cleaning die cast aluminium

Cleaning Die Cast Aluminium A Comprehensive Guide

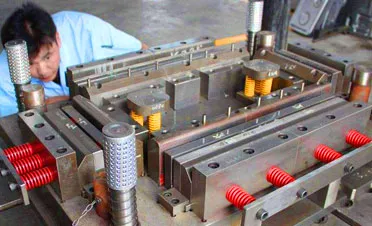

Die casting is a manufacturing process that involves injecting molten metal into a mold to produce complex shapes with high precision. Aluminium is one of the most commonly used metals in die casting due to its lightweight, strength, and corrosion resistance. However, once the production process is complete, cleaning die-cast aluminium parts is crucial for ensuring quality, aesthetic appeal, and functional performance. This article delves into effective cleaning methods, their importance, and best practices for maintaining die cast aluminium components.

The Importance of Cleaning Die Cast Aluminium

Cleaning die cast aluminium is not merely an aesthetic concern; it plays a vital role in the overall functionality and longevity of the component. The manufacturing process often leaves residues, such as oils, dust, and contaminants, on the surface of the parts. If these residues are not removed, they can interfere with subsequent processes such as painting, anodizing, or assembly, leading to poor adhesion, corrosion, or surface degradation.

Additionally, cleaning can help identify any production defects, such as pores or cracks, that could compromise the integrity of the component. A clean surface allows for better inspection and quality control, ensuring that only the highest quality products reach the market.

Cleaning Methods for Die Cast Aluminium

There are several effective methods for cleaning die cast aluminium, each varying in complexity, cost, and efficiency. Here are some of the most commonly used techniques

1. Mechanical Cleaning

Mechanical cleaning methods involve physically removing contaminants through scrubbing or abrasive techniques. This can be done manually with brushes or cloths or using machinery like vibratory finishers or sandblasters. While mechanical cleaning is effective in removing stubborn residues, it requires caution. Aggressive techniques may scratch or damage the aluminium surface, compromising its appearance and integrity.

2. Chemical Cleaning

Chemical cleaning is a popular option for removing oils, greases, and other contaminants. Solvents such as alkali cleaners and degreasers can effectively dissolve residues without damaging the aluminium surface. However, it is essential to choose a product specifically designed for aluminium to avoid unwanted reactions. After chemical cleaning, thorough rinsing is imperative to ensure no residues remain, as they can interfere with further treatments like plating or painting.

cleaning die cast aluminium

Ultrasonic cleaning utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution. When the bubbles collapse, they produce a powerful scrubbing action that can penetrate intricate surfaces and remove contaminants effectively. This method is particularly suitable for complex geometries or delicate parts that may be damaged by harsher cleaning methods. Ultrasonic cleaning is efficient and can yield high-quality results, making it an attractive option for many manufacturers.

4. High-Pressure Washing

For larger parts or those with extensive residues, high-pressure washing can be an efficient cleaning option. This method uses a jet of water under high pressure to remove dirt and contaminants. High-pressure washing is quick and can cover a large surface area. However, care must be taken to adjust the pressure appropriately to avoid damaging the aluminium surface.

Best Practices for Cleaning Die Cast Aluminium

To ensure successful cleaning and maintain the quality of die cast aluminium parts, here are some best practices to consider

- Assess the Contaminants Before choosing a cleaning method, identify the type and extent of the residues present on the aluminium surface. This assessment will guide the selection of the most appropriate cleaning technique.

- Test Cleaning Solutions When using chemical cleaners, always conduct a test on a small, inconspicuous area to ensure compatibility with the aluminium material. This will help avoid adverse reactions that could damage the surface.

- Protect the Surface After cleaning, it may be beneficial to apply a protective coating or finish to prevent future corrosion and maintain the aesthetic quality of the aluminium.

- Follow Safety Protocols When using chemical and mechanical cleaning methods, ensure proper personal protective equipment (PPE) is worn. Additionally, always adhere to safety guidelines and regulations to protect both workers and the environment.

- Regular Maintenance Establish a routine cleaning schedule to maintain the quality and integrity of die cast aluminium components. This proactive approach helps identify potential issues before they escalate.

Conclusion

Cleaning die cast aluminium is an essential step in the manufacturing process that contributes significantly to the overall quality and performance of the product. By understanding various cleaning methods and implementing best practices, manufacturers can ensure that their die cast aluminium components are free from contaminants, thereby enhancing their functionality and durability. As industries continue to innovate and demand higher standards, effective cleaning processes will remain a cornerstone of quality assurance in die casting.

-

Pros & Cons of Sand Casting: Products & ApplicationsNewsAug.19,2025

-

Advanced Crawler Drilling Rig for Confined Spaces-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.18,2025

-

Crawler Drilling Rig- Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Pneumatic Power,Frame-Supported DesignNewsAug.18,2025

-

Precision OEM Valve Body Castings for Superior PerformanceNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun Machinery | Underground Drilling SolutionsNewsAug.18,2025

-

Crawler Mounted Drill Rig - Baoding Hairun | Pneumatic Safety, Mining EfficiencyNewsAug.17,2025