casting sand suppliers

Understanding the Importance of Casting Sand Suppliers in the Foundry Industry

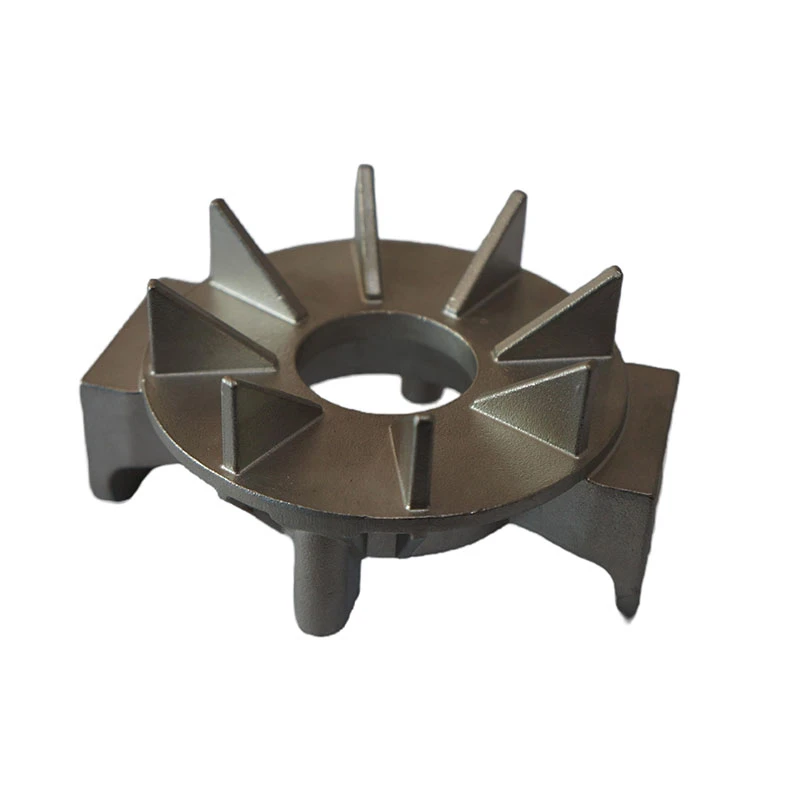

In the world of metal casting, the quality of the final product hinges significantly on the materials and processes employed during production. One of the most crucial raw materials used in casting is sand. The sand used in foundries is not just ordinary sand; it must possess specific characteristics to ensure the integrity of the casting process. This is where casting sand suppliers play an essential role in the foundry industry.

Casting sand, also known as foundry sand, serves as a mold material where molten metal is poured. The most commonly used type is silica sand, but variations such as olivine sand and zircon sand are also utilized depending on the requirements of the casting project. The effectiveness of foundry sand is evaluated based on its grain size, shape, and thermal stability, which impact the outcome of the casting. Thus, sourcing high-quality sand becomes imperative.

The Role of Casting Sand Suppliers

The primary function of casting sand suppliers is to deliver a product that meets the specific needs of the foundry industry. Suppliers must understand the nuances of different sand types and their applications. For example, fine grained sands provide excellent surface finishes, while coarse grained sands might be preferable for large, thick-walled castings. Furthermore, their knowledge of sand treatment techniques, including reclamation processes, enables them to offer tailored solutions to their customers.

Quality assurance is paramount; suppliers should be committed to providing consistent and reliable materials. This involves testing the sand for impurities, moisture content, and grain distribution to ensure that it meets industry standards. Suppliers often work closely with foundries to understand their requirements and develop a consistent supply chain that can respond to the fluctuating demands of production schedules.

Advantages of Working with Reliable Suppliers

casting sand suppliers

When foundries collaborate with reputable casting sand suppliers, several advantages emerge. First, the quality of the castings produced improves, leading to fewer defects and a higher yield. This efficiency ultimately reduces costs, as less material is wasted and rework is minimized. Second, a good supplier provides technical support and recommendations based on their expertise in sand applications. This can be invaluable, especially for foundries experimenting with new materials or techniques.

Moreover, an established supplier typically has a network of resources and partnerships that can benefit their clients. They may offer additional services such as on-site evaluations, custom sand blends, or logistical support. By leveraging these resources, foundries can enhance their operational efficiencies and focus on their core competencies.

Environmental Considerations

As the foundry industry makes cautious strides towards sustainability, casting sand suppliers are also advancing towards eco-friendly practices. The reusability of casting sand is one area where suppliers can make a significant impact. Implementing sand reclamation systems can help foundries minimize waste and lower the environmental footprint associated with sand disposal. Suppliers that prioritize sustainability help their clients comply with environmental regulations and promote a greener casting process.

Conclusion

In conclusion, the role of casting sand suppliers in the foundry industry cannot be overstated. These suppliers are not only responsible for the provision of high-quality sand, but they also bring valuable knowledge and support to the table. Collaborating with a reliable supplier can lead to improved casting quality, greater efficiencies, and a commitment to sustainable practices. As the demand for superior castings continues to rise, casting sand suppliers will undoubtedly remain a critical component in the success of foundries worldwide. Investing time in building a strong relationship with these suppliers will be a strategic advantage that can propel a foundry towards success in an increasingly competitive market.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025