59

Back to list

Oem Round Hole Flange Bracket

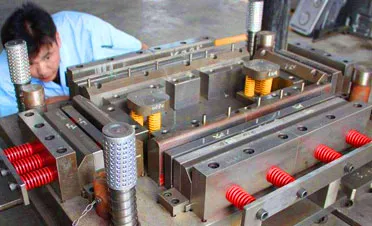

Part stamping, a specialized manufacturing process, is pivotal in creating high-quality, precision components used across various industries, including automotive, aerospace, electronics, and consumer goods. At its core, part stamping involves transforming flat sheet metal into specific shapes and sizes through pressing and die-cut processes. This expertise not only requires a deep understanding of materials but also integrates cutting-edge technology and rigid quality controls to produce parts that meet stringent industry standards.

Trustworthiness is built upon forming partnerships based on reliability, transparency, and customer satisfaction. We prioritize open communication with our clients, ensuring that their specific needs are understood and met with the utmost professionalism. Our dedicated team of engineers and quality control specialists works closely with clients throughout the development process, from initial design consultations to final production runs. This collaboration results in tailored solutions that consistently meet or exceed expectations in both quality and cost-effectiveness. Part stamping's critical role in manufacturing is evident through its ability to produce complex parts at high volumes while maintaining precision and efficiency. This process offers significant advantages such as minimal material waste, reduced production costs, and the capability to produce parts with intricate geometries that might be unachievable through other methods. Additionally, advancements in stamping technology have resulted in processes that are not only faster but also more environmentally sustainable, aligning with today's emphasis on green manufacturing practices. In conclusion, mastering the complexities of part stamping involves more than just technical proficiency; it requires a dedication to excellence, a commitment to innovation, and an unwavering focus on customer satisfaction. We stand as a beacon of authority and trust in the industry, delivering high-quality, reliable components that empower our clients to achieve their manufacturing goals. Whether the demand is for high-volume, standardized parts or bespoke, intricate designs, our part stamping capabilities are designed to meet the most demanding needs with precision and dependability.

Trustworthiness is built upon forming partnerships based on reliability, transparency, and customer satisfaction. We prioritize open communication with our clients, ensuring that their specific needs are understood and met with the utmost professionalism. Our dedicated team of engineers and quality control specialists works closely with clients throughout the development process, from initial design consultations to final production runs. This collaboration results in tailored solutions that consistently meet or exceed expectations in both quality and cost-effectiveness. Part stamping's critical role in manufacturing is evident through its ability to produce complex parts at high volumes while maintaining precision and efficiency. This process offers significant advantages such as minimal material waste, reduced production costs, and the capability to produce parts with intricate geometries that might be unachievable through other methods. Additionally, advancements in stamping technology have resulted in processes that are not only faster but also more environmentally sustainable, aligning with today's emphasis on green manufacturing practices. In conclusion, mastering the complexities of part stamping involves more than just technical proficiency; it requires a dedication to excellence, a commitment to innovation, and an unwavering focus on customer satisfaction. We stand as a beacon of authority and trust in the industry, delivering high-quality, reliable components that empower our clients to achieve their manufacturing goals. Whether the demand is for high-volume, standardized parts or bespoke, intricate designs, our part stamping capabilities are designed to meet the most demanding needs with precision and dependability.

Prev:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES