Oca . 15, 2025 01:57

Back to list

x casting

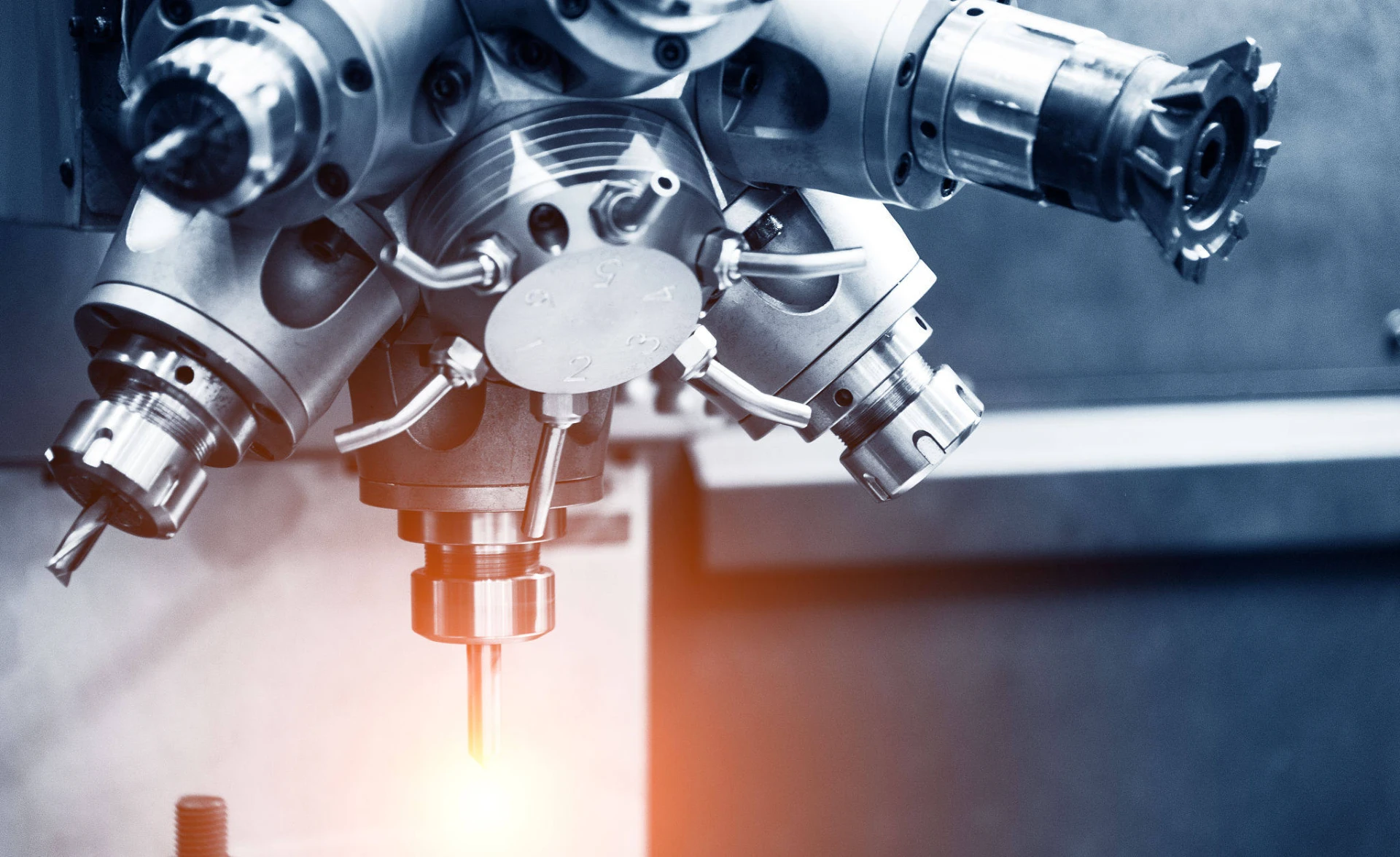

The concept of X Casting has captured the attention of industry experts and enthusiasts alike, making waves in the realm of manufacturing and materials engineering. As an authority in the sphere of innovative product development, it's imperative to delve into the intricacies of X Casting, which has redefined the landscape of production processes with its unparalleled precision and efficiency.

From an authoritative perspective, the adoption of X Casting is being championed by leaders in manufacturing technology. Global corporations are investing heavily in research and development to integrate X Casting into their production lines to stay ahead in an increasingly competitive market. This commitment is reflected in partnerships with academic institutions and research bodies that specialize in materials science and engineering. By fostering these collaborations, the industry is witnessing unprecedented advancements in casting capabilities, making X Casting a cornerstone in modern manufacturing strategies. When examining trustworthiness, X Casting presents a compelling case. The technique enhances quality assurance protocols by incorporating real-time monitoring technologies that track every stage of the casting process. Through the use of sensors and data analytics, any deviations from the desired specifications are immediately identified and rectified, ensuring the highest standards of quality are consistently met. This level of scrutiny cultivates a high degree of confidence among end-users, reinforcing the reliability and performance of products fashioned through X Casting. In summary, X Casting stands at the forefront of contemporary manufacturing, offering unparalleled benefits that cater to the demands of cutting-edge product development. By harmonizing experience from seasoned engineers, extensive expertise in material sciences, authoritative industry endorsements, and an unwavering commitment to trustworthiness, X Casting is poised to revolutionize the future of manufacturing. As stakeholders across the industry landscape adopt this transformative technique, the potential for innovation is boundless, paving the way for a new era of precision engineering and sustainable production practices.

From an authoritative perspective, the adoption of X Casting is being championed by leaders in manufacturing technology. Global corporations are investing heavily in research and development to integrate X Casting into their production lines to stay ahead in an increasingly competitive market. This commitment is reflected in partnerships with academic institutions and research bodies that specialize in materials science and engineering. By fostering these collaborations, the industry is witnessing unprecedented advancements in casting capabilities, making X Casting a cornerstone in modern manufacturing strategies. When examining trustworthiness, X Casting presents a compelling case. The technique enhances quality assurance protocols by incorporating real-time monitoring technologies that track every stage of the casting process. Through the use of sensors and data analytics, any deviations from the desired specifications are immediately identified and rectified, ensuring the highest standards of quality are consistently met. This level of scrutiny cultivates a high degree of confidence among end-users, reinforcing the reliability and performance of products fashioned through X Casting. In summary, X Casting stands at the forefront of contemporary manufacturing, offering unparalleled benefits that cater to the demands of cutting-edge product development. By harmonizing experience from seasoned engineers, extensive expertise in material sciences, authoritative industry endorsements, and an unwavering commitment to trustworthiness, X Casting is poised to revolutionize the future of manufacturing. As stakeholders across the industry landscape adopt this transformative technique, the potential for innovation is boundless, paving the way for a new era of precision engineering and sustainable production practices.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES