Mar . 04, 2025 03:18

Back to list

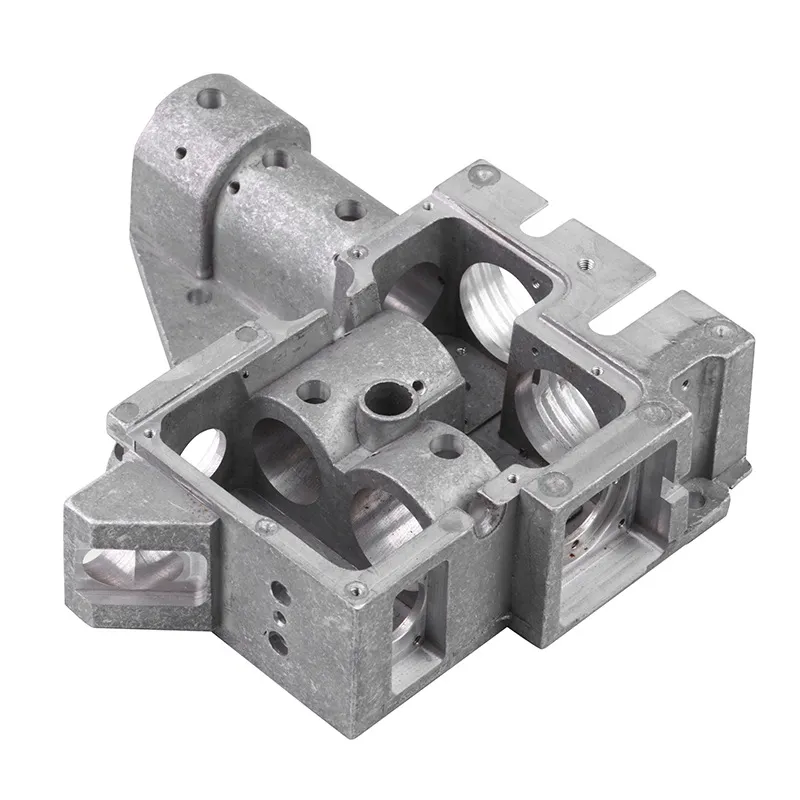

precision metal casting

Metal stamped parts are pivotal components across multiple industries, from automotive to electronics. The intricate process of metal stamping involves transforming flat metal sheets into specific shapes, utilizing techniques like blanking, piercing, and bending. The precision of metal stamped parts provides high repeatability, essential for mass production where consistency is paramount.

The evolving demand for custom solutions has led to the need for adaptable tooling solutions in metal stamping. Progressive dies, for instance, are equipped to perform multiple operations in a single stroke, improving production efficiency and reducing lead times. Additionally, there is a growing emphasis on sustainability in manufacturing practices. This has prompted a shift towards using eco-friendly materials and processes that minimize environmental impact. Recyclability of the metals used and the reduction of scrap through efficient stamping processes contribute to sustainability efforts within the industry. Metal stamping companies are further investing in training and skill development to maintain their competitive edge. Skilled technicians and engineers are continuously updated with the latest technologies and industry standards, ensuring they can operate sophisticated machinery and design innovative solutions that cater to diverse needs. This commitment to expertise underlines the authoritative prowess of leading manufacturers in delivering reliable and high-performance metal stamped parts. Trustworthiness in this industry is built through long-standing relationships with clients, characterized by consistent quality, on-time delivery, and responsive customer service. An open line of communication between manufacturers and clients ensures that requirements are accurately understood and met, fostering a sense of trust and reliability. Furthermore, compliance with international standards and certifications, such as ISO 9001 and IATF 16949, enhances credibility and assures clients of the quality and reliability of the products. In conclusion, metal stamped parts are integral to the manufacturing ecosystem, supported by advanced technology, expert material selection, stringent quality control, and adaptability to customizations. The industry continues to thrive by embracing technological innovations and sustainability, ensuring that quality and performance are never compromised. This dedication to precision and excellence cements the role of metal stamped parts as vital components in modern machinery and electronics, continuously driving progress and efficiency across various sectors.

The evolving demand for custom solutions has led to the need for adaptable tooling solutions in metal stamping. Progressive dies, for instance, are equipped to perform multiple operations in a single stroke, improving production efficiency and reducing lead times. Additionally, there is a growing emphasis on sustainability in manufacturing practices. This has prompted a shift towards using eco-friendly materials and processes that minimize environmental impact. Recyclability of the metals used and the reduction of scrap through efficient stamping processes contribute to sustainability efforts within the industry. Metal stamping companies are further investing in training and skill development to maintain their competitive edge. Skilled technicians and engineers are continuously updated with the latest technologies and industry standards, ensuring they can operate sophisticated machinery and design innovative solutions that cater to diverse needs. This commitment to expertise underlines the authoritative prowess of leading manufacturers in delivering reliable and high-performance metal stamped parts. Trustworthiness in this industry is built through long-standing relationships with clients, characterized by consistent quality, on-time delivery, and responsive customer service. An open line of communication between manufacturers and clients ensures that requirements are accurately understood and met, fostering a sense of trust and reliability. Furthermore, compliance with international standards and certifications, such as ISO 9001 and IATF 16949, enhances credibility and assures clients of the quality and reliability of the products. In conclusion, metal stamped parts are integral to the manufacturing ecosystem, supported by advanced technology, expert material selection, stringent quality control, and adaptability to customizations. The industry continues to thrive by embracing technological innovations and sustainability, ensuring that quality and performance are never compromised. This dedication to precision and excellence cements the role of metal stamped parts as vital components in modern machinery and electronics, continuously driving progress and efficiency across various sectors.

Latest news

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025

PRODUCTS CATEGORIES