Automotive Component Production Through Innovative Stamping Techniques

The Evolution and Importance of Auto Stamping Parts in the Automotive Industry

The automotive industry is a dynamic landscape that has continuously evolved over the years, driven by technological advancements and the ever-increasing demand for efficient production processes. One of the integral processes within this industry is auto stamping, which plays a crucial role in the manufacturing of various parts that contribute to the structural integrity and functionality of vehicles. This article delves into the significance of auto stamping parts, its technological advancements, and its impact on the automotive industry.

Understanding Auto Stamping

Auto stamping is a manufacturing process that involves shaping and cutting metal sheets into specific designs and forms that are essential for automotive production. This process is accomplished using stamping presses, which exert immense pressure to mold the metal into various parts, such as body panels, chassis components, and brackets. The use of metal sheets allows for lightweight construction without compromising strength, making it an ideal choice for modern vehicles.

Key Advantages of Auto Stamping

1. Efficiency and Speed The auto stamping process is highly efficient, enabling manufacturers to produce a large number of parts in a short period. With the ability to create complex shapes and designs quickly, stamping helps streamline the production line and reduce lead times.

2. Cost-Effectiveness The economies of scale associated with auto stamping make it a cost-effective solution for mass production. Once the initial setup and tooling are completed, the ongoing costs per unit decrease significantly, benefiting manufacturers eager to optimize their budgets.

3. Material Conservation Advanced auto stamping techniques, such as progressive stamping, allow for the optimal utilization of raw materials. This reduces waste and enhances overall sustainability within the production process.

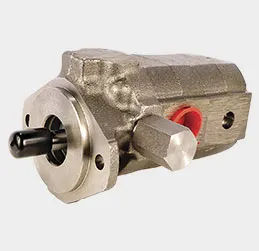

auto stamping parts

4. High Precision and Quality Modern stamping presses are equipped with state-of-the-art technology that ensures high precision in producing parts. This precision leads to improved quality and consistency, minimizing the need for extensive post-production adjustments.

Technological Advancements in Auto Stamping

Over the years, auto stamping has witnessed significant technological advancements that have further enhanced its productivity and capabilities. Computer numerical control (CNC) technology, for instance, allows for greater automation in the stamping process. Robotic systems facilitate the handling of heavy metal sheets, reducing human labor and increasing safety.

Additionally, innovations in materials, such as the development of high-strength steel and aluminum alloys, have improved the performance of stamped parts. These advanced materials provide better durability and a reduced weight, which is essential for meeting modern fuel efficiency standards and enhancing overall vehicle performance.

The Role of Auto Stamping in Sustainable Practices

As environmental concerns grow, the automotive industry is increasingly focusing on sustainable practices. Auto stamping contributes to these efforts through resource-efficient manufacturing methods and the development of lightweight vehicle components that improve fuel efficiency. By embracing eco-friendly materials and processes, manufacturers are able to minimize their carbon footprint while delivering high-quality products.

Conclusion

Auto stamping parts are indispensable to the automotive industry, providing the structural foundation of vehicles while enabling efficient and cost-effective production. As technology advances, the processes associated with auto stamping will continue to evolve, leading to improved speed, precision, and sustainability. In a world where efficiency and innovation are paramount, auto stamping sets the stage for the future of automotive manufacturing, ensuring that vehicles can meet the demands of consumers while adhering to the principles of environmental responsibility. Manufacturers that invest in state-of-the-art stamping technology will undoubtedly secure their place in this ever-changing landscape, underscoring the importance of auto stamping in the journey toward automotive excellence.

-

crawler mounted drill rig-Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Underground Drilling Solutions, Confined Space EfficiencyNewsAug.16,2025

-

Custom OEM Couplings | Precision Machining & ManufacturingNewsAug.16,2025

-

Advanced Drilling Solutions for Confined Spaces - Baoding Hairun Machinery | Crawler Mounted Drill Rig&Confined Space ApplicationsNewsAug.16,2025

-

Drill For Confined Spaces-Crawler Drill Rig for Mining Applications|Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.16,2025

-

Crawler Mounted Drill Rig-Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Compressed Air Power&Frame SupportNewsAug.15,2025

-

Crawler Drilling Rig - Baoding Hairun|Confined Space Drilling&Mine SafetyNewsAug.15,2025