minda die casting

The Art and Science of Die Casting in Modern Manufacturing

Die casting is an innovative manufacturing process that has revolutionized the way parts are produced in various industries. This technique involves forcing molten metal into a mold (or die) under high pressure, allowing for the creation of complex shapes with precision. As businesses strive for efficiency, cost-effectiveness, and high-quality production, die casting emerges as an optimal solution.

At its core, die casting is a melding of art and science. The technical aspects involve understanding metallurgy, thermodynamics, and material properties. Different metals, such as aluminum, zinc, and magnesium, can be used in die casting, each offering distinct advantages. For instance, aluminum die castings are renowned for their lightweight and corrosion-resistant properties, making them ideal for automotive and aerospace applications.

The Art and Science of Die Casting in Modern Manufacturing

The importance of the die in die casting cannot be overstated. The die is a crucial component, often made from hard steel alloys, and it is designed to withstand the pressures of the casting process while maintaining precision. The die design impacts the quality of the final products, including factors such as wall thickness, surface finish, and overall geometry. Engineers spend significant time optimizing die designs to balance manufacturability with product performance.

minda die casting

One of the defining characteristics of die casting is its ability to produce parts with intricate details and tight tolerances. This quality makes die casting particularly appealing for industries such as automotive, where components like engine blocks, transmission cases, and other critical parts must meet stringent standards for performance and reliability. Additionally, die casting allows for the integration of multiple components into a single part, reducing assembly time and costs.

Sustainability is becoming increasingly important in the manufacturing sector, and die casting is no exception. Many manufacturers are adopting practices that minimize waste and energy consumption. For instance, recycling scrap metal generated during the die casting process not only conserves resources but also lowers production costs. Additionally, advancements in technology, such as the implementation of smart manufacturing practices, are enhancing the efficiency of die casting operations.

The die casting industry is also seeing the adoption of advanced technologies like 3D printing and simulation software. These tools facilitate the design and testing of die cast parts, allowing for quicker iteration and reduced time to market. By simulating the casting process before actual production, engineers can predict potential defects and make adjustments, ensuring high-quality outcomes.

In conclusion, die casting is a pivotal technique in modern manufacturing, effectively marrying artistry with engineering precision. Its ability to produce high-quality, intricate components in a cost-effective manner positions it as a favorite among manufacturers across various sectors. As the industry continues to evolve with advancements in technology and a focus on sustainability, die casting is set to play an even more significant role in the future of production.

-

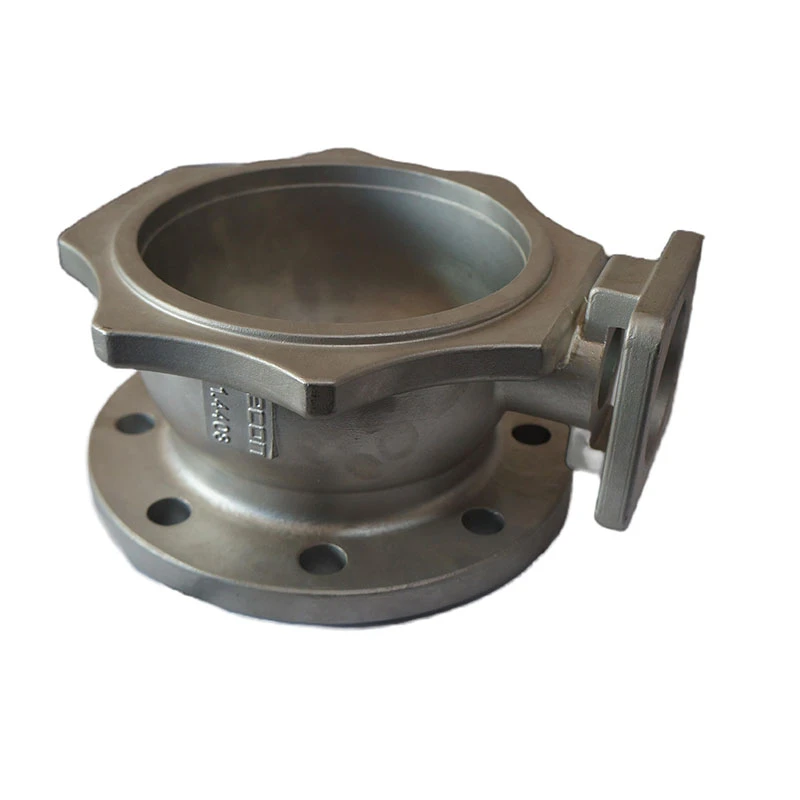

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025