Şub . 20, 2025 08:26

Back to list

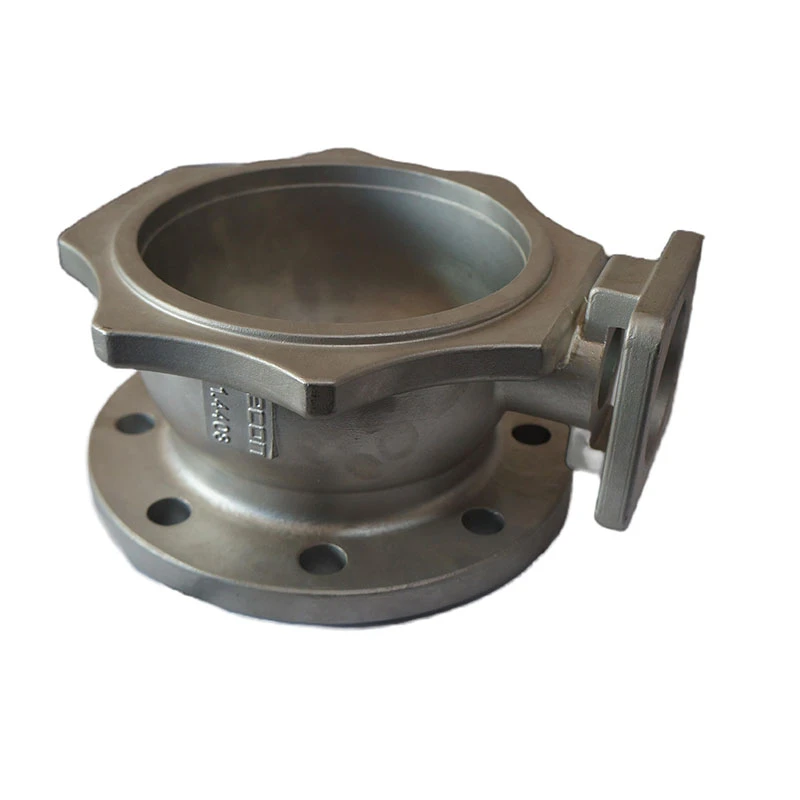

auto parts carbon steel investment precision casting manufacturer

Rubber stamp parts, often overlooked in the intricate world of office supplies, are essential components that contribute significantly to the functionality, durability, and efficiency of rubber stamps. Understanding these parts, their roles, and how quality impacts the overall performance of rubber stamps can provide valuable insights for businesses reliant on these tools for daily operations.

The mount, while often taken for granted, serves as the foundation for the die and the handle. A robust mount ensures alignment and stability during stamping, preventing uneven impressions. Manufacturers emphasize the use of durable materials like high-grade plastics or woods to enhance longevity and support. Feedback from long-term users of top-grade mounts frequently highlights the reduced need for replacements and repairs, testifying to the importance of this component in saving operational costs over time. Integral to the stamping process is the ink pad. Available in various formulations—water-based, oil-based, and even quick-drying options—ink pads are critical in determining the vibrancy and longevity of the stamps. Expertise in this area, as shared by seasoned stationers, suggests selecting ink pads that are compatible with the surface to be stamped and the material of the die. Leading industry reviews and laboratory tests often point towards specialized ink that ensures no smudging and sharp impressions, enhancing document professionalism and aesthetic qualities. Building trust with consumers and ensuring the highest standards of stamp functionality relies on transparency in the sourcing and manufacturing of rubber stamp parts. Established manufacturers often share their commitment to quality through certifications and customer testimonials, providing users with the confidence to invest. In-depth research into the production methods and materials used in making these parts can aid users in making informed choices. In conclusion, delving into the specifics of rubber stamp parts underscores the blend of experience, expertise, and authority needed to produce a reliable product. Businesses and casual users alike benefit from recognizing the importance of each component's quality, which ultimately assures trustworthiness and efficiency in their day-to-day operations. Emphasizing the expertise in design and material selection of rubber stamp parts ensures their longevity and effective use, marking the difference between ordinary and exceptional stamping solutions.

The mount, while often taken for granted, serves as the foundation for the die and the handle. A robust mount ensures alignment and stability during stamping, preventing uneven impressions. Manufacturers emphasize the use of durable materials like high-grade plastics or woods to enhance longevity and support. Feedback from long-term users of top-grade mounts frequently highlights the reduced need for replacements and repairs, testifying to the importance of this component in saving operational costs over time. Integral to the stamping process is the ink pad. Available in various formulations—water-based, oil-based, and even quick-drying options—ink pads are critical in determining the vibrancy and longevity of the stamps. Expertise in this area, as shared by seasoned stationers, suggests selecting ink pads that are compatible with the surface to be stamped and the material of the die. Leading industry reviews and laboratory tests often point towards specialized ink that ensures no smudging and sharp impressions, enhancing document professionalism and aesthetic qualities. Building trust with consumers and ensuring the highest standards of stamp functionality relies on transparency in the sourcing and manufacturing of rubber stamp parts. Established manufacturers often share their commitment to quality through certifications and customer testimonials, providing users with the confidence to invest. In-depth research into the production methods and materials used in making these parts can aid users in making informed choices. In conclusion, delving into the specifics of rubber stamp parts underscores the blend of experience, expertise, and authority needed to produce a reliable product. Businesses and casual users alike benefit from recognizing the importance of each component's quality, which ultimately assures trustworthiness and efficiency in their day-to-day operations. Emphasizing the expertise in design and material selection of rubber stamp parts ensures their longevity and effective use, marking the difference between ordinary and exceptional stamping solutions.

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES