aluminium die casting parts manufacturer

The Evolution and Benefits of Aluminium Die Casting Parts Manufacturing

Aluminium die casting is a dominant manufacturing process in modern industries, particularly in sectors such as automotive, aerospace, electronics, and consumer goods. As a versatile and efficient technique, it offers numerous advantages, making it a go-to solution for producing parts with complex shapes and high dimensional accuracy. This article explores the significant aspects of aluminium die casting parts manufacturing, highlighting its evolution, processes, and benefits.

The Evolution of Aluminium Die Casting

The use of aluminium in manufacturing dates back to the early 19th century, but it was not until the mid-20th century that die casting gained traction as a mass production technique. The advantages of aluminium, such as its lightweight and corrosion-resistant properties, became increasingly valuable during the post-war industrial boom. As industries sought to create efficient, lightweight components, the adoption of aluminium die casting soared.

Over the years, advancements in die casting technology have revolutionized the manufacturing process. Innovations in alloy development, die materials, and injection systems have significantly improved the performance and efficiency of aluminium die casting. Today, automated machinery and sophisticated numerical control systems allow manufacturers to achieve higher productivity and precision, catering to the growing demands of the market.

The Die Casting Process

Aluminium die casting involves several key steps

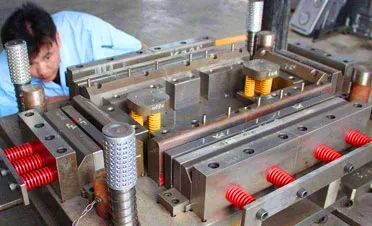

1. Mold Creation The process begins with the design and fabrication of a metal die or mold, typically made from tool steel. The die is created to exact specifications to ensure the desired part dimensions and tolerances.

2. Melting and Injection Aluminium is melted in a furnace and then injected at high pressure into the prepared die. The injection speed and pressure are crucial as they determine the quality and detail of the cast part.

3. Cooling and Solidification Once injected, the molten aluminium fills the mold cavity and begins to cool. The cooling phase is critical, as it affects the mechanical properties and surface finish of the final product.

aluminium die casting parts manufacturer

4. Ejection and Finishing After the casting solidifies, the die is opened, and the part is ejected. Post-processing steps, such as trimming, machining, and surface treatment, may be necessary to meet the specific requirements of the component.

Advantages of Aluminium Die Casting

Aluminium die casting presents several advantages over other manufacturing processes

- High Precision The die casting process yields parts with excellent dimensional accuracy and surface finish. This precision minimizes the need for additional machining, reducing production time and costs.

- Lightweight Strength Aluminium is known for its strength-to-weight ratio, making it an ideal choice for industries that prioritize weight savings, such as automotive and aerospace. Components produced via die casting are strong yet lightweight, enhancing overall efficiency.

- Complex Geometries Die casting allows for the creation of intricate shapes and designs that would be challenging or impossible to achieve with other manufacturing methods. This capability enables engineers to innovate and optimize product designs.

- Cost-Effective Production While the initial tooling costs for die casting can be high, the process is highly efficient for high-volume production. As a result, the per-unit cost decreases substantially with increased production runs, making it a cost-effective solution for mass production.

- Sustainability Aluminium is recyclable, and the die casting process generates minimal waste. Manufacturers can reclaim and reuse scrap material, contributing to a more sustainable production cycle.

Conclusion

As industries continue to evolve, the demand for high-quality, efficient manufacturing processes will only grow. Aluminium die casting stands out as a robust solution that meets these demands by offering precision, cost-effectiveness, and sustainability. Manufacturers who invest in advanced die casting technology and stay abreast of industry trends are well-positioned to harness the potential of aluminium die casting parts, driving innovation and efficiency in their operations. Whether for automotive components, consumer electronics, or complex aerospace parts, aluminium die casting remains a cornerstone of modern manufacturing, poised for continued growth and development in the years to come.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025