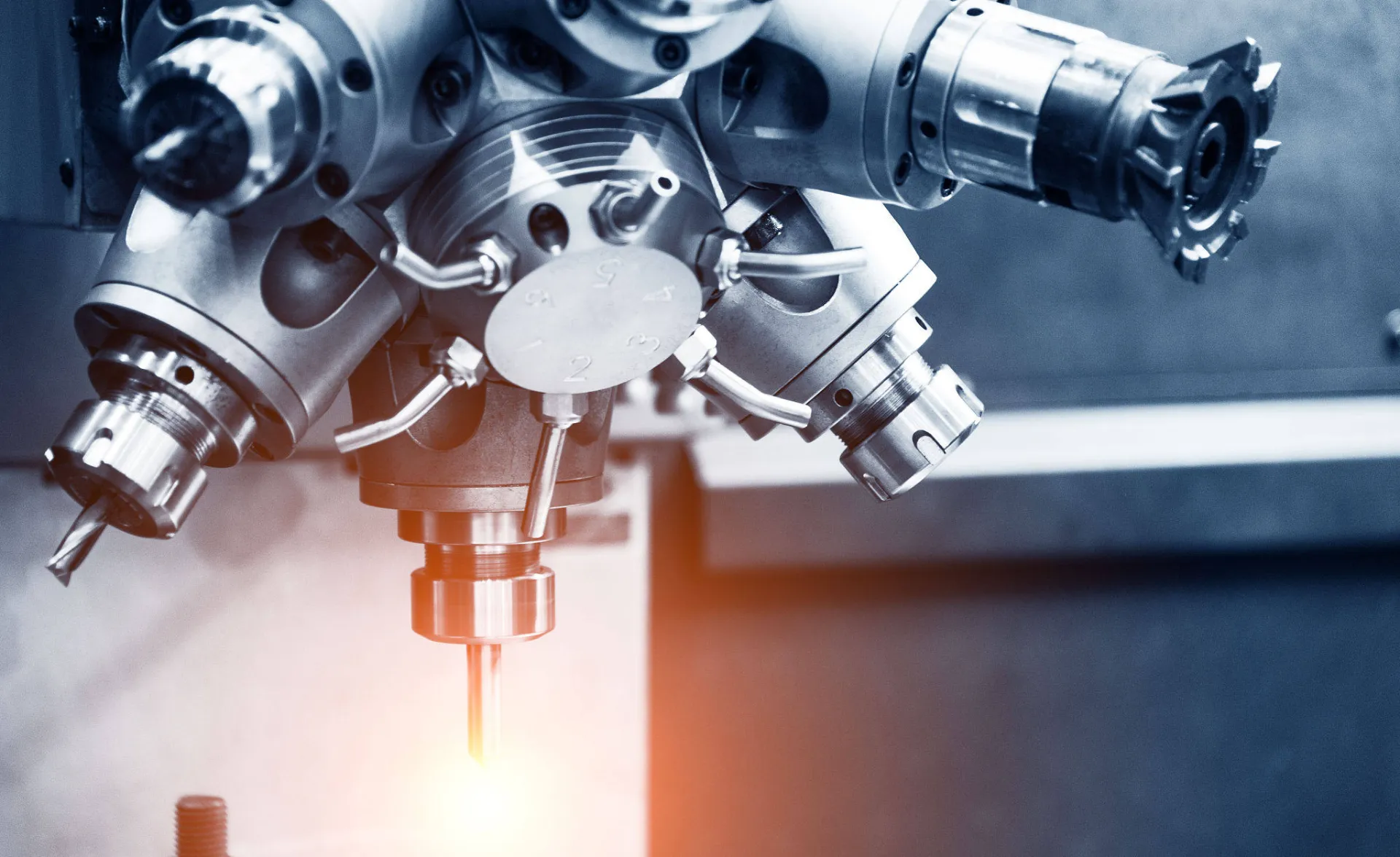

Machining Types for Precision Manufacturing

In the ever-evolving world of manufacturing, understanding various machining types is essential for creating precise, high-quality components. These processes are designed to shape, cut, and finish materials into desired forms, serving industries such as aerospace, automotive, and medical devices. From traditional turning and milling to advanced technologies like CNC machining and laser cutting, each type has unique applications and benefits.

The choice among machining types depends on factors like material properties, complexity of design, and production volume. For instance, CNC machining offers unparalleled precision, while abrasive jet machining excels in cutting intricate designs without thermal damage. By selecting the right machining types, manufacturers can optimize production efficiency and meet stringent quality standards.

The Role of Machining Manufacturers in High-Quality Production

Reliable machining manufacturers are the backbone of precision engineering, offering expertise and advanced technologies to produce intricate components. These manufacturers are equipped with state-of-the-art machinery and skilled professionals who ensure every part meets exacting specifications. Whether it’s prototyping or large-scale production, their ability to deliver consistent quality is unmatched.

Top machining manufacturers provide end-to-end solutions, from material selection to finishing. They excel in employing various machining types to address diverse industry needs, ensuring seamless integration into supply chains. Partnering with trusted machining manufacturers guarantees access to innovative techniques and a commitment to excellence, empowering businesses to achieve their production goals.

Analyzing Machining Price: Balancing Cost and Quality

For businesses, machining price is a critical factor in maintaining profitability without compromising product quality. The cost of machining services depends on variables such as material type, complexity of the design, and the machining types involved. While precision engineering can be expensive, strategic planning and efficient processes can help control costs.

Working with experienced machining manufacturers ensures a transparent pricing structure, allowing businesses to anticipate expenses and allocate budgets effectively. Techniques like bulk production, optimized tool paths, and efficient use of materials contribute to reducing machining price. By prioritizing value over cost, companies can secure reliable components while managing their bottom line.

Decoding the Abrasive Jet Machining Diagram for Enhanced Precision

The abrasive jet machining diagram serves as a blueprint for understanding the mechanics of this advanced machining process. Abrasive jet machining (AJM) utilizes a high-velocity stream of abrasive particles to cut or shape materials. This non-traditional method is ideal for working on brittle or heat-sensitive materials, as it eliminates the risk of thermal damage.

The abrasive jet machining diagram highlights the critical components of the system, including the nozzle, abrasive feeder, and compressed air source. Understanding this diagram is essential for optimizing performance and achieving precise cuts. Manufacturers rely on AJM for tasks requiring intricate detailing, demonstrating the versatility and efficiency of this innovative technology.

Why Businesses Choose Top Machining Manufacturers

Selecting the right machining manufacturers is crucial for ensuring high-quality production and reliable supply chains. These manufacturers excel in deploying various machining types, maintaining competitive machining price structures, and leveraging cutting-edge technologies like abrasive jet machining. Their ability to deliver tailored solutions positions them as indispensable partners for businesses across industries.

Top machining manufacturers focus on innovation, sustainability, and efficiency. By understanding processes such as the abrasive jet machining diagram, they continuously refine their operations to meet evolving industry demands. Choosing a trusted partner guarantees precision, cost savings, and long-term success in today’s competitive market.

This advertrial highlights the importance of understanding machining types, the expertise of machining manufacturers, the role of machining price, and the significance of the abrasive jet machining diagram. By exploring these elements, businesses can enhance production quality, reduce costs, and achieve operational excellence.

-

Types of Pressure Die CastingNewsMay.30,2025

-

Precision Casting Manufacturers for High-Quality Metal ComponentsNewsMay.30,2025

-

Key Steps in Aluminum Die Casting ManufacturingNewsMay.30,2025

-

How to Find Affordable Die Casting Components for SaleNewsMay.30,2025

-

General Topics on Casting & Die CastingNewsMay.30,2025

-

Discuss Leading Manufacturers SpecializingNewsMay.30,2025