OEM Precision Casting Solutions for High-Quality Manufacturing and Custom Parts Production

The Significance of OEM Precision Casting in Today's Manufacturing Landscape

In the ever-evolving world of manufacturing, precision casting has emerged as a critical process that caters to the demands for high-quality and intricate components. Original Equipment Manufacturers (OEMs) increasingly rely on precision casting to produce parts that meet specific performance criteria while optimizing production efficiency. This article explores the significance of OEM precision casting, its benefits, and its applications across various industries.

OEM precision casting involves the production of components by creating an exact mold from which a metal is poured. The result is a high-quality part that requires minimal machining and finishing, thus saving both time and resources. This method is particularly advantageous for OEMs, who often need parts that must integrate seamlessly with their existing products while conforming to stringent quality standards.

The Significance of OEM Precision Casting in Today's Manufacturing Landscape

Cost-effectiveness is another significant advantage of precision casting for OEMs. By reducing material waste and minimizing the need for secondary finishing processes, manufacturers can lower overall production costs while maintaining high standards of quality. Additionally, precision casting allows for the mass production of components, which is crucial for OEMs relying on a steady supply of parts to keep production lines running smoothly.

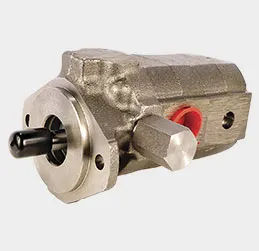

oem precision casting

Moreover, precision casting is versatile, accommodating a wide range of metals and alloys, including aluminum, steel, and stainless steel. This versatility enables OEMs to select the most appropriate materials for their applications, considering factors like weight, strength, and resistance to corrosion and wear. For example, in the automotive industry, precision-cast aluminum parts are favored for their lightweight properties, contributing to fuel efficiency and performance.

As sustainability becomes an increasingly important topic in manufacturing, OEM precision casting aligns well with eco-friendly practices. The process generates less waste compared to subtractive manufacturing techniques, and the ability to recycle casting materials further enhances its environmental profile. By choosing precision casting, OEMs can not only meet their production needs but also adhere to corporate social responsibility goals.

Additionally, advancements in technology are revolutionizing OEM precision casting. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) has streamlined the design and production process, allowing for enhanced precision and speed. Furthermore, the rise of 3D printing technology in pattern making is transforming how molds are created, leading to even greater efficiencies and reduced lead times.

In various sectors, the application of OEM precision casting is significant. In the energy sector, it is used to produce components for turbines and reactors, while in the medical field, precision casting facilitates the creation of intricate surgical instruments and implants. The construction industry benefits from precision-cast parts in heavy machinery and structural components, highlighting the broad relevance of this manufacturing technique across multiple domains.

In conclusion, OEM precision casting is a cornerstone of modern manufacturing, providing OEMs with the ability to produce high-quality, complex, and cost-effective components. With its advantages in material efficiency, versatility, and sustainability, precision casting is poised to play a crucial role in the future of manufacturing. As industries continue to evolve and demand for customized solutions grows, precision casting remains an invaluable process that meets the diverse needs of OEMs worldwide.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025