Feb . 05, 2025 01:31

Back to list

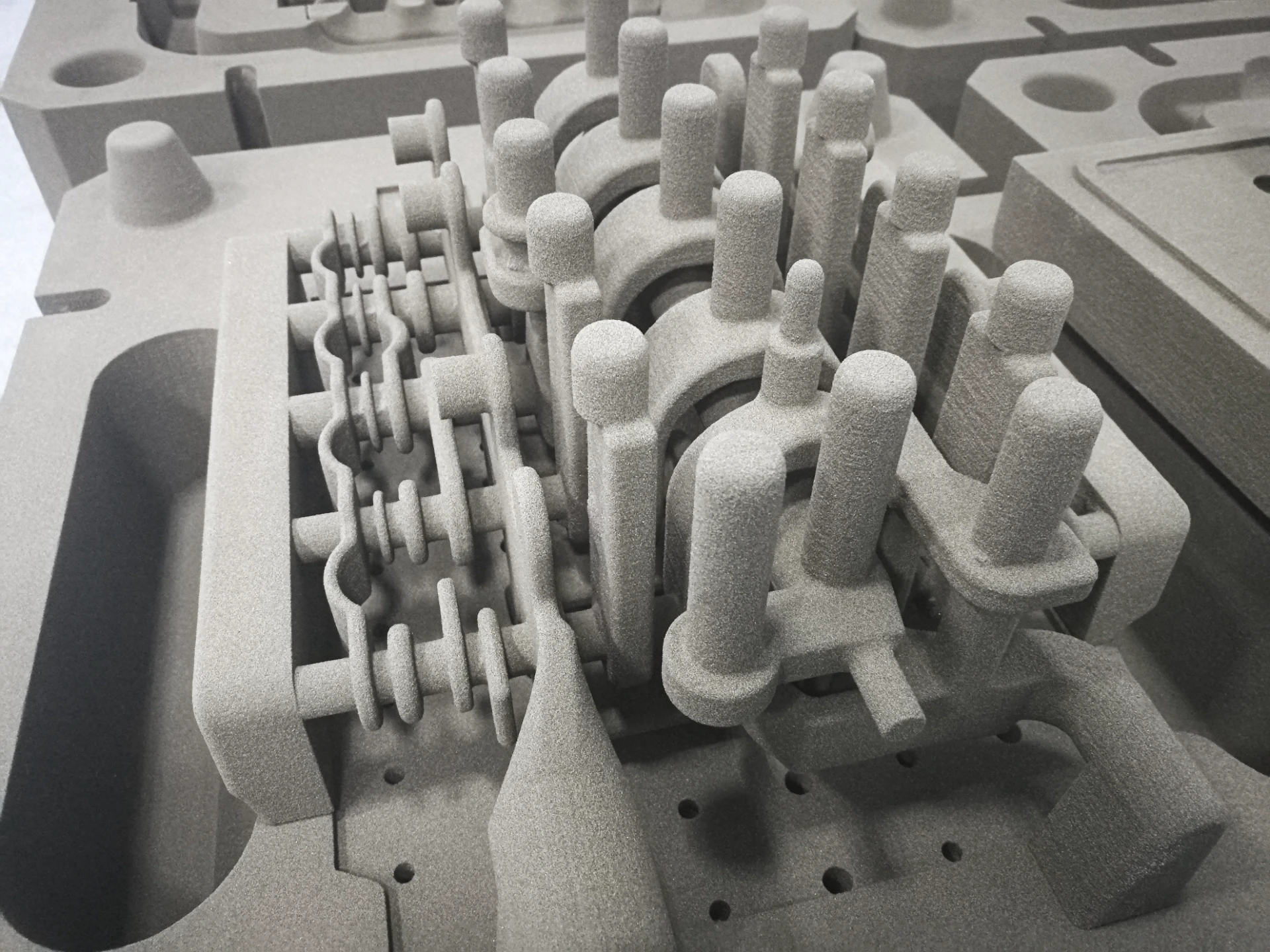

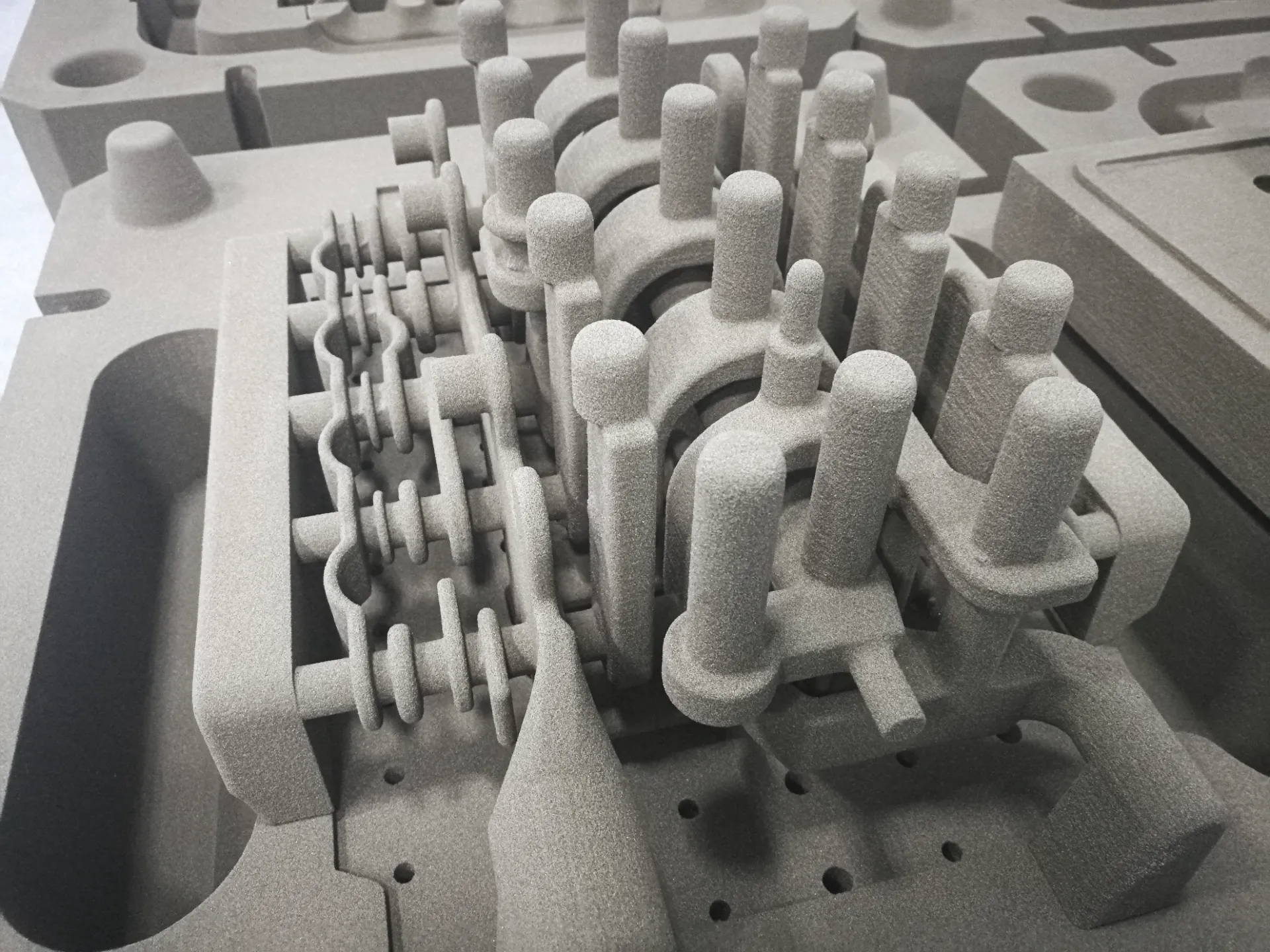

casting sand

Casting sand serves as the pivotal resource in the foundry industry, contributing to the creation of intricate metal shapes with remarkable precision. The unique properties of casting sand, primarily its ability to withstand high temperatures while maintaining shape, make it indispensable for metal casting processes such as sand casting, a method praised for its versatility and cost-effectiveness.

Trustworthiness in selecting suppliers or professionals dealing with casting sand is paramount. Reliable suppliers provide comprehensive material data sheets and quality certifications, ensuring that the sand meets all necessary industry standards. This transparency builds trust with clients seeking to uphold stringent quality controls in their manufacturing processes. Additionally, collaborating with trusted industry partners enables foundries to stay abreast of innovations in sand technology and sustainable practices. For those delving into the business of foundry, understanding the nuances of casting sand not only enhances operational efficiency but also positions the business to deliver superior quality products. Training programs and workshops focusing on the handling and optimization of casting sand are integral components that raise the skill level of workers, ensuring they are equipped to contribute effectively to production goals. In conclusion, casting sand stands as a cornerstone of the metal casting industry, demonstrating unparalleled expertise, authority, and trustworthiness. Its unique properties, coupled with the ability to adapt and evolve with technological advances, ensure its continued relevance. By engaging with casting sand through a lens of innovation and sustainability, foundries can secure their competitive edge, offering products that meet the highest standards of precision and quality.

Trustworthiness in selecting suppliers or professionals dealing with casting sand is paramount. Reliable suppliers provide comprehensive material data sheets and quality certifications, ensuring that the sand meets all necessary industry standards. This transparency builds trust with clients seeking to uphold stringent quality controls in their manufacturing processes. Additionally, collaborating with trusted industry partners enables foundries to stay abreast of innovations in sand technology and sustainable practices. For those delving into the business of foundry, understanding the nuances of casting sand not only enhances operational efficiency but also positions the business to deliver superior quality products. Training programs and workshops focusing on the handling and optimization of casting sand are integral components that raise the skill level of workers, ensuring they are equipped to contribute effectively to production goals. In conclusion, casting sand stands as a cornerstone of the metal casting industry, demonstrating unparalleled expertise, authority, and trustworthiness. Its unique properties, coupled with the ability to adapt and evolve with technological advances, ensure its continued relevance. By engaging with casting sand through a lens of innovation and sustainability, foundries can secure their competitive edge, offering products that meet the highest standards of precision and quality.

Prev:

Next:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES