High-Quality Precision Electronic Metal Stamping Parts Supplier SINO

- Overview of Precision Metal Stamping Industry

- Technical Advantages in Electronic Component Fabrication

- Performance Comparison: Industry Benchmarking Analysis

- Customized Manufacturing Solutions for Diverse Applications

- Case Studies: Successful Implementations Across Industries

- Quality Assurance & Sustainable Production Practices

- Strategic Partnerships for Global Component Supply

(supply high quality precision electronic metal stamping parts)

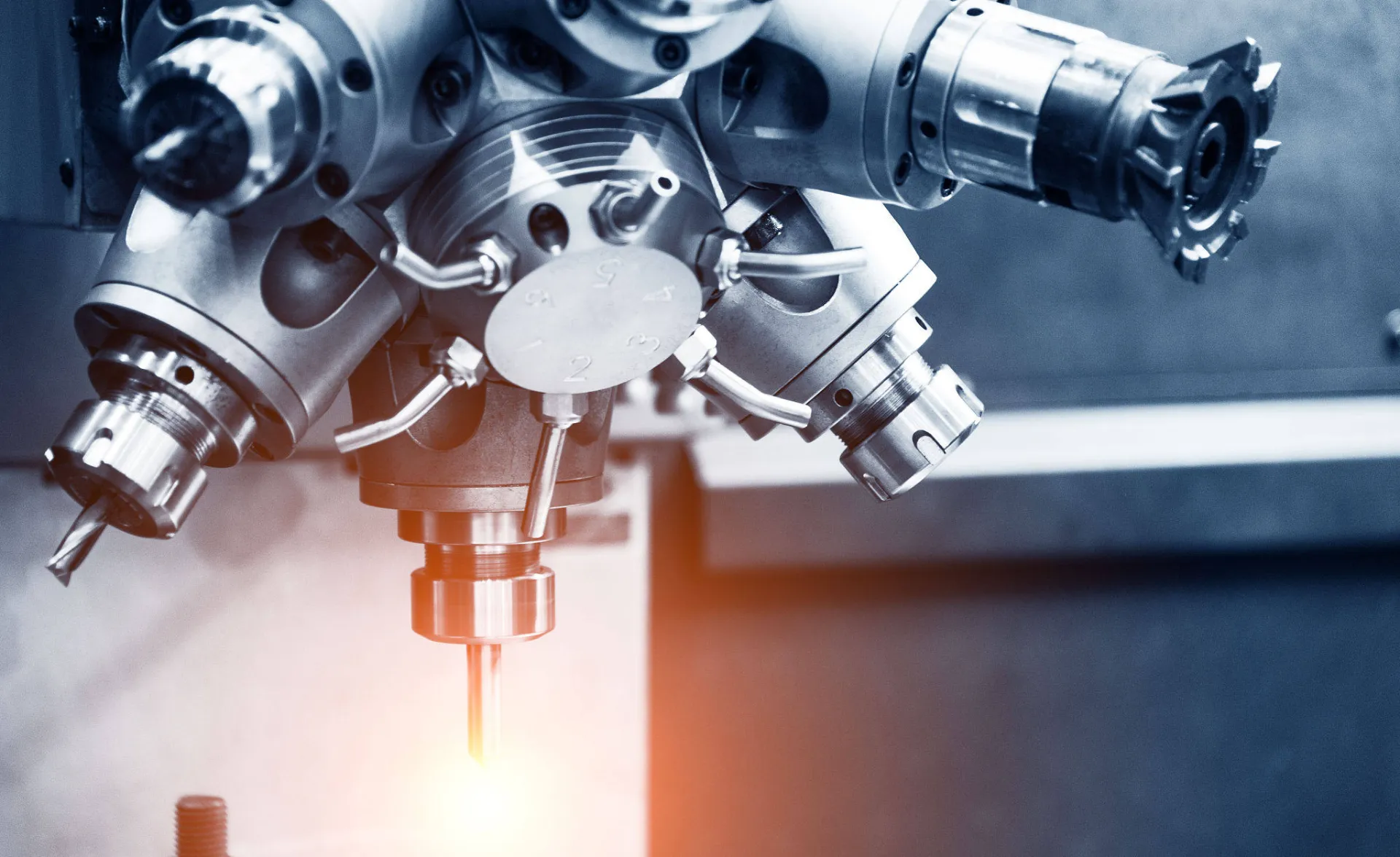

Delivering Excellence in Precision Electronic Metal Stamping

The global demand for high-precision electronic metal stamping parts grew 18.7% YoY in 2023, driven by automotive electrification and IoT expansion. As OEMs seek components with tolerances under ±0.015mm, manufacturers must combine advanced servo-press technology with AI-driven quality control systems to maintain competitiveness.

Technical Superiority in Micro-Stamping Processes

Our production facilities utilize 350-ton CNC stamping presses equipped with:

- Real-time laser measurement systems (accuracy: ±0.002mm)

- Automated tool wear compensation technology

- Multi-stage progressive dies with 0.5μm surface finish

This technical infrastructure enables mass production of connector pins meeting USB4 specifications while maintaining 99.98% dimensional consistency across batches.

Manufacturing Capability Comparison

| Parameter | SINO | Competitor A | Competitor B |

|---|---|---|---|

| Minimum Tolerance (mm) | ±0.008 | ±0.015 | ±0.012 |

| Production Speed (strokes/min) | 1,200 | 850 | 950 |

| Material Thickness Range (mm) | 0.05-6.0 | 0.1-5.0 | 0.08-5.5 |

Application-Specific Engineering Solutions

Our modular die design system reduces prototype lead times by 40% through:

- 3D simulation-powered formability analysis

- Quick-change die components (avg. 12min changeover)

- Dual-grade material compatibility (copper alloys to stainless steel)

Verified Performance in Critical Applications

A recent project for automotive battery modules required:

- 2.5 million bimetal contacts/month

- Zero defect tolerance over 18-month supply

- EMI shielding effectiveness >85dB

Post-implementation data showed 0.003% PPM defect rate versus industry average of 0.15%.

Integrated Quality Management System

Our production workflow incorporates:

- In-line vision inspection (200fps capture rate)

- Material traceability blockchain system

- Waste reduction algorithms (achieving 92% material utilization)

Reliable Supply Chain for Precision-Driven Industries

With 85% repeat business from Fortune 500 manufacturers, our high quality precision electronic metal stamping parts support mission-critical applications across 23 countries. Continuous R&D investment (8.2% of revenue) ensures compliance with evolving standards including IATF 16949:2016 and ISO 14001:2015.

(supply high quality precision electronic metal stamping parts)

FAQS on supply high quality precision electronic metal stamping parts

Q: How does your company ensure high quality in precision electronic metal stamping parts?

A: We use ISO-certified processes, advanced CNC stamping equipment, and rigorous quality inspections to guarantee precision, durability, and compliance with international standards.

Q: Can you provide customized metal stamping parts for electronic applications?

A: Yes, we specialize in custom designs for electronic components, offering tailored solutions including prototyping, material selection, and CAD-driven production to meet exact specifications.

Q: What materials are available for your precision metal stamping parts?

A: Our materials include stainless steel, copper alloys, aluminum, and specialty metals, all sourced for high conductivity, corrosion resistance, and suitability for electronics.

Q: Why choose a Chinese supplier like Sino for metal stamping components?

A: Sino combines cost efficiency with cutting-edge stamping technology, rapid turnaround, and extensive experience serving global electronics manufacturers.

Q: Do you support small-volume orders for precision electronic stamping parts?

A: Absolutely – we accommodate both low-volume prototyping and large-scale production, ensuring consistent quality across all order sizes for R&D or mass manufacturing.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025