Innovations in High Pressure Aluminum Die Casting for Enhanced Performance and Efficiency

High Pressure Aluminum Die Casting An Overview

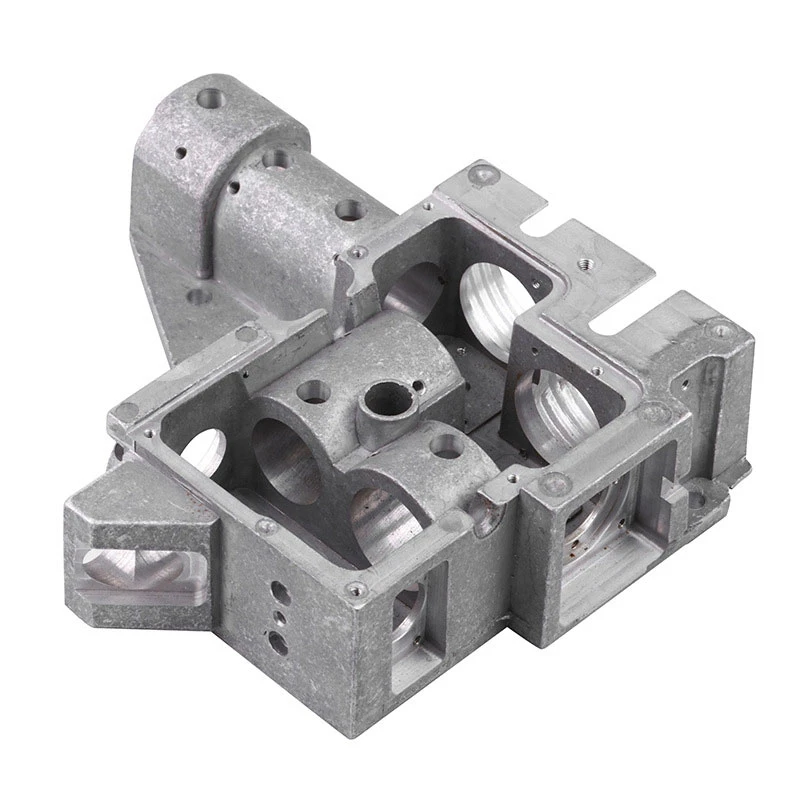

High pressure aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold cavity under high pressure. This method is widely used in various industries, including automotive, aerospace, electronics, and consumer goods, due to its ability to produce complex shapes with excellent dimensional accuracy and surface finish.

The process begins with the melting of aluminum alloy, which is typically done in a furnace. Once the aluminum reaches the desired temperature, it is injected into a die (the mold) at high speed and pressure. The pressure can range from 1,000 to 30,000 psi, depending on the specific requirements of the casting. The high pressure ensures that the molten aluminum fills the intricate details of the mold quickly and completely, minimizing defects such as air pockets or incomplete filling.

After the aluminum is injected into the mold, it solidifies rapidly due to the cool temperature of the mold. This quick solidification allows for fast cycle times, enabling manufacturers to produce high volumes of parts within a short period. Once the aluminum has cooled and solidified, the die is opened, and the cast part is removed. The entire process can be completed in seconds to minutes, making it highly efficient compared to other casting methods.

One of the key advantages of high pressure aluminum die casting is the excellent mechanical properties of the finished products. The rapid cooling during the casting process leads to a fine-grained structure, which enhances strength and durability. Additionally, aluminum is known for its lightweight characteristics, making it an ideal material for applications where reducing weight without sacrificing performance is crucial.

high pressure aluminum die casting

Another advantage is the ability to create complex geometries with intricate details and thin walls. High pressure die casting can produce parts with wall thicknesses as low as 1mm, allowing for more innovative designs and lightweight structures. This is particularly beneficial in the automotive industry, where manufacturers are constantly looking for ways to reduce vehicle weight to improve fuel efficiency and reduce emissions.

The surface finish achieved through high pressure die casting is also noteworthy. Parts produced by this method often have minimal surface defects and require little to no additional machining or finishing. This not only saves time and costs in production but also contributes to improved aesthetics, making the parts more appealing for consumer products.

However, there are challenges associated with high pressure aluminum die casting as well. The initial cost of die fabrication can be high, which may deter small-scale manufacturers. Additionally, the process requires precise control of temperature and pressure to avoid defects such as porosity and surface blemishes. Continuous monitoring and quality assurance measures are essential to maintain the desired standards of the final products.

In recent years, advancements in technology have further enhanced the capabilities of high pressure aluminum die casting. Innovations such as improved die materials, advanced mold designs, and automation in the casting process are helping manufacturers achieve even greater efficiency and precision.

In conclusion, high pressure aluminum die casting is a vital manufacturing process that offers numerous benefits, including rapid production, excellent mechanical properties, and the ability to create complex geometries. Its applications span a wide range of industries, making it an essential technique in modern manufacturing. As technology continues to advance, the potential for high pressure aluminum die casting is likely to expand, paving the way for even more innovative solutions in the future.

-

Pros & Cons of Sand Casting: Products & ApplicationsNewsAug.19,2025

-

Advanced Crawler Drilling Rig for Confined Spaces-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.18,2025

-

Crawler Drilling Rig- Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Pneumatic Power,Frame-Supported DesignNewsAug.18,2025

-

Precision OEM Valve Body Castings for Superior PerformanceNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun Machinery | Underground Drilling SolutionsNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun | Pneumatic Safety, Mining EfficiencyNewsAug.17,2025