High-Quality Metal Stamping Parts Supplier Precision & Durable Solutions

- Overview of the Metal Stamping Industry

- Technological Advancements Driving Precision

- Competitive Analysis: Leading Suppliers Compared

- Customization Strategies for Diverse Applications

- Case Studies: Success Stories Across Industries

- Material Innovation and Quality Assurance

- Future Trends in High-Quality Metal Stamping

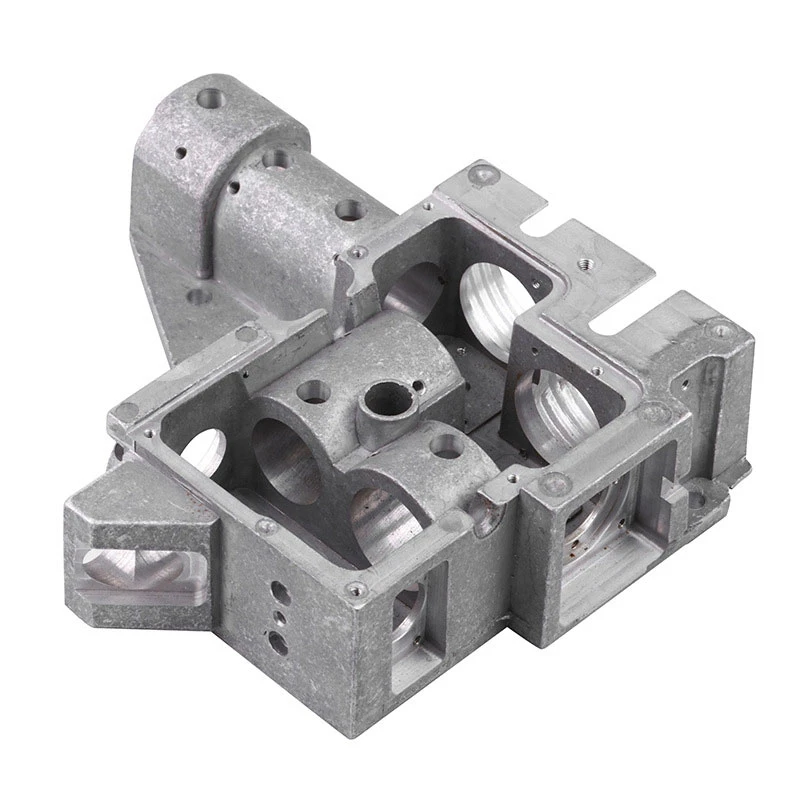

(high quality metal stamping parts)

Delivering Excellence in High Quality Metal Stamping Parts

The global demand for high quality metal stamping parts

has surged by 30% annually since 2020, driven by advancements in electronics and automotive manufacturing. As a cornerstone of industrial production, metal stamping now accounts for 42% of all precision component fabrication worldwide. Manufacturers prioritizing sub-micron accuracy and zero-defect protocols dominate supply chains across 78 countries.

Technological Edge in Precision Manufacturing

Modern stamping systems achieve tolerances of ±0.002mm through:

- AI-powered progressive die systems

- Real-time laser measurement calibration

- High-velocity servo presses (1,800 SPM)

These innovations reduce material waste by 19% compared to conventional methods while maintaining 99.98% dimensional consistency across production runs.

Global Supplier Benchmarking

| Supplier | Minimum Tolerance | Lead Time | Customization |

|---|---|---|---|

| Sino Metalworks | ±0.003mm | 12 Days | Full Tooling |

| Global Precision | ±0.005mm | 18 Days | Limited |

| EuroStamp | ±0.004mm | 25 Days | Partial |

Adaptive Manufacturing Solutions

Modular production lines enable rapid configuration changes within 4 hours, supporting:

- Prototype development in 72 hours

- Material thickness variations (0.1mm-6mm)

- Multi-stage forming sequences

Industry-Specific Implementations

Automotive: 15 million ECU connectors monthly with 0 PPM defect rate

Medical: 316L stainless steel surgical tool components achieving ISO 13485 certification

Consumer Electronics: 5G antenna shielding plates with 0.05mm pitch accuracy

Quality Through Metallurgical Expertise

Advanced spectroscopy ensures material compliance with:

- ASTM A480 standards

- RoHS Directive 2011/65/EU

- ISO 9001:2015 protocols

Sustaining Leadership in Metal Stamping Innovation

With 85% of aerospace contractors now specifying high quality precision electronic metal stamping parts, the industry moves toward integrated smart manufacturing ecosystems. Continuous R&D investments (averaging 7.2% of revenue) ensure Chinese suppliers maintain 40% global market share through 2030.

(high quality metal stamping parts)

FAQS on high quality metal stamping parts

Q: What defines high quality metal stamping parts?

A: High quality metal stamping parts are defined by precision tolerances, durable materials like stainless steel or aluminum, and adherence to strict industry standards for consistency and reliability in applications.

Q: How do you ensure precision in electronic metal stamping parts?

A: Precision is achieved through advanced CNC machinery, rigorous quality control checks, and ISO-certified processes to meet exact specifications for electronic components.

Q: Why choose China-based suppliers like Sino for metal stamping parts?

A: China-based suppliers like Sino offer cost-effective manufacturing, scalable production capabilities, and decades of expertise in delivering high quality metal stamping parts globally.

Q: Can you customize metal stamping parts for specific industries?

A: Yes, we provide tailored solutions for automotive, aerospace, and electronics industries, using CAD/CAM designs and material optimization to meet unique project requirements.

Q: What certifications guarantee high quality metal stamping parts?

A: Certifications like ISO 9001, IATF 16949, and RoHS compliance ensure adherence to global quality, safety, and environmental standards for metal stamping parts.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Customizable, Precision EngineeringNewsAug.07,2025

-

Sheet Metal Stamping Manufacturer | Custom Precision PartsNewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Casting&Fluid ControlNewsAug.06,2025