machining design

Understanding Machining Design Key Concepts and Innovations

Machining design is a pivotal aspect of modern manufacturing, focusing on the creation and refinement of components used in various industries, including automotive, aerospace, and electronics. This discipline combines engineering principles, materials science, and cutting-edge technology to produce high-quality parts with precise specifications. As engineers and designers strive for efficiency, accuracy, and sustainability, the realm of machining design continues to evolve, incorporating innovative techniques and advanced technologies.

The Fundamentals of Machining Design

At the core of machining design lies the understanding of the machining process itself. Machining refers to the removal of material from a workpiece to achieve desired dimensions and surface finishes. This can be achieved through various methods, such as turning, milling, drilling, and grinding. Each method has its unique advantages and applications, making it imperative for designers to select the most appropriate technique based on the specific requirements of their projects.

One of the fundamental aspects of machining design is the selection of materials. Engineers must consider not only the mechanical properties of materials—such as strength, hardness, and ductility—but also their machinability. Materials that are easy to machine can significantly reduce production time and costs. Metals like aluminum and certain steels are often favored for their favorable machining characteristics, while harder materials like titanium may require specialized techniques to achieve the desired results.

Design for Manufacturability (DFM)

A critical principle in machining design is Design for Manufacturability (DFM). This approach emphasizes designing parts in a way that facilitates efficient manufacturing processes. By considering the capabilities and limitations of machining techniques early in the design phase, engineers can create components that are easier to produce with fewer complications. This may include optimizing geometries, minimizing tight tolerances, and selecting features that can be easily machined.

DFM not only helps reduce production costs but also enhances product quality. When parts are designed with manufacturability in mind, the likelihood of defects during machining decreases, leading to high-quality outputs that meet or exceed specifications. Moreover, DFM encourages collaboration between design and manufacturing teams, ensuring that both perspectives are considered throughout the development process.

machining design

Innovations in Machining Design

As technology advances, the field of machining design is witnessing remarkable innovations that enhance productivity, precision, and sustainability. Computer Numerical Control (CNC) machining has revolutionized the industry by allowing for automation and greater accuracy in the machining process. CNC machines can execute complex designs with minimal human intervention, significantly reducing the risk of errors and improving consistency in production.

Moreover, the integration of additive manufacturing—commonly known as 3D printing—into traditional machining processes is transforming how components are designed and produced. Engineers can now create intricate geometries that were previously impossible using conventional machining methods. This hybrid approach enables the production of lightweight structures, optimized for performance while minimizing material waste.

Sustainable practices are also gaining traction in machining design. As industries become increasingly aware of their environmental impact, there is a growing emphasis on designing processes that reduce energy consumption and waste. Techniques such as dry machining, which eliminates the need for cutting fluids, and the use of recycled materials in production are just a few examples of how the industry is striving to become more eco-friendly.

The Future of Machining Design

Looking ahead, the future of machining design appears promising, with ongoing advancements in technology and materials science. The rise of artificial intelligence (AI) and machine learning is expected to play a significant role in optimizing machining processes. These technologies can analyze vast amounts of data to identify patterns and recommend improvements, ultimately leading to enhanced efficiencies and reduced costs.

Additionally, as the demand for customized products increases, machining design will need to adapt to more flexible manufacturing systems capable of producing small batches of unique parts without sacrificing quality or time. This may involve further integration of automation and AI, enabling manufacturers to respond quickly to changing customer needs.

In conclusion, machining design is a dynamic field that continuously evolves with technological advancements and changing market demands. By embracing innovative practices and principles like DFM, the industry can produce high-quality components that meet the intricate requirements of modern applications. As we look to the future, the fusion of traditional machining techniques with cutting-edge technologies promises to drive further advancements and efficiencies, shaping the next generation of manufacturing.

-

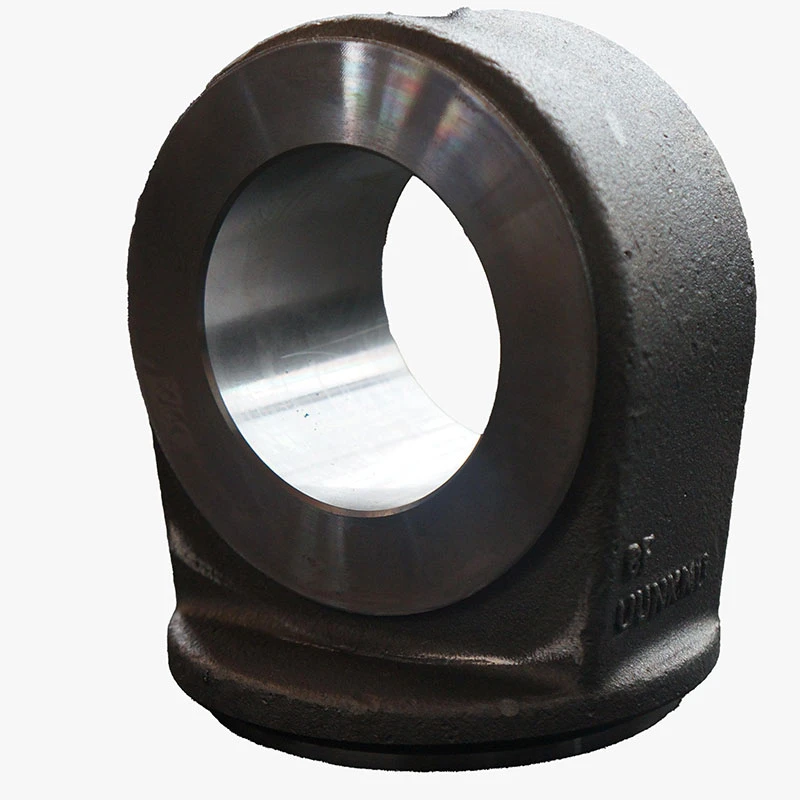

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025