Fev . 14, 2025 16:54

Back to list

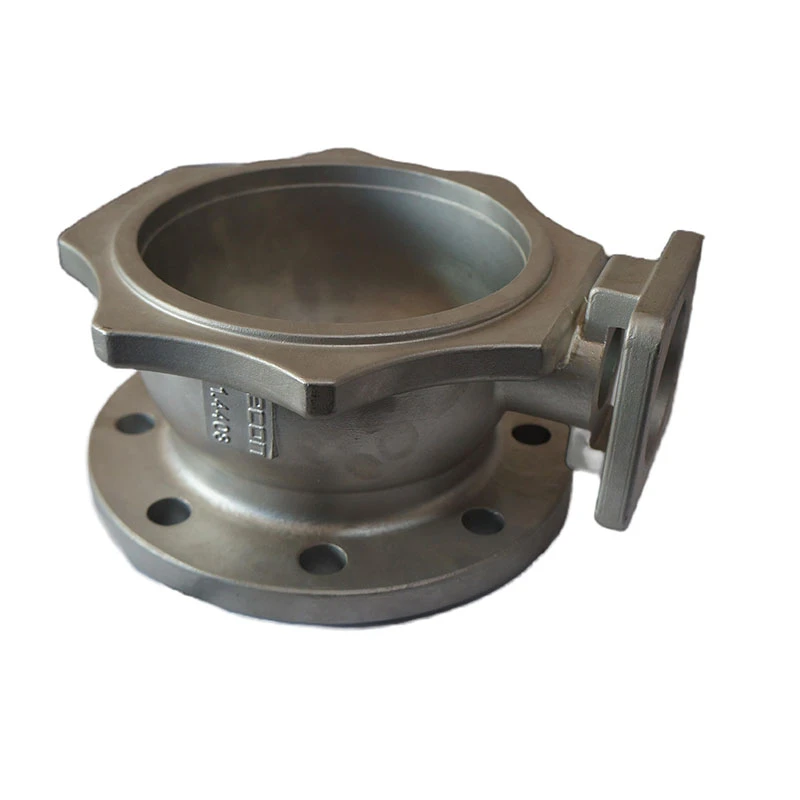

metal stampings manufacturer

High Pressure Die Casting (HPDC) is an advanced manufacturing process that has transformed the way complex metal parts are fabricated across various industries. The technique involves injecting molten metal into a die under high pressure, creating intricately detailed components with remarkable precision and efficiency. Companies leveraging HPDC dies gain a competitive edge by producing high-quality products while maintaining cost-effective operations.

Trustworthiness is a cornerstone that businesses must cultivate to thrive in the competitive manufacturing landscape. Companies that utilize HPDC dies emphasize transparency in their operations, providing clients with detailed insights into their manufacturing processes and quality control measures. Advanced quality assurance techniques, such as X-ray inspection and spectroscopic analysis, are employed to ensure the structural integrity and composition of the casts meet the highest standards. By offering meaningful guarantees and comprehensive post-sale support, manufacturers instill confidence in their clientele, fostering long-term business relationships. The flexibility of HPDC dies cannot be overstated. They allow for the production of a diverse range of parts, from simple shapes to complex geometries, tailored to the specific needs of different industries. This versatility means businesses can quickly adapt to changing market demands and innovate with new designs without compromising production efficiency. The ability to seamlessly integrate with automated systems also enhances the scalability of operations, enabling companies to increase output without a proportional rise in costs. In conclusion, HPDC dies represent a critical technology in modern manufacturing, offering unmatched benefits in terms of precision, efficiency, and versatility. Companies that master this process not only gain a significant competitive edge but also establish themselves as leaders in producing high-quality metal components. By focusing on expertise, authoritativeness, and trustworthiness, these businesses build a strong foundation for growth and success in the global marketplace. As industries continue to push the boundaries of what's possible, HPDC dies stand as a testament to innovation in manufacturing, driving progress and setting new standards for excellence.

Trustworthiness is a cornerstone that businesses must cultivate to thrive in the competitive manufacturing landscape. Companies that utilize HPDC dies emphasize transparency in their operations, providing clients with detailed insights into their manufacturing processes and quality control measures. Advanced quality assurance techniques, such as X-ray inspection and spectroscopic analysis, are employed to ensure the structural integrity and composition of the casts meet the highest standards. By offering meaningful guarantees and comprehensive post-sale support, manufacturers instill confidence in their clientele, fostering long-term business relationships. The flexibility of HPDC dies cannot be overstated. They allow for the production of a diverse range of parts, from simple shapes to complex geometries, tailored to the specific needs of different industries. This versatility means businesses can quickly adapt to changing market demands and innovate with new designs without compromising production efficiency. The ability to seamlessly integrate with automated systems also enhances the scalability of operations, enabling companies to increase output without a proportional rise in costs. In conclusion, HPDC dies represent a critical technology in modern manufacturing, offering unmatched benefits in terms of precision, efficiency, and versatility. Companies that master this process not only gain a significant competitive edge but also establish themselves as leaders in producing high-quality metal components. By focusing on expertise, authoritativeness, and trustworthiness, these businesses build a strong foundation for growth and success in the global marketplace. As industries continue to push the boundaries of what's possible, HPDC dies stand as a testament to innovation in manufacturing, driving progress and setting new standards for excellence.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES