Top Suppliers for High-Quality Gravity Die Casting Solutions and Services

The Importance of Gravity Die Casting Suppliers in Manufacturing

Gravity die casting is a pivotal manufacturing process widely used across various industries for producing high-quality metal components. It involves pouring molten metal into a reusable mold or die, which allows for precise detailing and a superior surface finish. The success of gravity die casting heavily relies on the capability and expertise of suppliers who provide the necessary dies, machines, and support services. In this article, we will explore the role of gravity die casting suppliers and their significance in the manufacturing sector.

Understanding Gravity Die Casting

Gravity die casting, also known as permanent mold casting, is a process characterized by the use of gravity to fill the mold with molten metal. This technique is generally preferred for non-ferrous metals like aluminum, zinc, and magnesium due to its ability to create parts with excellent dimensional accuracy and surface finish. The process involves the following steps heating the die, pouring the molten metal, allowing it to cool and solidify, and finally removing the cast component.

The Role of Gravity Die Casting Suppliers

Suppliers in the gravity die casting industry play a crucial role that goes beyond merely providing metal casting services. They offer a variety of essential services and products, including

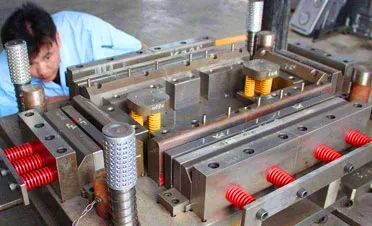

1. High-Quality Dies The quality of the die significantly impacts the overall quality of the finished product. Gravity die casting suppliers design and manufacture robust dies capable of sustaining repeated thermal cycles and pressures. Custom dies are often required to meet specific client needs, and experienced suppliers can provide tailored solutions.

2. Material Expertise Suppliers possess in-depth knowledge about different materials that can be used in die casting processes. Understanding the properties of metals like aluminum, zinc, and magnesium enables suppliers to recommend the right materials for specific applications, ensuring the desired strength, weight, and corrosion resistance.

gravity die casting supplier

3. Machine Provisioning Gravity die casting requires specialized machinery to operate efficiently. Suppliers may also offer die-casting machines, automation solutions, and maintenance services, ensuring that manufacturers have the right tools to optimize production processes. This can include anything from standalone units to fully integrated systems that enhance productivity.

4. Technical Support and Consultation Collaborating with experienced suppliers can provide manufacturers with vital technical support. Whether it’s determining the best machining practices, troubleshooting production issues, or optimizing the casting process, suppliers offer invaluable assistance that can lead to improved efficiencies and reduced costs.

5. Quality Control and Testing Reputable suppliers implement strict quality control measures to ensure that all produced components meet industry standards and client specifications. They often conduct tests such as dimensional inspections, mechanical property evaluations, and surface quality checks to ensure reliability and performance.

Industries Benefiting from Gravity Die Casting

The versatility of gravity die casting makes it applicable across numerous industries, including

- Automotive Components such as engine blocks, transmission cases, and structural parts benefit from the strength and lightweight nature of die-cast metals. - Aerospace Aerospace applications require high precision and reliability, which gravity die casting can provide for components like housings and brackets. - Consumer Electronics The casing for electronics often utilizes die-casting processes to achieve sleek designs with protection characteristics. - Medical Devices High-quality metal parts are essential in medical equipment, and gravity die casting ensures that these devices meet stringent safety and performance standards.

Conclusion

The role of gravity die casting suppliers is indispensable within the manufacturing landscape. Their expertise in die design, machining capabilities, and materials knowledge, combined with technical support and rigorous quality control, empowers manufacturers to produce high-quality components efficiently and economically. As industries continue to evolve, the contributions of gravity die casting suppliers will remain critical, driving innovation and excellence in manufacturing processes. By fostering strong partnerships with reliable suppliers, manufacturers can optimize their operations and ensure that they remain competitive in a global market.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025