Precision Metal Stamping Solutions for a Variety of Industrial Applications and Needs

Understanding Metal Stamping Services A Comprehensive Guide

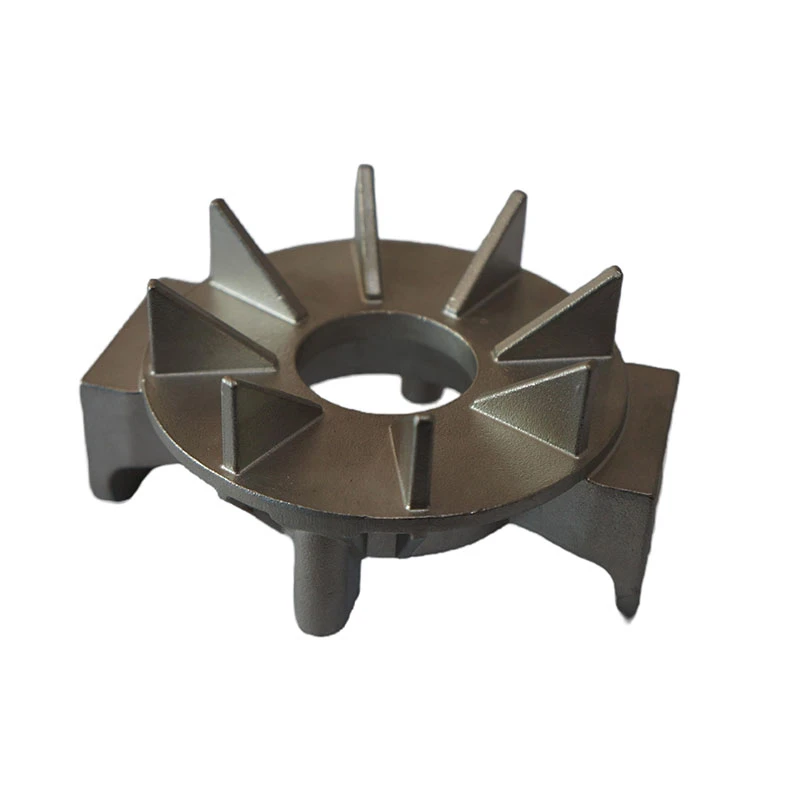

Metal stamping services play an integral role in various industries, from automotive and aerospace to electronics and appliances. These services involve the process of transforming flat metal sheets into intricate shapes through a combination of cutting, bending, and punching. The precision and efficiency of metal stamping make it a preferred manufacturing method for many companies looking to produce high-quality components at scale.

What is Metal Stamping?

Metal stamping is a manufacturing process that uses a die to shape metal sheets into desired forms. The process is accomplished by placing a metal sheet in a stamping press, which then applies force to the material through the die. This force causes the metal to deform into the specified shape. Metal stamping can be categorized into several techniques, such as deep drawing, embossing, piercing, blanking, and bending. Each technique serves a unique purpose and is selected based on the design and characteristics of the final product.

The Advantages of Metal Stamping

One of the primary advantages of metal stamping is its ability to produce precise parts consistently. The use of automotive-grade dies ensures that each piece manufactured conforms to strict dimensions and tolerances. This uniformity is essential for industries where quality and reliability are non-negotiable.

Moreover, metal stamping is capable of producing large volumes of parts quickly, making it a cost-effective option for mass production. The automation involved in stamping processes further increases production speed while minimizing labor costs.

Metal stamping also allows for the use of various materials, including stainless steel, aluminum, brass, and copper. This versatility in material selection enables manufacturers to choose the best option for their specific applications, balancing properties like strength, corrosion resistance, and weight.

Industries Utilizing Metal Stamping Services

Metal stamping services are utilized across a wide array of industries. The automotive sector, for instance, relies heavily on stamped parts for various components, such as brackets, support structures, and chassis components. Precision in these parts is crucial to ensure the safety and performance of vehicles.

metal stamping services

In the aerospace industry, metal stamping is used to create lightweight yet strong components critical for aircraft performance. The electronics industry also benefits from metal stamping as manufacturers produce parts for circuit boards, connectors, and housings with precise specifications.

Moreover, consumer goods such as appliances and furniture often incorporate stamped metal parts, demonstrating the method's broad applicability. Stamped components can be found in everything from washing machines to office equipment, emphasizing the importance of metal stamping in everyday products.

Choosing a Metal Stamping Service Provider

When selecting a metal stamping service provider, several factors need to be taken into consideration. First and foremost is the provider's experience and expertise in your industry. A company with a proven track record in manufacturing similar components can often provide insights and suggestions that enhance the design and functionality of your parts.

Quality assurance processes are also of paramount importance. Look for a provider that adheres to stringent quality control measures and is compliant with industry standards such as ISO 9001. This ensures that the components produced not only meet your specifications but will also perform reliably in their intended application.

Furthermore, consider the technology and equipment the provider utilizes. Advanced stamping presses and state-of-the-art technology can enhance precision and efficiency, leading to better outcomes in terms of both quality and timelines.

Finally, assess the provider's ability to offer customization. Many projects require unique solutions, and a flexible stamping service provider can adapt to your specific needs and provide tailored manufacturing solutions.

Conclusion

Metal stamping services are a cornerstone of modern manufacturing, providing the accuracy, efficiency, and versatility needed to produce high-quality components for various industries. Understanding the fundamentals of metal stamping and the advantages it offers can help businesses make informed decisions when selecting a manufacturing partner. With the right provider, companies can leverage metal stamping to improve their production processes and drive innovation in their respective fields. Whether you're in automotive, aerospace, or any other industry, the potential of metal stamping is vast and worth exploring.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025