Лют . 18, 2025 00:29

Back to list

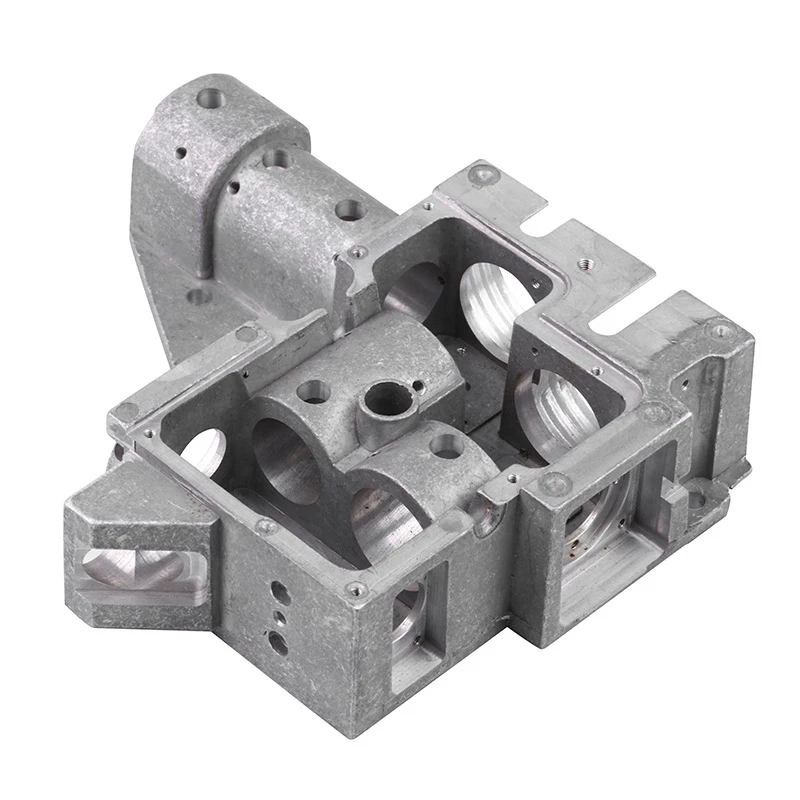

Oem Round Hole Flange Bracket

Custom metal stampings play a pivotal role in various industries, serving as a cornerstone in manufacturing and production processes. Precision, durability, and adaptability are the key attributes that define these components, making them indispensable in sectors ranging from automotive to electronics. This article delves into the comprehensive world of custom metal stampings, highlighting the intricate blend of experience, expertise, authoritativeness, and trustworthiness that manufacturers bring to the table.

Trustworthiness is the bedrock upon which all successful manufacturing relationships are built. Transparency in processes, pricing, and communication fortifies this attribute, allowing clients to have clarity and confidence in their transactions. Reliable delivery schedules, consistent quality, and responsive customer service further enhance the client's trust. Moreover, sustainability has become an integral part of the manufacturing landscape, driving companies to adopt eco-friendly practices throughout the production process. By prioritizing sustainable sourcing of materials and implementing green manufacturing processes, manufacturers not only build trust with their clients but also contribute positively to the environment. Custom metal stampings serve a wide array of industries, each with distinct demands and challenges. In the automotive sector, for instance, components need to ensure performance and safety under dynamic conditions. Electronics require precision stampings to facilitate miniaturization and integration of devices. Medical devices demand components that exhibit strict adherence to hygiene and safety standards. Aerospace parts need to withstand extreme stress and environmental conditions. Each sector benefits from the tailored solutions provided by manufacturers of metal stampings, who bring expertise and innovation to the forefront of each project. In conclusion, custom metal stampings are more than just components; they are the embodiment of skilled craftsmanship, technological prowess, and reliable service. Through a deep-seated understanding of materials and processes, manufacturers deliver tailored solutions that address the unique challenges of diverse industries. By ensuring exceptional design, quality, and functionality, they build lasting relationships with their clients. As production demands evolve, the capacity to adapt, innovate and lead with authority remains paramount, solidifying the role of custom metal stamping manufacturers as trusted partners in industry advancements.

Trustworthiness is the bedrock upon which all successful manufacturing relationships are built. Transparency in processes, pricing, and communication fortifies this attribute, allowing clients to have clarity and confidence in their transactions. Reliable delivery schedules, consistent quality, and responsive customer service further enhance the client's trust. Moreover, sustainability has become an integral part of the manufacturing landscape, driving companies to adopt eco-friendly practices throughout the production process. By prioritizing sustainable sourcing of materials and implementing green manufacturing processes, manufacturers not only build trust with their clients but also contribute positively to the environment. Custom metal stampings serve a wide array of industries, each with distinct demands and challenges. In the automotive sector, for instance, components need to ensure performance and safety under dynamic conditions. Electronics require precision stampings to facilitate miniaturization and integration of devices. Medical devices demand components that exhibit strict adherence to hygiene and safety standards. Aerospace parts need to withstand extreme stress and environmental conditions. Each sector benefits from the tailored solutions provided by manufacturers of metal stampings, who bring expertise and innovation to the forefront of each project. In conclusion, custom metal stampings are more than just components; they are the embodiment of skilled craftsmanship, technological prowess, and reliable service. Through a deep-seated understanding of materials and processes, manufacturers deliver tailored solutions that address the unique challenges of diverse industries. By ensuring exceptional design, quality, and functionality, they build lasting relationships with their clients. As production demands evolve, the capacity to adapt, innovate and lead with authority remains paramount, solidifying the role of custom metal stamping manufacturers as trusted partners in industry advancements.

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES