Top Die Casting Manufacturers and Suppliers for Quality Metal Components

The Importance of Die Casting Companies in Modern Manufacturing

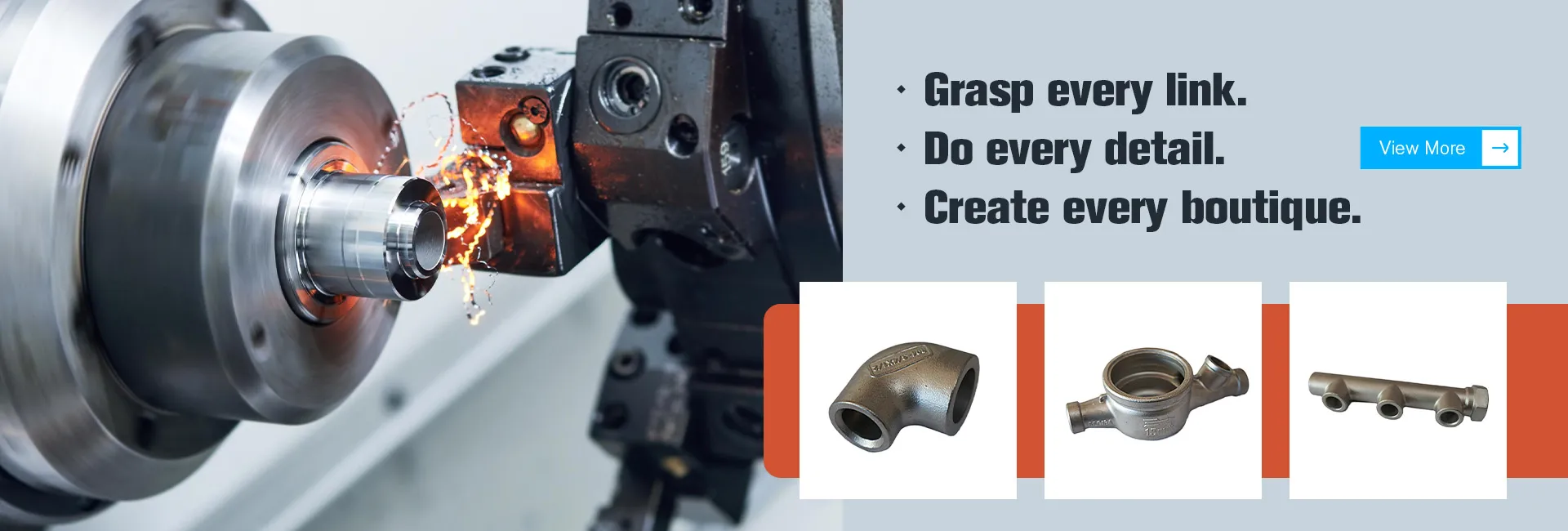

In the contemporary manufacturing landscape, the significance of die casting companies cannot be overstated. These specialized manufacturers play a crucial role in producing high-quality metal components that meet the stringent demands of various industries, including automotive, aerospace, electronics, and consumer goods. With the increasing complexity and volume of production required by modern industries, die casting has emerged as a preferred method for creating intricate metal parts with excellent precision and durability.

Die casting is a process that involves forcing molten metal under high pressure into a mold cavity. This technique is favored for its ability to produce complex shapes and tight tolerances consistently. The resulting products are often lightweight yet strong, making them ideal for applications where performance and reliability are paramount. Common materials used in die casting include aluminum, zinc, and magnesium, each chosen for their unique properties and suitability for different applications.

One of the defining features of a reputable die casting company is its commitment to quality and innovation. Leading manufacturers employ advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining to enhance precision and efficiency in their production processes. These technologies enable the creation of highly detailed molds and parts that can be replicated consistently, reducing waste and improving overall productivity. Quality control measures are integral to the operations of die casting companies. Rigorous testing ensures that the final products meet the required industry standards, thus providing customers with assurance regarding the performance and reliability of the components.

When selecting a die casting manufacturer, factor in their expertise and experience in the field. Established companies often have a track record of successfully serving various industries, which reflects their ability to adapt to different requirements and challenges. Furthermore, a die casting supplier with a diverse portfolio can offer customized solutions, tailoring products to fit specific needs. This flexibility is vital in today’s fast-paced market, where clients often need unique solutions that off-the-shelf products cannot provide.

die casting company manufacturer supplier

In addition to producing high-quality components, many die casting manufacturers are focusing on sustainability and environmentally friendly practices. The die casting process, when conducted responsibly, generates minimal waste and can be optimized for energy efficiency. Manufacturers are increasingly adopting recycling practices, using reclaimed materials, and implementing cleaner technologies to reduce their environmental footprint. This commitment not only meets regulatory standards but also appeals to eco-conscious clients and consumers.

Collaboration between die casting companies and their clients is another vital element in the manufacturing process. Effective communication helps manufacturers understand the specific needs of their customers, leading to better product design and enhanced performance. Furthermore, collaboration can lead to innovations in product development, as companies work together to explore new materials, designs, and applications.

The global reach of die casting companies is also noteworthy. Many manufacturers are now able to serve clients across borders, facilitating international trade and collaboration. This global presence allows them to source materials more efficiently, tap into diverse markets, and respond swiftly to changing demands in the manufacturing sector.

In conclusion, die casting companies are essential players in the manufacturing ecosystem, providing the expertise, technology, and innovative solutions needed to produce high-quality metal components. Their commitment to quality, sustainability, and collaboration positions them as valuable partners to businesses across various industries. As the demand for precision-engineered components grows, so too does the significance of die casting manufacturers, who continue to shape the future of manufacturing with their advanced methodologies and dedication to excellence.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025