fine casting sand

Fine Casting Sand An Essential Material in Metal Casting Processes

In the world of manufacturing, particularly in the metal casting industry, the use of sand as a mold material is well-established. Among the various types of sand used, fine casting sand stands out for its exceptional properties that make it an essential component in the production of high-quality castings. This article explores the characteristics, advantages, applications, and future trends of fine casting sand.

Characteristics of Fine Casting Sand

Fine casting sand is typically composed of silica and is characterized by its small particle size, which is crucial for creating detailed and intricate molds. The grain size usually falls within the range of 100 to 200 microns, providing a smooth texture that aids in achieving fine surface finishes on cast components. The other essential properties of fine casting sand include high thermal resistance, optimal permeability, and excellent refractoriness, allowing it to withstand the high temperatures associated with molten metal.

Another critical characteristic is the sand’s ability to retain its shape during the pouring of molten metal. This property is essential in producing accurate and high-precision metal parts. Moreover, fine casting sand can be re-used multiple times, making it a cost-effective choice for foundries.

Advantages of Fine Casting Sand

One of the most significant advantages of fine casting sand is its ability to produce intricate designs with smooth finishes. The fine grain structure allows for the reproduction of complex patterns, which is particularly important in industries that require high precision, such as aerospace and automotive manufacturing.

Additionally, the thermal properties of fine casting sand ensure that heat is evenly distributed during the pouring of molten metal, reducing the risk of defects like hot tearing or cold shuts

. The permeability of fine casting sand also plays a vital role in facilitating gas escape during the cooling process, thus minimizing the chances of casting defects.Economically, the ability to re-use fine casting sand multiple times lowers material costs for foundries. This sustainable aspect is increasingly important in today’s environmentally conscious manufacturing landscape, where reducing waste is a priority.

fine casting sand

Applications of Fine Casting Sand

Fine casting sand finds its application across various industries. In the automotive sector, it is commonly used for producing engine components and intricate parts like transmission housings. The aerospace industry also relies on fine casting sand for creating lightweight and complex components that require high strength and reliability.

Moreover, many artistic and decorative applications utilize fine casting sand. Sculptors and artisans often prefer this type of sand for creating detailed sculptures and decorative items that demand high aesthetic quality. The fine texture allows for producing smooth and detailed features, enhancing the overall appeal of the finished product.

Future Trends in Fine Casting Sand

As the manufacturing industry evolves, so does the technology and materials used in metal casting. Future trends are leaning towards more sustainable practices. Innovations in fine casting sand production, such as the incorporation of recycled materials and binders, are being explored to make the process more environmentally friendly.

Additionally, the advent of 3D printing technology is influencing the use of fine casting sand. 3D-printed molds made from fine casting sand offer quick prototyping capabilities and the potential to create designs that were previously unachievable with traditional methods. This combination of modern technology with traditional casting methods might significantly revolutionize production processes, enhancing efficiency and reducing lead times.

Furthermore, industry trends indicate an increasing demand for lightweight materials in manufacturing. Fine casting sand is poised to play a vital role in meeting these demands, as it allows for the production of components that are not only lightweight but also strong and durable.

Conclusion

Fine casting sand is a vital material in the metal casting industry, offering numerous advantages such as fine surface finishes, excellent thermal properties, and cost-effectiveness. Its applications span various sectors, from aerospace to automotive and artistic endeavors. As the industry moves towards sustainable practices and integrates new technologies, fine casting sand will likely continue to evolve, reinforcing its position as an essential material in modern manufacturing. The future holds exciting possibilities for fine casting sand, making it a topic of interest for both researchers and industry practitioners alike.

-

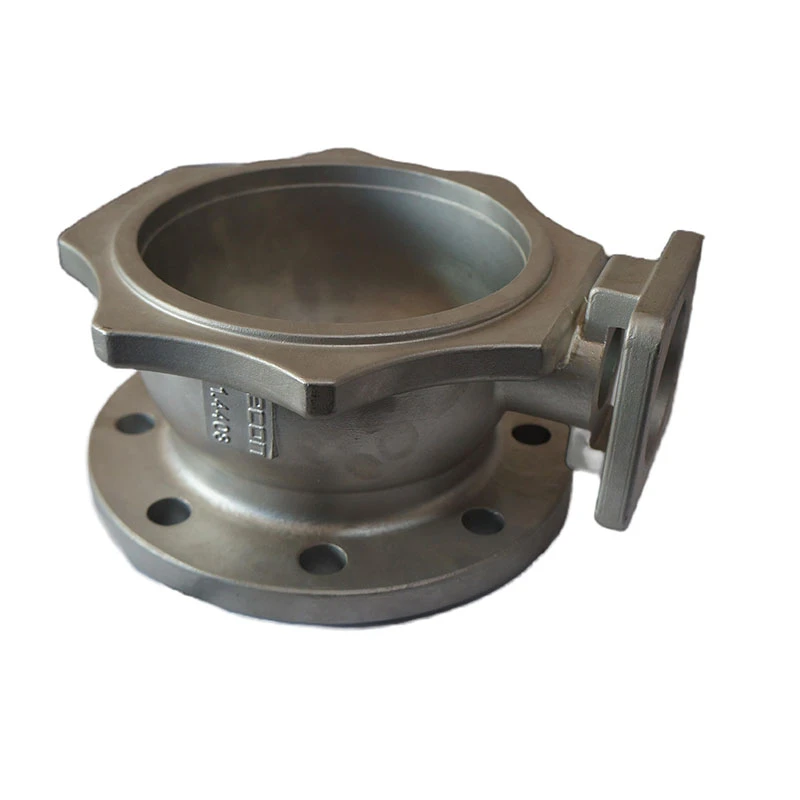

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025