Yan . 19, 2025 01:01

Back to list

precision foundry tooling

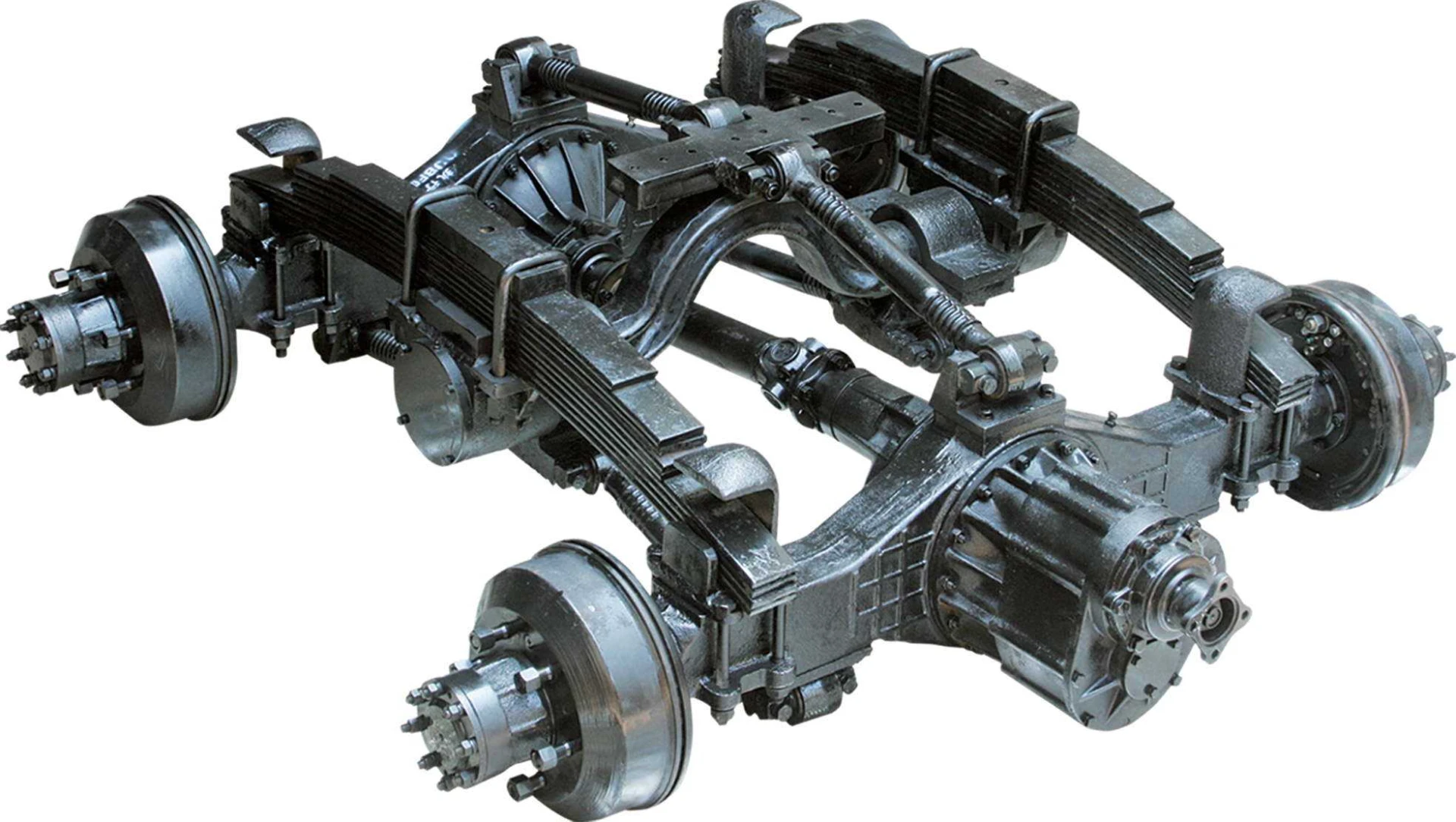

The transformative power of precision foundry tooling lies not only in enhancing production processes but also in facilitating the creation of unmatched, intricate components that meet the demanding requirements of modern engineering and manufacturing realms. For entities seeking optimal performance and longevity in their foundry processes, leveraging precision foundry tooling offers an unparalleled competitive edge. This article explores the core aspects of precision foundry tooling and why it is a pivotal investment in the manufacturing industry.

From a consumer perspective, investing in precision foundry tooling means ensuring the integrity of their production line. The reduction in manufacturing errors not only improves the quality of the final product but also enhances the efficiency of the production process itself. By minimizing the margin of error, companies avoid costly reworks and defects, leading to a more streamlined and economical operation. Experience in handling precision foundry tooling is another crucial determinant of success. Seasoned professionals who bring years of experiential knowledge offer invaluable insights that go beyond theoretical expertise. Their experience provides them with unique foresight and problem-solving abilities, which are pivotal when customizing tooling solutions tailored to specific industrial needs. The integration of precision foundry tooling with advanced technology is revolutionizing industries. Digital simulations and prototypes allow for the testing and refinement of tools before they are implemented in production, reducing the risk of errors and improving efficiency. Furthermore, the advent of Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, enhances the capacity for real-time monitoring and optimization of tooling processes. As manufacturers face increasing pressure to deliver precision components faster and more cost-effectively, the demand for precision foundry tooling is poised to grow. Companies that embrace this technology today are paving the way for innovation, sustainability, and excellence in production. As a result, they are better positioned to meet the evolving needs of their clients and secure a commanding presence in the global market. In summary, the adoption of precision foundry tooling is essential for any manufacturing entity aiming for superiority, reliability, and efficiency in its production line. By leveraging advanced technologies, fostering industry expertise, and maintaining ethical integrity, companies can harness the full potential of precision foundry tooling, achieving what was once deemed impossible in the realms of manufacturing precision and excellence.

From a consumer perspective, investing in precision foundry tooling means ensuring the integrity of their production line. The reduction in manufacturing errors not only improves the quality of the final product but also enhances the efficiency of the production process itself. By minimizing the margin of error, companies avoid costly reworks and defects, leading to a more streamlined and economical operation. Experience in handling precision foundry tooling is another crucial determinant of success. Seasoned professionals who bring years of experiential knowledge offer invaluable insights that go beyond theoretical expertise. Their experience provides them with unique foresight and problem-solving abilities, which are pivotal when customizing tooling solutions tailored to specific industrial needs. The integration of precision foundry tooling with advanced technology is revolutionizing industries. Digital simulations and prototypes allow for the testing and refinement of tools before they are implemented in production, reducing the risk of errors and improving efficiency. Furthermore, the advent of Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, enhances the capacity for real-time monitoring and optimization of tooling processes. As manufacturers face increasing pressure to deliver precision components faster and more cost-effectively, the demand for precision foundry tooling is poised to grow. Companies that embrace this technology today are paving the way for innovation, sustainability, and excellence in production. As a result, they are better positioned to meet the evolving needs of their clients and secure a commanding presence in the global market. In summary, the adoption of precision foundry tooling is essential for any manufacturing entity aiming for superiority, reliability, and efficiency in its production line. By leveraging advanced technologies, fostering industry expertise, and maintaining ethical integrity, companies can harness the full potential of precision foundry tooling, achieving what was once deemed impossible in the realms of manufacturing precision and excellence.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

Genuine OEM Lamps: Projector, LED, & Light Bulbs for All NeedsNewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Fluid ControlNewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, Customizable SolutionsNewsAug.08,2025

PRODUCTS CATEGORIES