Feb . 15, 2025 23:15

Back to list

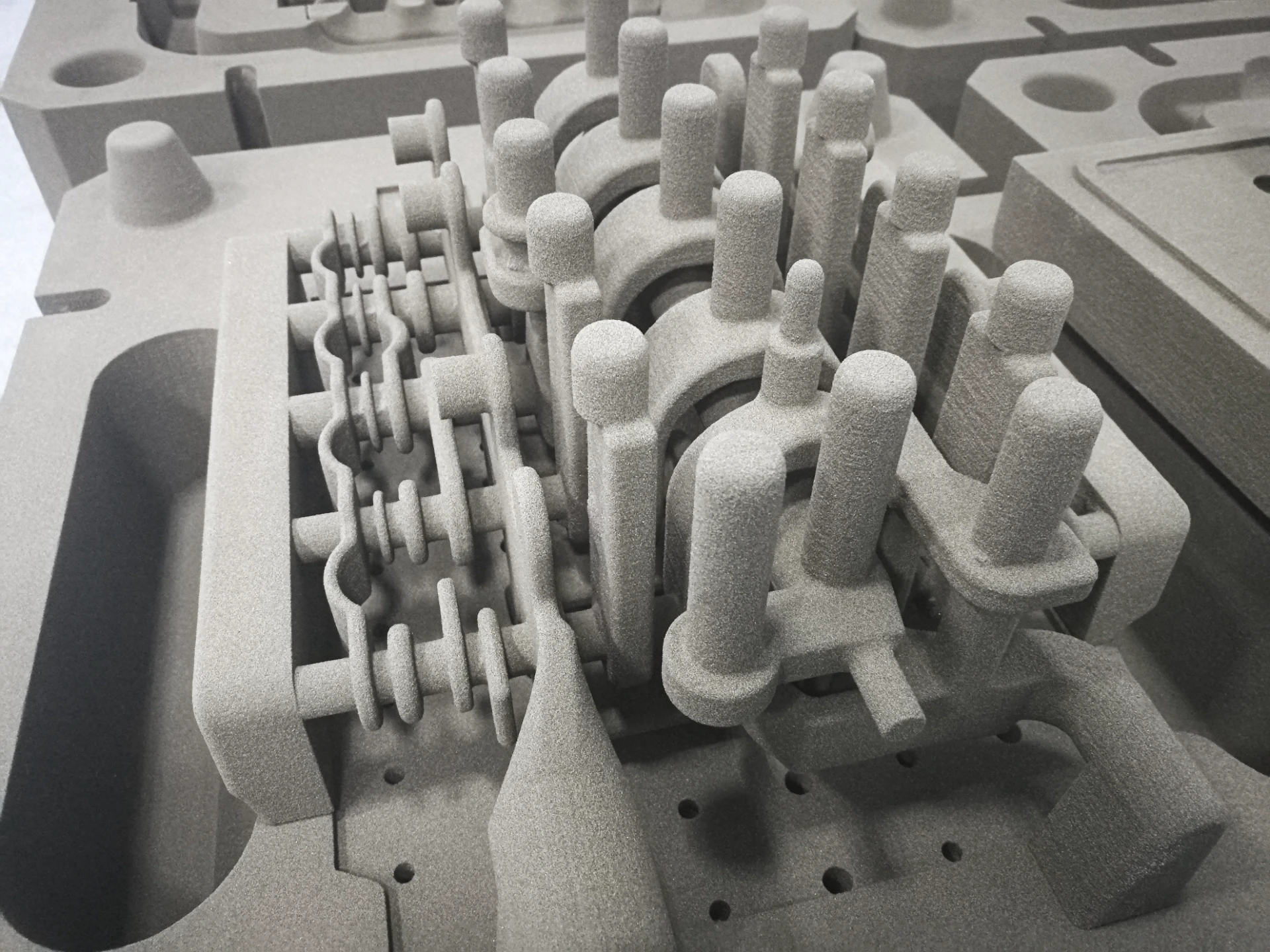

aluminium die casting products

Cleaning die-cast aluminum components requires a keen understanding of both the material properties and the cleaning processes that preserve the integrity of the finish. With the growing demand for high-quality, durable aluminum products, effective cleaning techniques are crucial to maintaining their lifecycle and functionality.

On a smaller scale, such as in household or SME environments, polishing compounds can also be used as a final step post-cleaning to protect the metal and enhance its shine. These compounds often contain fine abrasives that are gentle enough for regular use, providing a protective layer on the aluminum to reduce the likelihood of corrosion and oxidation. Environmentally-conscious cleaning solutions are gaining traction, emphasizing the importance of sustainability in the cleaning process. Biodegradable cleaning products that minimize ecological impact while maintaining efficacy are becoming increasingly popular. Choosing greener options helps to align with broader corporate sustainability goals and reassures customers who prioritize eco-friendly practices. Safety is another critical consideration during the cleaning process. Ensuring proper ventilation when using chemical solutions is vital to avoid inhaling potentially harmful fumes. Protective gear such as gloves and eyewear is recommended to safeguard against chemical exposure and enhance workforce wellbeing. By incorporating the right techniques and products, cleaning die-cast aluminum efficiently maintains the quality and longevity of the material. This not only meets industry standards but also enhances customer satisfaction with the final product. These practices underscore the significance of quality maintenance in the lifecycle of aluminum parts, reinforcing a reputation for reliability and excellence in production. Mastery in cleaning techniques reflects broader expertise and commitment to delivering superior die-cast aluminum products, benefiting both manufacturers and end-users in the long run.

On a smaller scale, such as in household or SME environments, polishing compounds can also be used as a final step post-cleaning to protect the metal and enhance its shine. These compounds often contain fine abrasives that are gentle enough for regular use, providing a protective layer on the aluminum to reduce the likelihood of corrosion and oxidation. Environmentally-conscious cleaning solutions are gaining traction, emphasizing the importance of sustainability in the cleaning process. Biodegradable cleaning products that minimize ecological impact while maintaining efficacy are becoming increasingly popular. Choosing greener options helps to align with broader corporate sustainability goals and reassures customers who prioritize eco-friendly practices. Safety is another critical consideration during the cleaning process. Ensuring proper ventilation when using chemical solutions is vital to avoid inhaling potentially harmful fumes. Protective gear such as gloves and eyewear is recommended to safeguard against chemical exposure and enhance workforce wellbeing. By incorporating the right techniques and products, cleaning die-cast aluminum efficiently maintains the quality and longevity of the material. This not only meets industry standards but also enhances customer satisfaction with the final product. These practices underscore the significance of quality maintenance in the lifecycle of aluminum parts, reinforcing a reputation for reliability and excellence in production. Mastery in cleaning techniques reflects broader expertise and commitment to delivering superior die-cast aluminum products, benefiting both manufacturers and end-users in the long run.

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES