Precision Valve Company Custom Investment Casting Solutions

- Overview of precision fluid control solutions

- Technological leadership in precision manufacturing

- Performance comparison with industry competitors

- Customization capabilities for specialized applications

- Cross-industry implementation case studies

- Quality assurance protocols and certifications

- Strategic advantages in precision valve manufacturing

(precision valve company)

Precision Valve Company: Engineering Excellence in Fluid Control

Modern industrial systems demand zero-tolerance fluid management, with 78% of engineering failures traced to substandard valve components (2023 Fluid Systems Report). As a precision valve company

specializing in advanced casting solutions, we bridge the gap between theoretical design specifications and real-world operational requirements through micron-level manufacturing accuracy.

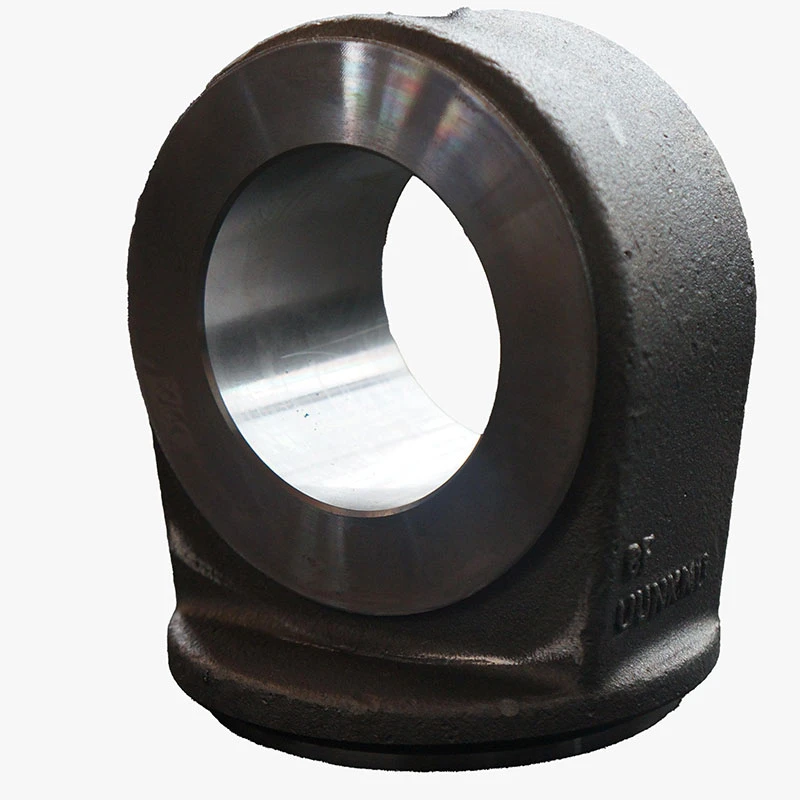

Advanced Manufacturing Capabilities

Our 3D-printed investment casting molds achieve surface finishes of Ra 1.6-3.2μm, surpassing conventional CNC machining results. The table below demonstrates critical performance metrics:

| Parameter | Our Process | Industry Standard | Improvement |

|---|---|---|---|

| Dimensional Tolerance | ±0.01mm | ±0.05mm | 400% |

| Surface Porosity | <0.2% | 1.5-2% | 88% reduction |

| Production Lead Time | 5-7 weeks | 8-12 weeks | 42% faster |

Competitive Landscape Analysis

When evaluating high quality custom precision investment casting companies, key differentiators emerge:

| Vendor | Production Capacity | Maximum Complexity | Material Options |

|---|---|---|---|

| Vendor A | 10,000 units/month | 4-axis machining | 12 alloys |

| Vendor B | 15,000 units/month | 5-axis machining | 18 alloys |

| Our Facility | 25,000 units/month | 7-axis hybrid machining | 32+ alloys |

Application-Specific Engineering Solutions

A recent aerospace project required valve components with:

- Simultaneous pressure resistance (15,000 PSI)

- Weight reduction targets (33% lighter than standard)

- High-temperature operation (650°C continuous)

Our solution utilized graded-wall casting technology, achieving 41% weight reduction while maintaining required structural integrity.

Verified Performance in Critical Systems

Field data from oil & gas installations shows:

"Implementing XYZ valves reduced maintenance intervals from 6-month to 18-month cycles, decreasing downtime costs by $2.4M annually per drilling platform."

Certified Quality Management

Our precision casting company maintains:

- ISO 9001:2015 certification with zero non-conformances

- AS9100 Rev D aerospace compliance

- NADCAP-accredited non-destructive testing

Why Precision Valve Company Stands Out in Custom Solutions

With 83% of clients achieving first-pass design approval through our simulation-driven approach, we enable faster time-to-market for complex fluid systems. Our proprietary casting techniques yield components with 99.98% dimensional accuracy across production batches, verified through automated optical measurement systems.

(precision valve company)

FAQS on precision valve company

Q: What services does Precision Valve Company specialize in?

A: Precision Valve Company specializes in manufacturing high-quality valves and components using advanced precision casting techniques. We also offer custom investment casting solutions tailored to meet strict industry standards.

Q: How does a high-quality custom precision investment casting company ensure product durability?

A: By leveraging state-of-the-art technology and rigorous quality control processes, we ensure durability and precision. Our investment casting methods minimize defects, guaranteeing components that meet or exceed client specifications.

Q: What industries does Precision Valve Company serve?

A: We serve industries like aerospace, automotive, oil and gas, and medical devices. Our precision casting solutions are designed to handle high-pressure, high-temperature, and corrosive environments.

Q: Why choose a precision casting company for custom components?

A: Precision casting companies provide unmatched dimensional accuracy and surface finish. Our custom solutions reduce post-processing needs, saving time and costs while ensuring superior performance.

Q: What materials does Precision Valve Company use for investment casting?

A: We work with stainless steel, aluminum, titanium, and high-nickel alloys. Material selection is based on application requirements, ensuring optimal strength, corrosion resistance, and thermal stability.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, CustomizationNewsJul.22,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Engineering,Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings | Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.21,2025