Yan . 30, 2025 01:01

Back to list

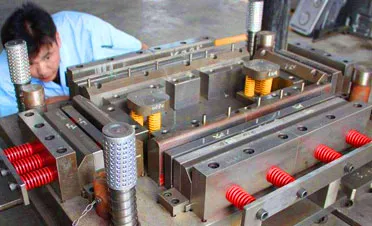

greensand casting sand

Greensand casting, often revered in the foundry industry, stands as a unique and versatile method for producing metal castings. This technique derives its name from green sand—a mixture of sand, clay, and water—employed to form molds for metal parts. As sustainability and cost-effectiveness become increasingly important in manufacturing, greensand casting offers unparalleled benefits that make it a crucial choice for modern production facilities.

Trustworthiness is a defining attribute of greensand casting sand. The method's proven track record in producing durable and reliable castings cements its reputation among manufacturers. It supports diverse industries, from automotive to heavy machinery, each demanding stringent quality measures. The eco-friendly nature of greensand also adds to its trustworthiness; as most of the sand can be recycled, it reduces waste and promotes sustainable production practices. This sustainable edge aligns with modern trends towards environmentally conscious manufacturing. For product developers, the benefits of greensand casting sand are multifaceted. Its cost efficiency is remarkable; with lower material costs compared to alternatives and the ability for mold reuse, it reduces overall production expenses. Such economic advantages are complemented by the method’s swift turnaround time, crucial for industries that require rapid prototyping and production. Moreover, the adaptability of greensand casting to various sizes and shapes makes it invaluable for custom and complex projects without compromising on quality or integrity. In combining these facets—experience in molding complex shapes, professional expertise in process adaptation, authoritative standing through historical and continuous use, and inherent trustworthiness due to sustainability and cost-effectiveness—greensand casting sand rises to the forefront of modern foundry solutions. Those looking to leverage its full potential will find that investing in expert consultation and staying abreast of technological advancements allows for the maximization of benefits this timeless technique offers. As the manufacturing landscape evolves, maintaining a competitive edge requires innovation and strategic resource use. Greensand casting sand provides a blend of tradition and modernity, making it an exemplary choice for companies aiming to enhance their product lines while adhering to sustainable practices and economic prudence.

Trustworthiness is a defining attribute of greensand casting sand. The method's proven track record in producing durable and reliable castings cements its reputation among manufacturers. It supports diverse industries, from automotive to heavy machinery, each demanding stringent quality measures. The eco-friendly nature of greensand also adds to its trustworthiness; as most of the sand can be recycled, it reduces waste and promotes sustainable production practices. This sustainable edge aligns with modern trends towards environmentally conscious manufacturing. For product developers, the benefits of greensand casting sand are multifaceted. Its cost efficiency is remarkable; with lower material costs compared to alternatives and the ability for mold reuse, it reduces overall production expenses. Such economic advantages are complemented by the method’s swift turnaround time, crucial for industries that require rapid prototyping and production. Moreover, the adaptability of greensand casting to various sizes and shapes makes it invaluable for custom and complex projects without compromising on quality or integrity. In combining these facets—experience in molding complex shapes, professional expertise in process adaptation, authoritative standing through historical and continuous use, and inherent trustworthiness due to sustainability and cost-effectiveness—greensand casting sand rises to the forefront of modern foundry solutions. Those looking to leverage its full potential will find that investing in expert consultation and staying abreast of technological advancements allows for the maximization of benefits this timeless technique offers. As the manufacturing landscape evolves, maintaining a competitive edge requires innovation and strategic resource use. Greensand casting sand provides a blend of tradition and modernity, making it an exemplary choice for companies aiming to enhance their product lines while adhering to sustainable practices and economic prudence.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Fluid Control & Custom CastingNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Customization&Quality AssuranceNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.08,2025

-

Precision Aluminium Die Casting Companies - Custom SolutionsNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering, Industrial Fluid ControlNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

PRODUCTS CATEGORIES