Jan . 10, 2025 13:18

Back to list

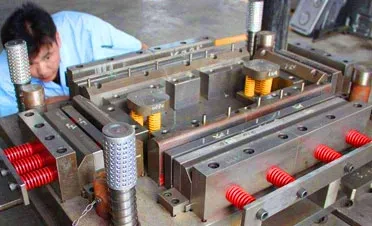

china precision die casting

Die casting parts offer a unique combination of precision, durability, and versatility, making them a cornerstone in the manufacturing industry. With decades of proven performance, die casting technology has evolved to meet the sophisticated demands of modern engineering. This advancement has solidified its place in industries ranging from automotive to consumer electronics.

In terms of trustworthiness, partnerships between suppliers and clients are built on consistent quality assurance and compliance with regulatory standards. Reliable die casting manufacturers implement rigorous quality control protocols. These include x-ray inspection, spectrometric analyses, and visual assessments to ensure defect-free production. Certifications such as ISO 9001 further underline a company's commitment to maintaining excellence. Reflecting on real-world experiences, companies utilizing die casting parts report substantial improvements in efficiency and product reliability. Automotive industries, for instance, rely on die cast components for engine parts, transmission housings, and intricate dashboard systems, enhancing overall vehicle performance and safety. Furthermore, firms specializing in consumer electronics appreciate the heat dissipation characteristics of die-cast heat sinks, crucial for maintaining optimal device temperature during operation. Despite these advantages, the expertise involved in die casting requires a tailored approach. Precision in mold design and controlled cooling rates must be meticulously managed to avoid defects such as porosity or warping. Continuous investment in skilled personnel and cutting-edge technology is necessary to remain competitive in the die casting industry. In conclusion, die casting parts encompass a blend of engineering excellence, proven reliability, and continual innovation. By aligning with experienced suppliers, businesses can harness the full potential of this manufacturing process, leading to enhanced product functionality and market success. For those seeking precision, durability, and performance, die casting emerges as an unparalleled choice in the manufacturing landscape. Through diligent attention to material selection, process execution, and quality assurance, companies not only meet but exceed demanding industry standards, securing their reputation as leaders in their respective fields.

In terms of trustworthiness, partnerships between suppliers and clients are built on consistent quality assurance and compliance with regulatory standards. Reliable die casting manufacturers implement rigorous quality control protocols. These include x-ray inspection, spectrometric analyses, and visual assessments to ensure defect-free production. Certifications such as ISO 9001 further underline a company's commitment to maintaining excellence. Reflecting on real-world experiences, companies utilizing die casting parts report substantial improvements in efficiency and product reliability. Automotive industries, for instance, rely on die cast components for engine parts, transmission housings, and intricate dashboard systems, enhancing overall vehicle performance and safety. Furthermore, firms specializing in consumer electronics appreciate the heat dissipation characteristics of die-cast heat sinks, crucial for maintaining optimal device temperature during operation. Despite these advantages, the expertise involved in die casting requires a tailored approach. Precision in mold design and controlled cooling rates must be meticulously managed to avoid defects such as porosity or warping. Continuous investment in skilled personnel and cutting-edge technology is necessary to remain competitive in the die casting industry. In conclusion, die casting parts encompass a blend of engineering excellence, proven reliability, and continual innovation. By aligning with experienced suppliers, businesses can harness the full potential of this manufacturing process, leading to enhanced product functionality and market success. For those seeking precision, durability, and performance, die casting emerges as an unparalleled choice in the manufacturing landscape. Through diligent attention to material selection, process execution, and quality assurance, companies not only meet but exceed demanding industry standards, securing their reputation as leaders in their respective fields.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES