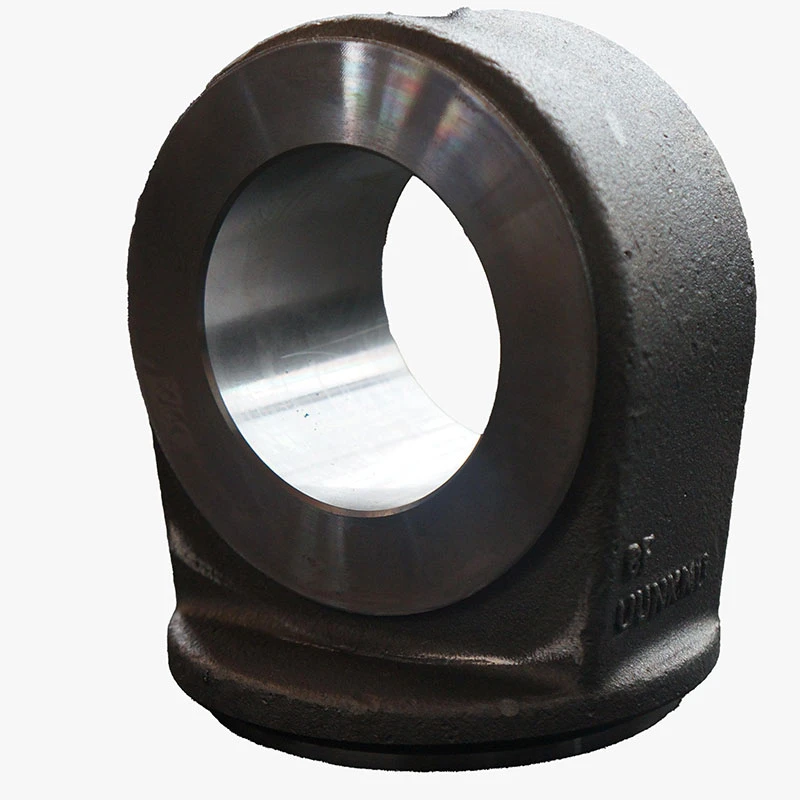

cast iron lapping plate

The Significance of Cast Iron Lapping Plates in Precision Engineering

In the realm of precision engineering, the choice of materials and tools can significantly affect the quality and accuracy of the final product. One such critical tool that has stood the test of time is the cast iron lapping plate. These plates have gained prominence in various manufacturing processes, particularly in achieving superior surface finishes and precise dimensions.

Understanding Lapping and Its Applications

Lapping is a machining process that involves the removal of material to achieve optimal surface finish and dimensional accuracy. This technique uses a combination of an abrasive slurry and a lapping plate to polish workpieces to a fine finish. The process is commonly employed in industries such as aerospace, automotive, and optical manufacturing, where the precision is crucial for component performance and safety.

Lapping plates serve as the foundation for this process, and among the various materials available, cast iron is widely regarded as the most effective choice. The dense and rigid nature of cast iron offers unique properties that contribute to the overall efficacy of lapping.

Advantages of Cast Iron Lapping Plates

1. Durability Cast iron is renowned for its robustness and can withstand the rigors of the lapping process. The inherent strength of the material ensures that it lasts longer than alternatives, reducing the need for frequent replacements and maintenance.

2. Stability The stability of cast iron lapping plates is a crucial factor in precision engineering. Cast iron does not warp or flex under the pressure of lapping, which is essential for maintaining uniformity in the finishing process.

3. Self-Repairing One of the unique features of cast iron is its ability to self-repair through a process known as skimming. When the surface of a cast iron lapping plate becomes worn, it can be resurfaced to restore its flatness, ensuring ongoing accuracy without the need for complete replacement.

cast iron lapping plate

4. Heat Resistance Cast iron can withstand higher temperatures compared to other materials, which is particularly beneficial during prolonged lapping processes. This heat resistance helps to prevent distortion and maintains the integrity of the workpieces being finished.

5. Cost-Effectiveness While initial investment in cast iron lapping plates may be higher than that of other materials, their long lifespan and durability make them cost-effective in the long run. The reduced frequency of replacements, coupled with the maintenance savings, can lead to significant cost advantages for manufacturers.

The Manufacturing Process of Cast Iron Lapping Plates

The creation of cast iron lapping plates involves various stages, including melting, molding, and machining. The process begins by melting cast iron in a furnace and pouring it into molds to form the desired plate shape. After solidification, these rough plates undergo precision machining to achieve flatness and surface finish acceptable for lapping processes.

Post-machining, the surface of the lapping plates is often ground to a fine finish, ensuring that they can hold the abrasive materials used during lapping efficiently. Surface textures and patterns may also be applied to enhance the material removal capabilities during lapping.

Conclusion

The utilization of cast iron lapping plates in precision engineering cannot be overstated. As manufacturing requirements continue to evolve, the need for precise machining techniques has never been greater. Cast iron lapping plates provide a stable, durable, and cost-effective solution for achieving the fine surface finishes and exact dimensions that modern applications demand.

As industries strive to enhance quality and optimize production, the role of cast iron lapping plates will likely continue to grow, serving as indispensable tools in the arsenal of precision engineering. Whether in aerospace, automotive, or optical sectors, the enduring benefits of these lapping plates will remain a cornerstone in the journey toward manufacturing excellence.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025