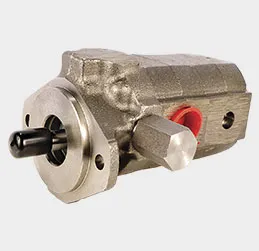

auto parts carbon steel investment precision casting manufacturer

The Rise of Precision Casting in the Auto Parts Industry

In the ever-evolving automotive sector, the demand for high-quality, durable components is paramount. Among the various manufacturing methods available, precision casting, particularly utilizing carbon steel, has emerged as a critical technique for producing auto parts that meet stringent performance standards. This article explores the significance of precision casting in the auto parts industry, the benefits of using carbon steel, and the future trends shaping this manufacturing realm.

Understanding Precision Casting

Precision casting, often referred to as investment casting, is a process characterized by its ability to create complex shapes with tight tolerances. This method involves creating a mold from a wax pattern, which is subsequently coated in a ceramic material. Once the ceramic hardens, the wax is melted away, leaving a precise cavity in the mold that can be filled with molten metal. This technique allows manufacturers to produce intricate designs that would be difficult or impossible to achieve through traditional machining methods.

The Role of Carbon Steel

Carbon steel has become one of the most preferred materials for casting in the auto parts industry. Known for its strength and durability, this alloy comprises iron and carbon, with varying amounts of other elements. The primary benefits of using carbon steel for investment casting include

1. Enhanced Mechanical Properties Carbon steel exhibits excellent strength-to-weight ratios, making it ideal for automotive applications where weight reduction is crucial without compromising performance.

2. Cost-Effectiveness Compared to other metals, carbon steel is relatively inexpensive, which helps manufacturers control production costs while delivering high-quality products.

3. Versatility This material can be alloyed with different elements to achieve specific properties, such as improved wear resistance or corrosion resistance, allowing for tailored solutions for various auto parts requirements.

4. Recyclability Carbon steel is highly recyclable, making it an environmentally friendly choice in an industry increasingly focusing on sustainability.

Applications in the Automotive Sector

Precision casting of carbon steel is widely used in manufacturing numerous auto parts, including

auto parts carbon steel investment precision casting manufacturer

- Engine Components Various engine parts, such as crankshafts, camshafts, and valve bodies, require high strength and precise dimensions

. Carbon steel investment casting meets these needs effectively.- Transmission Parts Components within the transmission, like housings and gears, benefit from the durability and dimensional accuracy provided by precision casting.

- Suspension Systems Parts such as control arms and knuckles need to withstand significant stress. The mechanical properties of carbon steel make it an ideal candidate for these critical components.

- Braking Systems Elements like brake calipers and rotors are often manufactured using carbon steel casting for their strength and ability to handle heat.

Future Trends

As the automotive industry pushes towards innovation and efficiency, precision casting will continue to play a vital role. Emerging trends include

1. Integration of Smart Technologies The use of advanced software and digital tools in designing and optimizing casting processes will enhance precision in production, leading to better quality assurance and faster turnaround times.

2. Sustainability Practices Manufacturers are increasingly adopting greener practices, focusing on reducing waste and energy consumption in the casting process. The shift towards electric vehicles and lighter materials will also drive the demand for precision casting technologies.

3. Customization and Rapid Prototyping The ability to produce customized components quickly is gaining traction. Investment casting allows for rapid prototyping, enabling manufacturers to test and develop new designs efficiently.

4. Global Supply Chain Optimization As manufacturers seek to streamline operations, precision casting partnerships across borders will facilitate access to advanced technologies and materials, enhancing overall production efficiency.

Conclusion

Precision casting using carbon steel is shaping the future of the auto parts industry by enabling the production of high-quality, intricate components that meet the demanding requirements of modern vehicles. With its combination of strength, cost-effectiveness, and versatility, carbon steel remains a cornerstone material in the manufacturing of vital automotive parts. As technology and practices continue to evolve, the role of precision casting will undoubtedly expand, paving the way for innovations that enhance vehicle performance and sustainability.

-

Custom Steel Sand Casting Services Precision & Durability GuaranteedNewsApr.29,2025

-

Arise Precision Casting Custom Metal Casting Solutions & ServicesNewsApr.29,2025

-

Sand Casting Guide Definition, Process & High-Quality Sand SuppliesNewsApr.28,2025

-

Premium Alloy Die Casting Manufacturer Aluminium & Zinc SolutionsNewsApr.28,2025

-

Precision Aluminum Die Casting Custom Solutions & Fast TurnaroundNewsApr.27,2025

-

Precision Complex Sand Casting Solutions Durable & Custom DesignsNewsApr.27,2025