Understanding the Fundamentals of Metal Stamping Techniques and Their Applications

Understanding Metal Stamping Processes

Metal stamping is a manufacturing process that uses a punch and die to form and shape metal materials into desired parts or products. This technique is widely utilized in various industries, including automotive, aerospace, electronics, and consumer goods due to its efficiency and precision. This article delves into the different types of metal stamping processes, their applications, and the advantages they offer.

Types of Metal Stamping Processes

1. Blanking Blanking is the initial step where a flat piece of metal is cut out from a larger sheet. The resulting cut-out piece is known as a blank, which can be further processed. This technique is foundational in metal stamping as it provides the basic shape needed for further operations.

2. Punching Similar to blanking, punching involves cutting holes or shapes out of the metal sheet. In this process, the remaining material (the slug) is often discarded or can be repurposed, depending on the application. Punching is commonly used to create holes for fasteners or other components in metal parts.

3. Bending Bending is a process that involves deforming the metal along a straight line. This can be achieved through various methods, including air bending, bottoming, and coining. Bending is essential for creating components that require angles or curves, such as brackets or frames.

4. Deep Drawing Deep drawing is employed to create more complex shapes by pulling a metal sheet into a die cavity. This process is widely used for making cylindrical or rounded components like beverage cans, automotive body parts, and kitchen sinks. Deep drawing requires careful control of material thickness and process parameters to ensure a high-quality finish without defects.

5. Forming This is a general term that includes various techniques used to create specific shapes in metalwork. It can involve bending, stretching, or compressing metal to achieve the desired form. Forming processes are critical in applications requiring close tolerances and complex geometries.

6. Embossing Embossing adds raised designs or patterns to the metal surface without cutting through it. This is commonly used in the decorative industries and can enhance the aesthetic appeal of finished products while also improving grip or reducing slip.

Applications of Metal Stamping

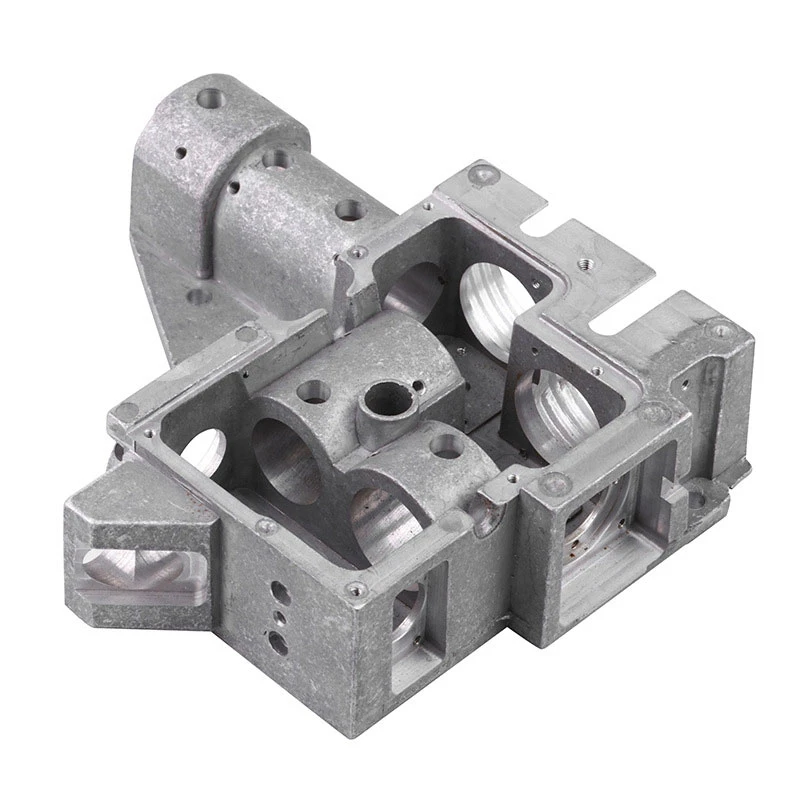

metal stamping processes

Metal stamping is used in a multitude of applications across different industries. For example, in the automotive sector, stamped metal parts are integral to constructing frames, body panels, and internal components. The aerospace industry also relies on precision-stamped parts for structural integrity and weight reduction. In electronics, stamped metal enclosures protect sensitive components, while consumer goods utilize metal stamping for items like cookware and appliances.

Advantages of Metal Stamping

Metal stamping offers several benefits that make it a preferred choice in manufacturing

- Cost-Effectiveness Once the initial tooling is created, metal stamping can produce large volumes of parts quickly, significantly increasing productivity and reducing unit costs.

- Precision This process provides tight tolerances, ensuring that parts fit together correctly and function as intended. Advanced tooling and machining techniques contribute to the high precision of stamped parts.

- Material Utilization Metal stamping is highly efficient in material usage, often generating minimal waste. Techniques such as progressive stamping allow for multiple operations in a single press cycle, maximizing the utilization of raw materials.

- Versatility Metal stamping can work with a variety of materials, including steel, aluminum, brass, and plastics, making it adaptable to different project requirements and specifications.

- Durability Stamped parts often exhibit increased strength and stability, ensuring long-lasting performance in their applications.

Conclusion

In conclusion, metal stamping is a vital manufacturing process that enhances efficiency in the production of metal components across various industries. Understanding the different types of stamping processes and their applications can help businesses optimize their manufacturing techniques. With its cost-effectiveness, precision, and versatility, metal stamping continues to play a significant role in modern manufacturing, helping to innovate and produce essential components for everyday use.

-

Pros & Cons of Sand Casting: Products & ApplicationsNewsAug.19,2025

-

Advanced Crawler Drilling Rig for Confined Spaces-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.18,2025

-

Crawler Drilling Rig- Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Pneumatic Power,Frame-Supported DesignNewsAug.18,2025

-

Precision OEM Valve Body Castings for Superior PerformanceNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun Machinery | Underground Drilling SolutionsNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun | Pneumatic Safety, Mining EfficiencyNewsAug.17,2025