metal stamping part

Understanding Metal Stamping Parts A Comprehensive Overview

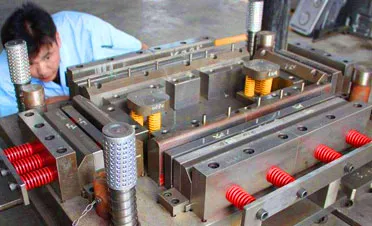

Metal stamping is a manufacturing process that involves the shaping of metal sheets into specific forms using a die and press. This technique is vital in creating a variety of metal parts used across various industries, including automotive, aerospace, electronics, and appliances. This article will explore the process of metal stamping, its applications, benefits, and considerations in the manufacturing sector.

The Metal Stamping Process

The metal stamping process begins with metal sheets, typically made of steel, aluminum, brass, or other alloys, which are fed into a stamping press. The press contains a die, a tool that shapes the metal into the desired form. The two primary methods of stamping are progressive stamping and transfer stamping.

1. Progressive Stamping In this method, a single long strip of metal is fed through a series of dies in a single stroke. Each die progressively shapes the part until it is fully formed. This method is efficient for high-volume production since it allows for the continuous processing of multiple components.

2. Transfer Stamping This process involves transferring the metal parts between different dies during the stamping operation. The parts are first cut and then transferred through a series of stations where they undergo further shaping. While this method is generally slower than progressive stamping, it allows for greater flexibility and is suitable for complex geometries.

Applications of Metal Stamping Parts

Metal stamping is widely used to create components in various sectors

- Automotive Industry Stamped metal parts are crucial in the automotive sector for manufacturing components such as brackets, frames, and body panels. The lightweight nature of stamped parts contributes to better fuel efficiency and performance.

- Aerospace Sector The aerospace industry demands high precision and reliability. Metal stamping is employed to manufacture critical components like wing structures, engine mounts, and other parts that must adhere to stringent safety regulations.

- Electronics From smartphone cases to circuit boards, metal stamping ensures the production of reliable and precise parts essential for electronic devices.

- Consumer Goods Household appliances, furniture, and various consumer products rely on metal stamping for components that facilitate assembly and functionality.

Benefits of Metal Stamping

metal stamping part

1. Efficiency Once the dies are created, metal stamping can produce large quantities of parts quickly, making it an efficient manufacturing process for businesses looking to scale up production.

2. Cost-Effectiveness Although the initial cost of creating dies can be high, the long-term savings achieved through high production rates and reduced waste often offset this expenditure. Additionally, the ability to utilize scrap material minimizes material costs.

3. Precision and Quality Metal stamping produces highly accurate and consistent parts, which is crucial for industries that require stringent quality control and adherence to specifications.

4. Versatility Stamping can accommodate a variety of materials and thicknesses, allowing manufacturers to produce an extensive range of products tailored to specific needs.

Considerations in Metal Stamping

While the advantages of metal stamping are numerous, there are considerations to keep in mind for successful implementation

- Die Design and Manufacturing The quality of the die directly impacts the quality of the final product. Investing in high-quality die manufacturing is critical to avoid costly production errors.

- Material Selection Choosing the right material for stamping is essential, as different metals offer varying properties that can affect the performance of the final product. Manufacturers must consider factors such as tensile strength, ductility, and corrosion resistance.

- Production Volume Metal stamping is most cost-effective at high volumes. Companies should assess their production needs to determine whether stamping is the best method for their product line.

- Lead Time The process of designing and producing dies can lead to longer lead times initially. Therefore, companies should plan accordingly to mitigate delays in production.

Conclusion

Metal stamping is a vital manufacturing process that serves multiple industries by producing precise, high-quality metal parts. With its efficiency, cost-effectiveness, and versatility, it plays a significant role in modern manufacturing. As technologies advance and industries evolve, metal stamping will continue to adapt, ensuring its place in the future of manufacturing. Understanding the intricacies of this process is essential for companies looking to leverage metal stamped parts for their production needs.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025