Jan . 13, 2025 11:55

Back to list

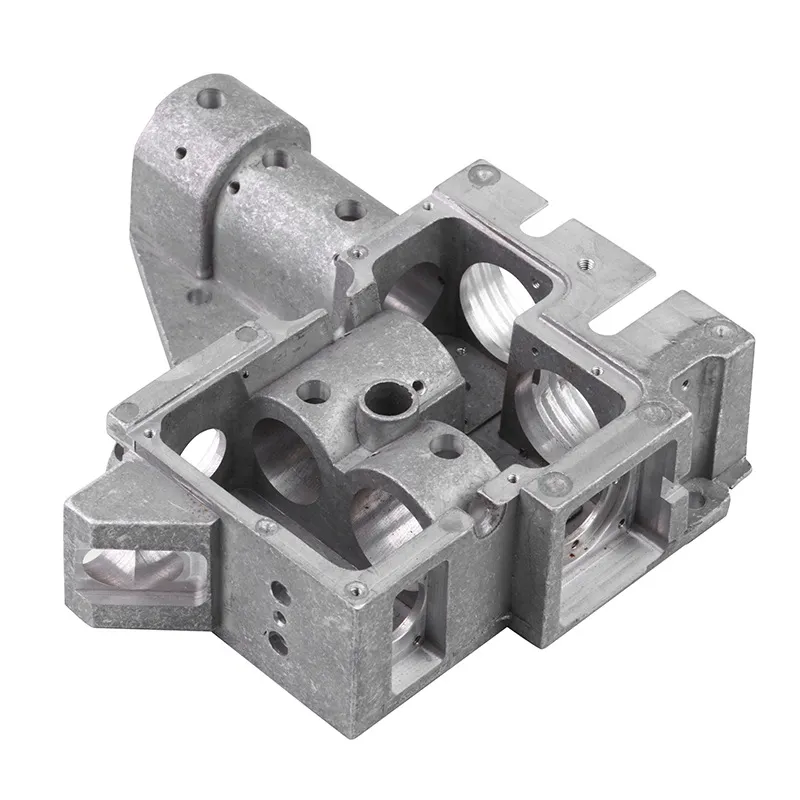

die cast pulleys

Die cast pulleys have become a crucial component in numerous industrial applications, offering superior performance and reliability. Their growing popularity is not just a result of technological advancement, but also because of their enhanced properties that make them an ideal choice for various settings.

The expertise involved in manufacturing die cast pulleys includes rigorous quality control processes and precise tooling. Top manufacturers invest in state-of-the-art CNC machines and employ skilled technicians who oversee each stage of the production. This commitment to quality ensures that each pulley meets stringent industry standards and performs consistently. Such expertise not only enhances the performance of the pulley but also guarantees longevity, which is a critical factor for reducing maintenance costs and downtime in operations. Authoritativeness in die cast pulley production comes from certification and adherence to international standards. Reputable manufacturers often adhere to ISO 90012015 for quality management systems. This standard confirms that the manufacturer consistently provides products that meet customer and regulatory requirements. Furthermore, many manufacturers develop strong relationships with their clients, providing expert advice on pulley selection and application, thereby positioning themselves as authorities in their field. Trustworthiness in the context of die cast pulleys is exhibited by manufacturers through transparency and after-sales support. A trustworthy company provides comprehensive product documentation, detailing material specifications, performance data, and care instructions. They also offer accessible customer service teams ready to troubleshoot and assist with any post-purchase inquiries. This relationship-building not only secures customer loyalty but also fosters trust in the quality and reliability of the products offered. The adoption of advanced technologies like CAD (Computer-Aided Design) and simulation software further demonstrates the industry's commitment to innovation. These technologies allow for the modeling and testing of pulleys before their physical production, ensuring flaws are minimized and the final product performs as desired from the outset. In summary, die cast pulleys are not merely components; they are engineered solutions designed to enhance performance across various industries. With their robust design and versatile application potential, they stand as a testament to the incredible possibilities of modern manufacturing techniques. When seeking reliable, efficient, and cost-effective pulley systems, die cast versions offer unmatched benefits, backed by the experience, expertise, authority, and trust that industry-leading manufacturers provide.

The expertise involved in manufacturing die cast pulleys includes rigorous quality control processes and precise tooling. Top manufacturers invest in state-of-the-art CNC machines and employ skilled technicians who oversee each stage of the production. This commitment to quality ensures that each pulley meets stringent industry standards and performs consistently. Such expertise not only enhances the performance of the pulley but also guarantees longevity, which is a critical factor for reducing maintenance costs and downtime in operations. Authoritativeness in die cast pulley production comes from certification and adherence to international standards. Reputable manufacturers often adhere to ISO 90012015 for quality management systems. This standard confirms that the manufacturer consistently provides products that meet customer and regulatory requirements. Furthermore, many manufacturers develop strong relationships with their clients, providing expert advice on pulley selection and application, thereby positioning themselves as authorities in their field. Trustworthiness in the context of die cast pulleys is exhibited by manufacturers through transparency and after-sales support. A trustworthy company provides comprehensive product documentation, detailing material specifications, performance data, and care instructions. They also offer accessible customer service teams ready to troubleshoot and assist with any post-purchase inquiries. This relationship-building not only secures customer loyalty but also fosters trust in the quality and reliability of the products offered. The adoption of advanced technologies like CAD (Computer-Aided Design) and simulation software further demonstrates the industry's commitment to innovation. These technologies allow for the modeling and testing of pulleys before their physical production, ensuring flaws are minimized and the final product performs as desired from the outset. In summary, die cast pulleys are not merely components; they are engineered solutions designed to enhance performance across various industries. With their robust design and versatile application potential, they stand as a testament to the incredible possibilities of modern manufacturing techniques. When seeking reliable, efficient, and cost-effective pulley systems, die cast versions offer unmatched benefits, backed by the experience, expertise, authority, and trust that industry-leading manufacturers provide.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES