High Pressure Aluminum Die Casting: Revolutionizing Precision Manufacturing

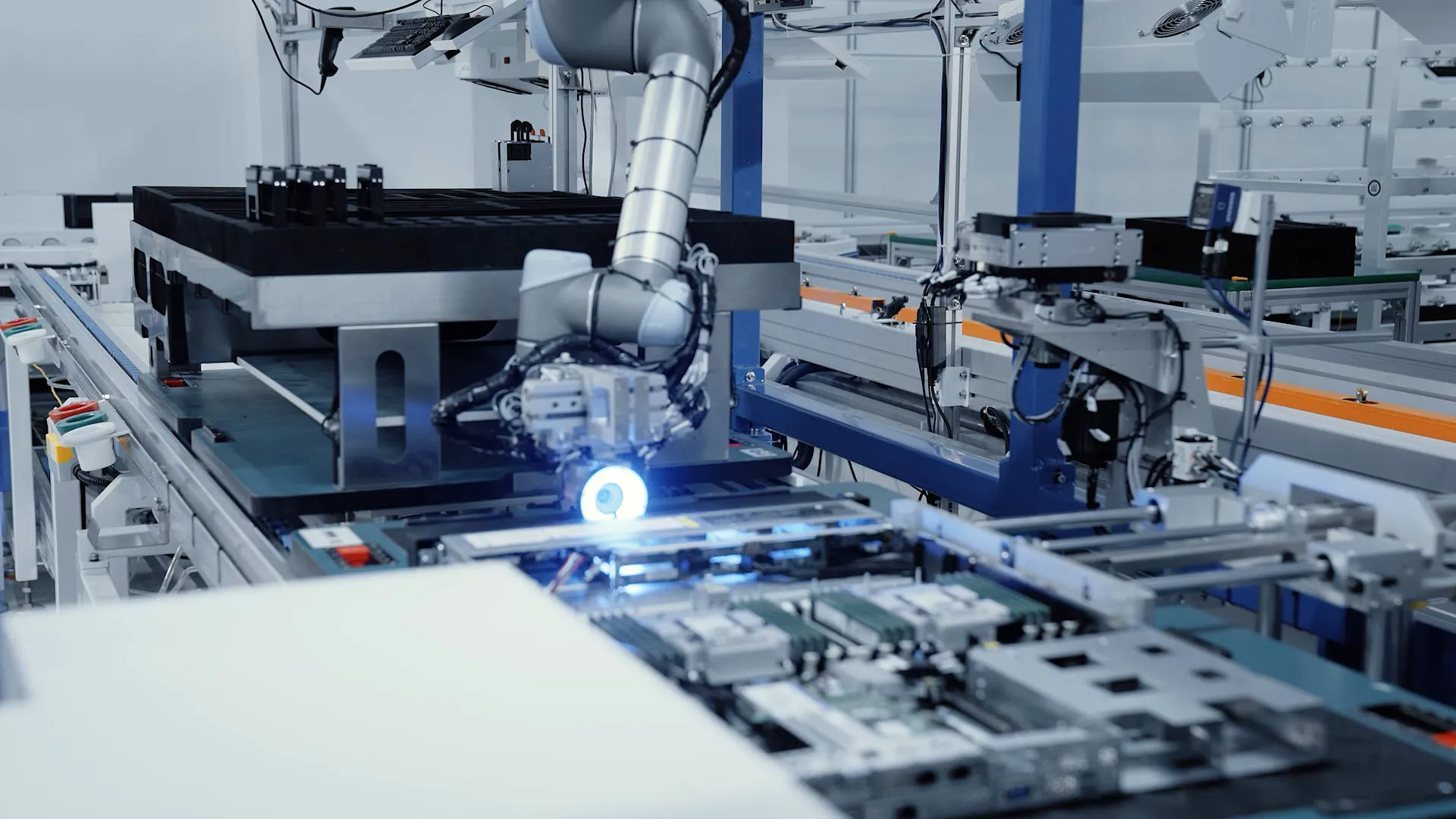

High pressure aluminum die casting is a manufacturing process that plays a critical role in producing intricate and high-quality aluminum components. In this process, molten aluminum is injected into a steel mold under high pressure, resulting in parts that have excellent dimensional accuracy, smooth surfaces, and high strength. This technique is particularly beneficial for creating components with complex shapes that require precision and uniformity, such as those used in the automotive, electronics, and aerospace industries.

The key advantage of high pressure aluminum die casting is the ability to produce large volumes of parts quickly and efficiently, with minimal waste. This makes it an ideal choice for industries looking for cost-effective, high-performance components. Parts produced through high pressure aluminum die casting are known for their structural integrity, making them suitable for demanding applications where strength and durability are critical.

Moreover, high pressure aluminum die casting offers versatility in terms of design flexibility, allowing manufacturers to produce both small and large parts with varying levels of complexity. This adaptability, combined with the fast production process, makes it a highly attractive option for businesses looking to stay competitive in a fast-paced market.

Aluminium Die Casting Companies: Leading the Industry with Expertise

When selecting a partner for aluminum die casting, it is crucial to work with reputable aluminium die casting companies that have the expertise, experience, and technology to deliver high-quality results. These companies specialize in designing and producing complex aluminum components using the die casting process, ensuring that each part meets the specific requirements of the customer.

Aluminium die casting companies offer a wide range of services, from initial design and prototyping to mass production. These companies are equipped with state-of-the-art machinery and use advanced techniques to ensure precision and efficiency. By working with such companies, businesses can access cutting-edge technologies that enhance the quality and reliability of their products.

What sets aluminium die casting companies apart is their ability to handle both large and small production runs, while maintaining the highest standards of quality. Their knowledge of different alloys, mold design, and casting techniques enables them to provide tailored solutions for diverse industries, from automotive and electronics to industrial machinery and consumer products.

Aluminium Die Casting Price: Understanding the Cost Factors

When considering aluminium die casting, understanding the pricing structure is essential for making an informed decision. The aluminium die casting price is influenced by several factors, including the complexity of the part design, the material used, the size of the production run, and the type of mold required.

In general, the aluminium die casting price can be higher compared to other casting methods due to the initial cost of creating molds and the high pressure injection process. However, the cost-efficiency of this method becomes apparent when considering the long-term benefits, such as faster production times and reduced waste. For businesses that require high volumes of precise parts, the initial investment in die casting molds can be offset by the rapid production capabilities and lower per-unit cost of casting.

Additionally, the aluminium die casting price varies depending on the complexity of the part, with intricate designs or specialized materials typically costing more. It is important for businesses to work closely with their aluminium die casting supplier to ensure that they get the best value for their investment. Understanding these cost factors and negotiating with manufacturers can help businesses achieve cost-effective production without sacrificing quality.

Aluminium Die Casting Components: Versatility and Durability in Every Part

One of the most significant advantages of aluminium die casting is the wide range of aluminium die casting components it can produce. From automotive parts to electronics housings, aluminium die casting components offer versatility and durability that are crucial for modern manufacturing. These components are used in industries ranging from automotive and aerospace to medical devices and consumer electronics, thanks to their lightweight, strong, and corrosion-resistant properties.

The process of aluminium die casting allows manufacturers to produce a variety of components, including engine parts, housings, brackets, and intricate electronic components, all with exceptional precision and surface finish. The ability to produce these components quickly and accurately makes aluminium die casting components a popular choice for industries requiring high-performance parts that can withstand harsh conditions.

Furthermore, aluminium die casting components are highly customizable, making it possible to create parts with different sizes, shapes, and finishes to meet the specific needs of each industry. Whether you're producing high-strength automotive parts or lightweight components for electronics, aluminium die casting delivers parts that meet the most demanding specifications.

Die Cast Aluminum Properties: Ensuring Strength and Longevity

The exceptional properties of die cast aluminum make it a top choice for manufacturing parts that require strength, durability, and lightweight characteristics. Die cast aluminum properties include excellent dimensional accuracy, high tensile strength, corrosion resistance, and the ability to withstand high temperatures. These properties make it an ideal material for a wide range of industries, including automotive, aerospace, and industrial machinery.

One of the key advantages of die cast aluminum is its lightweight nature, which is essential for industries such as automotive and aerospace, where reducing weight can lead to improved performance and fuel efficiency. Die cast aluminum properties also include high thermal and electrical conductivity, making it a preferred choice for parts that need to conduct heat or electricity efficiently, such as heat exchangers and electrical housings.

Moreover, die cast aluminum is highly resistant to corrosion, which is crucial for parts exposed to harsh environments. This property makes it ideal for producing components that will be used outdoors or in marine applications, where resistance to rust and wear is essential. The combination of die cast aluminum properties ensures that components remain reliable and functional over time, even under demanding conditions.

In conclusion, high pressure aluminum die casting has revolutionized the manufacturing of precision parts across various industries, providing businesses with cost-effective, high-quality solutions. Whether it's partnering with experienced aluminium die casting companies, understanding aluminium die casting price factors, or ensuring the durability of aluminium die casting components, this casting method offers significant advantages in terms of precision, strength, and versatility. With its exceptional die cast aluminum properties, businesses can confidently rely on aluminum die casting for creating parts that meet the highest standards of quality and performance.

-

Why Choose OEM Spark Plugs for Optimal Engine PerformanceNewsJul.16,2025

-

Unlock the Power of Die CastingNewsJul.16,2025

-

The Power of Sand Casting for Your Manufacturing NeedsNewsJul.16,2025

-

The Excellence of Precision CastingsNewsJul.16,2025

-

Maximize Efficiency with High-Quality Stamping PartsNewsJul.16,2025

-

Enhance Your Manufacturing with Aluminium Die CastingsNewsJul.16,2025