aluminium alloys for pressure die casting

Aluminium Alloys for Pressure Die Casting

Pressure die casting is a highly efficient manufacturing process used to produce complex metal components with excellent dimensional accuracy, surface finish, and mechanical properties. Among the various materials suitable for this process, aluminium alloys stand out due to their unique combination of lightweight, strength, and corrosion resistance. This article delves into the characteristics of aluminium alloys used for pressure die casting, their benefits, and common applications.

Importance of Aluminium Alloys

Aluminium is the second most widely used metal in the world after steel, and its alloys play a crucial role in many industries, including automotive, aerospace, consumer goods, and electronics. The lightweight nature of aluminium allows manufacturers to reduce the overall weight of products, leading to improved fuel efficiency in transportation applications. Additionally, aluminium alloys exhibit notable strength-to-weight ratios, making them ideal for structural applications where minimizing weight is essential without compromising on strength.

Common Aluminium Alloys for Die Casting

The most commonly used aluminium alloys for pressure die casting are typically classified into two main categories the 3xx.x series and the 4xx.x series.

1. 3xx.x Series This series, containing silicon as the primary alloying element, is favored for its high fluidity, making it excellent for filling intricate mold designs. The 319 and 356 alloys are the most popular within this category. They possess desirable mechanical properties, including good corrosion resistance and excellent strength at elevated temperatures, which is critical for automotive engine components.

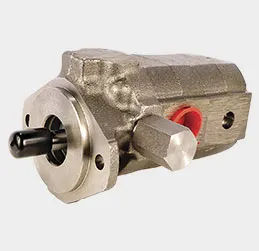

2. 4xx.x Series Primarily alloyed with silicon, these materials—such as 413 and 444—are known for their lower thermal expansion and higher wear resistance. These properties make them particularly well-suited for high-performance applications where durability is paramount, such as pump housings and compressor parts.

Each aluminium alloy has unique characteristics that make it suitable for specific applications, and manufacturers often select the alloy based on performance requirements, climatic conditions, and other factors affecting the end product's performance.

Benefits of Using Aluminium Alloys

aluminium alloys for pressure die casting

The advantages of using aluminium alloys for pressure die casting include

- Weight Reduction Aluminium is significantly lighter than other metals like steel, which helps in reducing the weight of end products. This is advantageous in industries where reducing weight can lead to enhanced performance and efficiency.

- Enhanced Corrosion Resistance Aluminium alloys possess natural corrosion resistance due to the formation of a protective oxide layer, which extends the life of components used in harsh environments.

- Good Conductivity Aluminium exhibits excellent thermal and electrical conductivity, making it a suitable choice for applications requiring efficient heat dissipation or electrical connections.

- Recyclability Aluminium alloys are highly recyclable, which contributes to the sustainability of the manufacturing process. Recycling aluminium requires significantly less energy compared to producing new aluminium from ore.

- Cost-Effectiveness While the initial investment for die casting equipment can be high, the long-term savings through reduced material waste and faster production times make aluminium die-cast components economically viable.

Applications of Aluminium Die Castings

Aluminium alloys for pressure die casting are utilized across a myriad of applications. In the automotive industry, they're commonly used for engine blocks, transmission cases, and structural components. In the aerospace sector, lightweight yet robust elements such as brackets and panels and housings are made using these alloys to maintain performance standards. Consumer electronics, including casings and housings for devices, also benefit from the properties of aluminium die castings, contributing to both aesthetic and functional designs.

The versatility, weight-saving capabilities, and excellent mechanical properties of aluminium alloys highlight their importance in modern manufacturing processes. As industries seek to innovate and improve performance, the demand for high-quality aluminium die-cast components is only expected to grow, making it an exciting area for continued research and development.

In conclusion, aluminium alloys for pressure die casting offer a range of benefits that align with the demands of various industries. Their exceptional properties and broad applicability ensure that they will remain a critical material choice for manufacturing both now and in the future.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025