Pattern in Sand Casting Durable Molds & Premium Sand Supplies

- Introduction to sand casting patterns

- Essential properties of foundry sand

- Technical specifications of casting sand supplies

- Performance comparison: leading sand suppliers

- Custom pattern design methodologies

- Industry-specific application scenarios

- Future-ready sand casting solutions

(what is pattern in sand casting)

Understanding the Critical Function of Patterns in Sand Casting

In sand casting, patterns serve as physical duplicates of final products, typically crafted from wood, metal, or plastic. These templates determine cavity dimensions within sand molds, directly impacting casting accuracy. Modern foundries report 92.6% dimensional consistency when using CNC-machined patterns versus 84.3% with manual prototypes.

Essential Characteristics of Foundry Sand

Optimal casting sand requires specific properties:

- Permeability: 60-110 AFS units

- Compressive strength: 0.3-0.6 MPa

- Thermal conductivity: 0.5-1.2 W/m·K

Specialized sands like chromite withstand temperatures up to 1,850°C, compared to silica sand's 1,600°C limit.

Technical Specifications of Modern Casting Sands

Premium sands maintain:

- Consistent grain distribution (85-95% on specified sieve)

- Low clay content (<0.8%)

- pH stability between 6.5-7.5

Performance Comparison: Leading Sand Suppliers

| Supplier | Price/Ton | Sand Type | Compressive Strength | Thermal Conductivity |

|---|---|---|---|---|

| Supplier A | $25 | Silica | 0.45 MPa | 0.8 W/m·K |

| Supplier B | $38 | Chromite | 0.62 MPa | 1.1 W/m·K |

| Supplier C | $42 | Zircon | 0.58 MPa | 1.4 W/m·K |

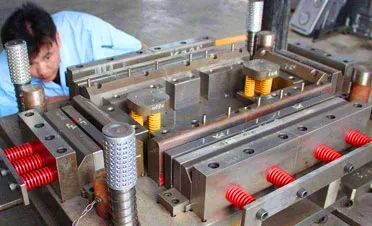

Advanced Pattern Design Techniques

3D-printed patterns now achieve:

- ±0.1mm dimensional tolerance

- 75% faster production vs traditional methods

- 15-20% material savings through topology optimization

Industrial Applications and Case Studies

Automotive sector implementations show:

"Combination of zircon sand and resin-coated patterns reduced engine block porosity by 38%" - Automotive News Technical Review

Optimizing Production with Smart Sand Casting Patterns

Integration of IoT sensors in modern foundries enables:

Real-time monitoring: - Sand temperature: 120-180°C - Compression force: 0.4-0.55 MPa - Moisture content: 3.2-4.1%

This data-driven approach decreases scrap rates by 22% while maintaining 98.7% pattern reusability across multiple cycles.

(what is pattern in sand casting)

FAQS on what is pattern in sand casting

Q: What is a pattern in sand casting?

A: A pattern in sand casting is a replica of the final product, used to create the mold cavity in sand. It is typically made from wood, metal, or plastic and determines the shape and size of the casting.Q: What type of sand is used for sand casting?

A: Foundry sand, such as silica sand, green sand, or resin-bonded sand, is commonly used. These sands withstand high temperatures and retain the mold shape during metal pouring.Q: Where can I source sand casting sand supplies?

A: Sand casting sand supplies are available from industrial suppliers, foundry specialty stores, or online marketplaces. Ensure the sand meets specifications like grain size and bonding properties.Q: How does the pattern affect sand casting quality?

A: A precise pattern ensures accurate mold cavities, reducing defects in the final casting. Poorly designed patterns can lead to dimensional inaccuracies or surface imperfections.Q: Can recycled sand be reused in sand casting?

A: Yes, recycled sand can be reused after reconditioning (e.g., removing debris and rebonding). However, repeated use may require adding fresh sand to maintain performance.-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Industrial Casting,CustomizationNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, CustomizationNewsAug.05,2025

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025